In recent years, the popularity of lithium-ion (Li-ion) batteries has grown significantly. They are found in devices ranging from cellphones and laptops to even cars. This is largely due to advantages such as higher energy density and voltage capacity, as well as lower self-discharge rates compared to other rechargeable batteries.

However, if we expect this technology to assume an important role in defining the future of transportation and energy storage, the issue of capacity fade in Li-ion batteries needs to be addressed.

Capacity fade (or capacity loss) in Li-ion batteries refers to the reduction in performance that occurs in the battery over the course of its lifetime. Battery performance declines with time and use. Eventually, the performance becomes unacceptably low, rendering the battery unusable.

Capacity fade has especially great implications in automotive applications, since the battery cost is fairly high and customers have largely come to expect a service life that compares favourably to combustion engines.

As per the US Advanced Battery Consortium, an electric vehicle (EV) battery is expected to have a lifetime of 15 years and function up to 1,000 cycles. For EV manufacturers to work toward this goal, they need to have the ability to understand and accurately predict capacity fade.

The considerable complexity of Li-ion batteries and the interplay between their physical and chemical phenomena make this a difficult task. In such a scenario, modelling and simulation play an important role in providing much-needed understanding.

Understanding capacity fade

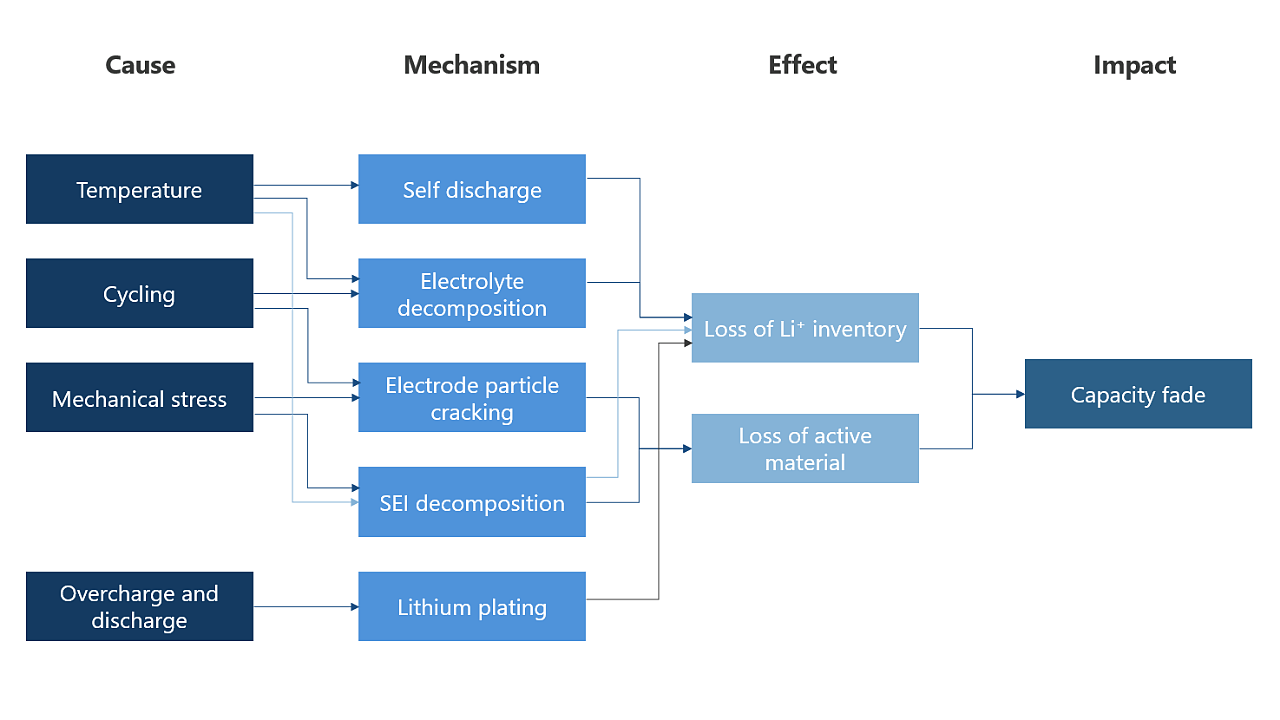

There are several underlying reasons that lead to capacity fade in a Li-ion battery. For instance, high operating temperature can be a big cause of aging, in addition to factors such as cycling, overcharge, discharge, and mechanical stresses.

Battery aging can occur due to either calendar aging or cycle aging. Calendar aging is a function of the length of time that the battery is used. However, the self-discharge rates of a cell also depend on parameters such as the operating temperature and state of charge (SOC). Several operational conditions can lead to accelerated capacity fade in Li-ion batteries.

Repeated cycling can lead to decomposition of the electrolyte. Repeated intercalation and de-intercalation during charge and discharge can also lead to expansion and contraction of electrode particles, which in turn can lead to electrode particle cracking. This can bring about a decomposition of the initial solid electrolyte interphase (SEI) layer followed by an “uncontrolled” increase in the SEI layer.

SEI layer growth is one of the major reasons for cell degradation. In general, the SEI layer is useful, since it protects the anode against degradation, thus ensuring stable performance. However, when this layer is subjected to repeated cycling and elevated temperatures, it can become unstable and see uncontrolled growth.

Overcharge and discharge can also lead to lithium plating, which in turn results in the loss of cyclable lithium in the cell. It should also be noted that all of the phenomena discussed here are highly temperature dependent, with most of them accelerating at higher temperatures.

For instance, studies show that cell life can reduce to half, when the operating temperature is maintained at 35° C instead of 25° C. However, lower temperatures can also be detrimental to certain aspects of battery performance. As an example, charging at low temperatures can accelerate lithium plating. The various phenomena involved, and their interdependence, can be understood either by performing extensive experimentation, mathematical modelling, or physics-based modelling.

Modelling capacity fade

Experiments, often costly and time consuming are impractical, when it comes to understanding capacity fade. Besides, experimental results fall short compared to the physical insights that electrochemical and mathematical modelling affords. Therefore, modelling and simulation play a crucial role in designing experiments as well as in evaluating the results from experiments. Experimentation is reserved for validation of the models.

Modelling and simulation can provide pertinent insights into mechanisms such as lithium plating, particle cracking, and electrolyte decomposition. These can help in understanding the impact of factors such as SEI layer growth and Li inventory on capacity fade, thus serving as a reliable guideline in the development of strategies to mitigate capacity fade for given drive cycles.

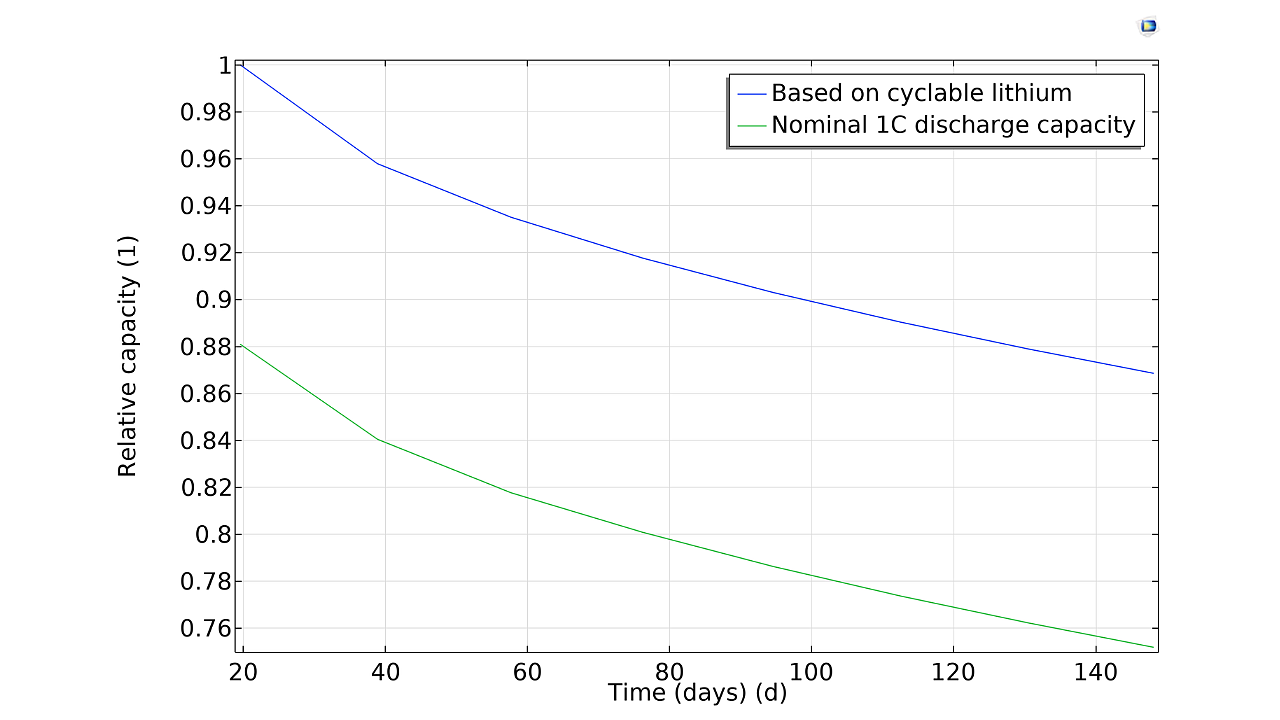

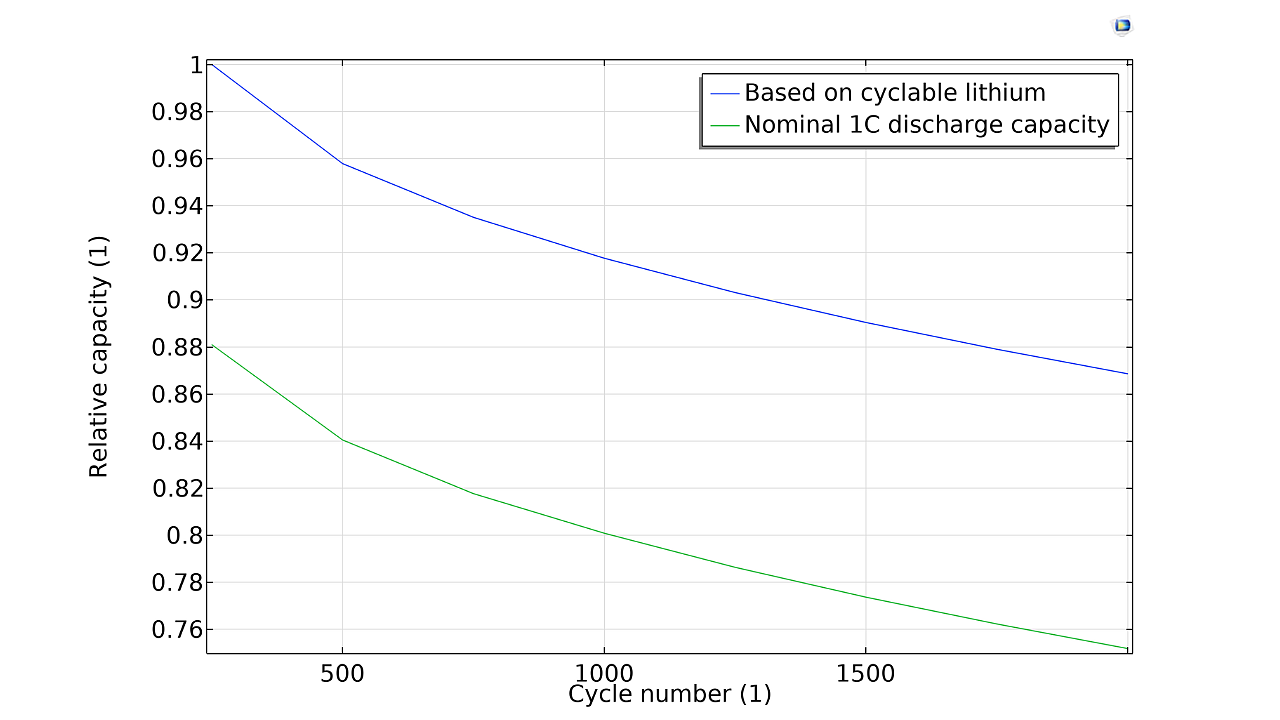

For example, Figure 2 shows how the capacity based on the amount of cyclable lithium and the nominal 1C discharge capacity decrease continuously. While the fade rate is higher during the initial cycles, both capacities decay similarly — about 20% during the 2,000 cycles of the study. This indicates that a loss of lithium, rather than an increased film resistance due to the SEI layer growth, is the primary contributor to the 1C discharge capacity fade.

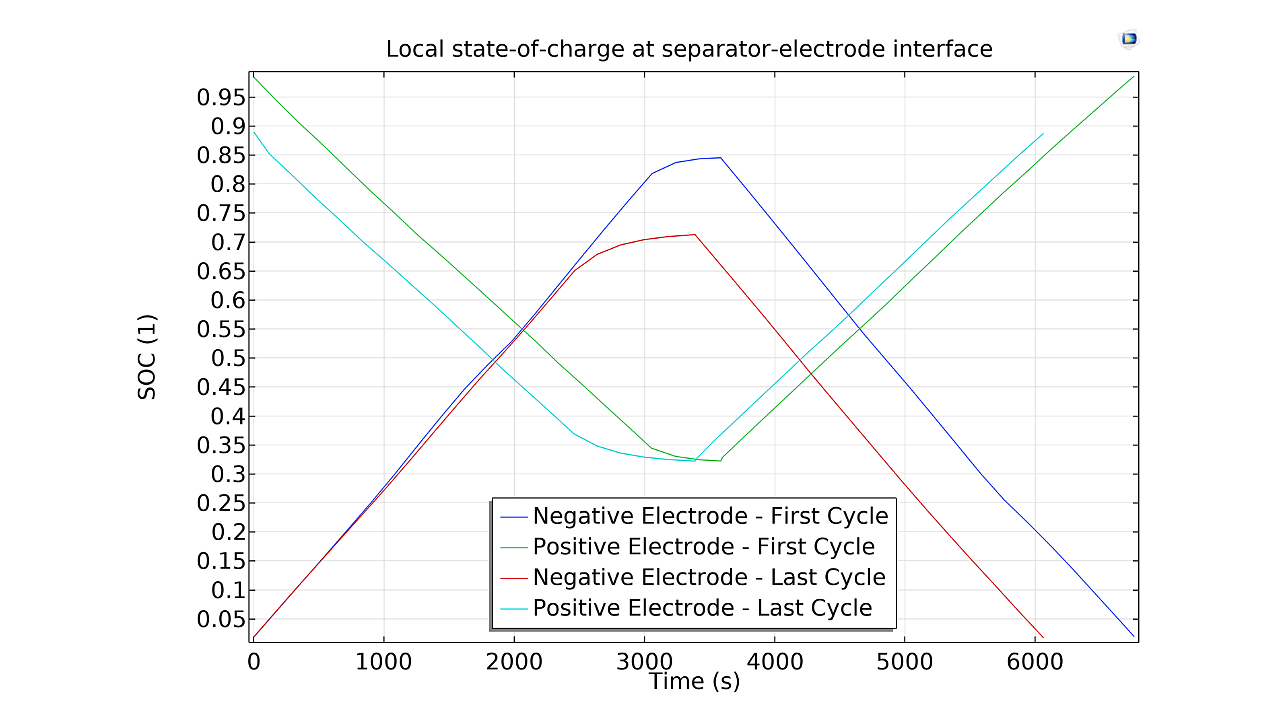

In Figure 3, we can see that the anode displays a relatively greater capacity fade than the cathode during discharge. The figure shows the local SOC at both the cathode and anode for the first and last cycles of the study. This information can help in deciding the cooling strategy that battery users can adopt for their packs. Capacity fade can also be minimised based on predictions of battery hotspots for different operating conditions, such as SOC and charge and discharge rates.

In cases such as system-level models or in on-board models that do not lend themselves to a full analysis of the electrochemistry and physics phenomena, simpler mathematical models, or “lumped models”, can be used. These models are typically based on validated multiphysics models. They are useful to predict capacity fade and its causes on the basis of measured data and by performing parameter estimations. Within the range of calendar and cycle life data used in the development of these models, lumped models can quickly provide useful insights for capacity fade at both the cell and pack level.

In summary, modelling and simulation have an important role to play in better understanding capacity fade. By providing descriptions at the microscopic level, high-fidelity multiphysics modelling can enable battery manufacturers and battery users to understand the impact of various parameters. These include temperature, SOC, voltage, and current density during charge and recharge, numbers of cycles, and other operating conditions that may affect capacity fade. Eventually, this depth of understanding can help address the issue of capacity fade effectively.

About the Author: Dr Vineet Dravid is Managing Director, COMSOL India.