Manish Bhatnagar drives strategy, operations and governance structures for all SKF group companies in India. He has nearly three decades of experience in strategic leadership and business operations, and his prior experience includes stints at Unilever, GE, and Danaher. Having lived and worked in Asia, Europe, and the US, he brings a strong global perspective along with local customer-centricity to drive execution and results.

This year SKF is celebrating 60 years of its operations in India. What are the significant milestones?

With a business spanning across 40 industries, SKF has been on a journey to become a market leader by delivering value-added products and solutions. These include bearings, seals, and lubrication systems and rotating shaft services and solutions for machine health assessment, reliability engineering, and remanufacturing.

Over the years, we have evolved from being a pioneer ball bearing manufacturing company to a knowledge-driven engineering company helping customers achieve sustainable and competitive business excellence.

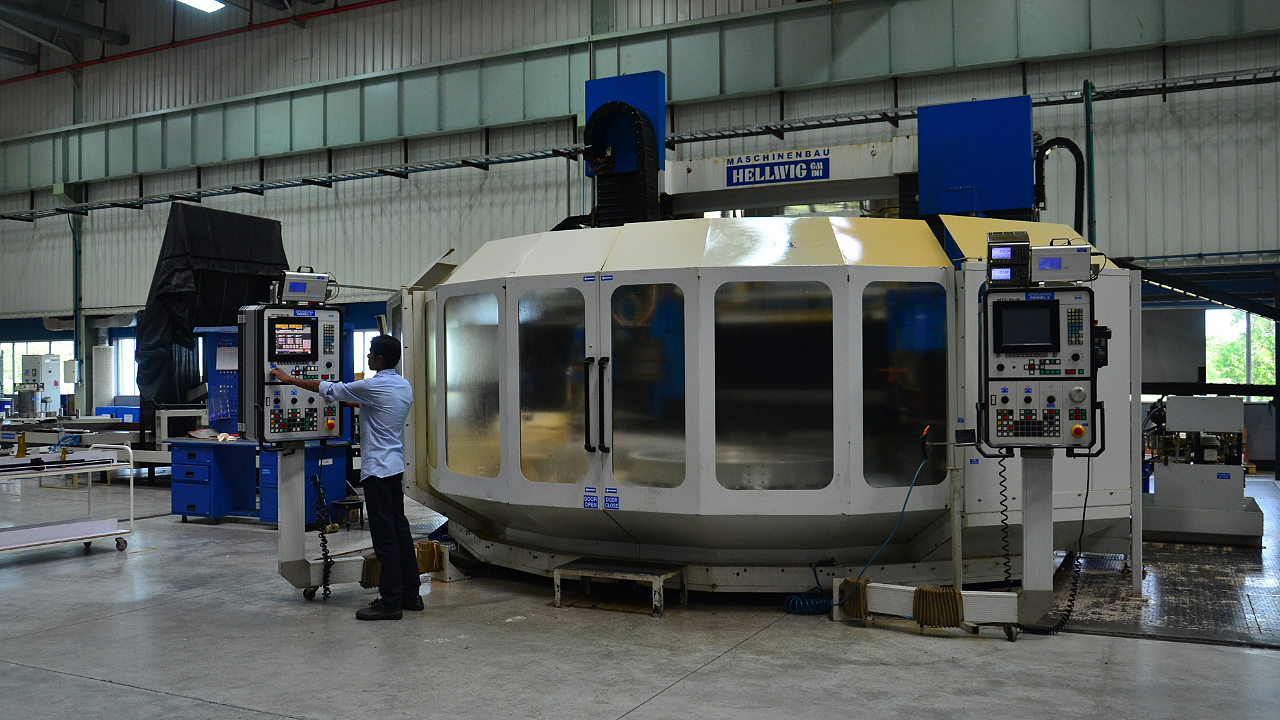

As we take a stride towards a promising future, we have laid down strategic priorities that comprise digitalisation, new business models, innovation, world-class manufacturing, clean-tech, and a future workforce. In India, we have been clocking 15% growth in revenue and operating margins for the past couple of years.

How has this evolution benefitted your customers and your company per se?

Being a knowledge-based company, we leverage information, expertise and innovative solutions to achieve a competitive advantage. Over the recent years, SKF has evolved from a product-based bearing and services supplier to a data-driven systems solutions provider, focusing on addressing customers’ specific needs rather than offering one-size-fits-all type solutions.

How do you drive this?

We have two strategically different value propositions. On the one hand, SKF provides products that meet the customer's specific performance requirements, delivered at the requested time, at a competitive cost.

On the other hand, we offer additional solutions to help customers improve their Rotating Equipment Performance (REP). Here, the customers see the need to reduce operating costs and to run their machines trouble-free, without unexpected downtime and with their equipment reaching its expected operating life. With REP the customer needs to pay a monthly fee rather than the cost of the product, and we get paid based on the performance we deliver.

We essentially are moving from selling products to selling performance and uptime. We win when the customer wins, and we take risks along with the customer.

How do you see this fiscal pan out for SKF India?

While we entered 2021 with a robust balance sheet, deep customer relationships, a strong supplier network, and strategically positioned business, the country was severely impacted by the pandemic's second wave. Unlike in 2020, our manufacturing facilities were not completely shut down during this second wave, and we continued supporting our customers by delivering the products on time.

The effects of the second wave of COVID-19 have not changed our strategy, and I remain bullish on the growth opportunities ahead. However, given the current macroeconomic situation, we expect FY21 to be difficult, particularly in the first two quarters, as we compare ourselves to pre-COVID-19 quarters last year. We remain hopeful for a timely and efficient vaccination programme and a return to pre-COVID-19 levels of business.

What are your current product offerings to different segments?

We have a wide product portfolio of bearings, seals, and lubrication systems in the industrial segment, coupled with rotating equipment solutions and remanufacturing. We cater to over 40 industries globally, directly and indirectly, through a network of distributors.

Particularly in Railways, we offer solutions for a wide range of wheelset designs for all kinds of railway rolling stock. This includes high-speed trains, diesel & electric locomotives, diesel/electrical multiple units, passenger coaches, freight cars and mass transit vehicles like tram cars. From providing design expertise and advanced wheelset bearings, to installing lubrication systems, validating safety requirements, mounting bearings and more – we offer various railway solutions worldwide.

In the automotive segment, we offer customised bearings, seals, and related products for wheel-end, driveline, engine, e-powertrain, suspension, and steering applications for applications in cars, light and heavy trucks, trailers, buses, and two-wheelers. Vehicle aftermarket is supplied with spare parts, both directly and indirectly, through our extensive distribution network. We're well-positioned in wheel-end solutions and in application-driven powertrain solutions and are a leading player in component development for automotive electrification.

A substantial portion of your product portfolio for the automotive segment might vanish with EVs coming in. What are your plans to safeguard your company's business interest?

Although governments around the world are announcing plans to phase out petrol and diesel engines over the coming decades, combustion engines, combined with different levels of hybridisation, are still expected to account for more than 90% of the global passenger car market until at least the middle of the next decade.

SKF is investing in new technological developments and adapting or redesigning conventional bearings to cater to these new demands. That is why many OEMs in Asia, Europe and North America have selected our bearings as part of their electric drivetrain set-up.

The SKF Group has invested SEK 770 million over the past two years in expanding its DGBB (Deep Groove Ball Bearings) manufacturing capabilities in China. The site has also become the company's global R&D centre for these bearings, enabling greater flexibility and speed, when developing bearings for the fast-paced EV market.

Do you see the growth in EVs influencing SKF in India?

The government is encouraging EV adoption and aims that by 2030, EV sales should account for 30% of all new vehicle sales. So far, the impact of EVs on the manufacturers across the automotive value chain has been limited, but as the government brings in stringent regulations and policies and more people switch to electric vehicles, the shift may be more sudden than we expect.

It is, therefore, imperative for OEMs, suppliers, and dealers to be prepared to ride this change brought in by electrification. More focus needs to be on the supply-side that include the manufacturing of critical components of EV technology.

However, given that full electrification will not happen soon and that IC engines are going to be in the play, automakers face the dual challenge of meeting the demands for ICE, which are the profit engine for today's business, while at the same time focusing on EVs to comply with tightening regulatory emissions and fuel-economy targets.

What is the response to SKF's ceramic bearings from the customers in India?

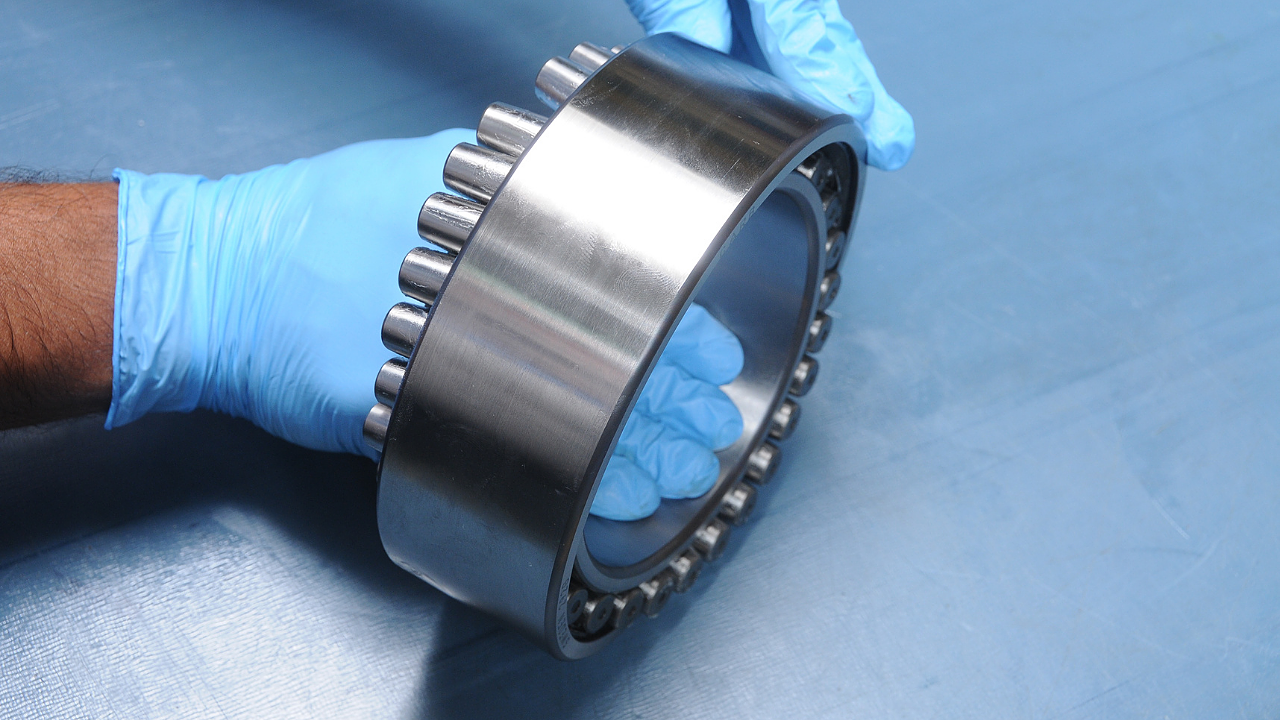

We essentially call them 'Hybrid Bearings' in the SKF ecosystem. The hybrid bearings can substantially improve reliability and robustness and are used in all applications, where the bearings are often exposed to potentially damaging abrasive particles, inadequate lubrication, vibration, or stray electric currents.

We have good customer response as these bearings help extend bearing service life and extend grease, thus reducing the total cost of ownership. For these vehicles to work efficiently, the motors that drive them must run at very high speeds – up to 30,000 rpm, or three times the speed of a typical industrial motor. This places enormous strain on the bearings and also leads to current leakage, which can cause pitting on the surfaces of conventional electrically conductive steel bearings, eventually leading to catastrophic failure.

Made of naturally insulating ceramics, the hybrid bearings negate this issue. These bearings are 40% less dense than steel equivalents (enabling them to run at cooler temperatures), have 10 times the service life, and require less lubrication. Presently, we have a great demand for these bearings from the railways, wind, and machine tool industry. We hope for greater demand with the advancement of the EV industry in India.

How is ‘maintenance-free’ bearing fairing in your product portfolio?

The increased capacity of machinery, in combination with the need to reduce operating costs, is resulting in demand for longer service life, higher load-carrying capacity and reduced effort for maintenance.

We introduced the Extended Life Plain Bearings, the first type of plain spherical bearings to combine the advantages of self-lubricating, so-called maintenance-free bearings and the robustness of steel/steel plain bearings. Additionally, this newest plain bearing is helping to reduce environmental impact significantly and the total cost of ownership. These maintenance-free bearings have high demands due to the benefits they offer to OEMs and end-users alike, such as minimal maintenance and reduced lubricant consumption to optimised costs as well as environmental footprint. It's simply the future of reliable operations.

What is SKF's contribution to the aviation sector in India?

In India, we have been leading the aerospace market for 80 plus years. We supply products to the leading helicopter, fighter aircraft, and aerial defence manufacturers in the country – both in the public and private sector. Each of the approximately 700 civil aircrafts in India is powered by SKF.

What are SKF's activities in shipbuilding activities?

Globally, SKF is active throughout the marine industry, with particular strengths in the merchant, offshore/workboat and passenger/cruise sectors, amongst others. In fact, for more than 70 years, SKF has applied its expertise to critical marine components with marine solutions designed to provide easy, reliable, cost-efficient products and services that are intended to keep operations running smoothly. In India, we currently are focused on sectors like metal, cement, paper, textile, automotive, F&B, railways, etc.

Tell us about the aftermarket business?

Around 38% of our revenue comes from the aftermarket. We recently launched our new range of aftermarket products, including chain and sprockets for two-wheelers, timing belts for four-wheelers and steering and suspension for four-wheelers.

Do you see the scope for remanufactured products in India?

SKF focuses essentially on remanufacturing our bearings, which will help to reduce the life cycle cost of industrial equipment. Our factories offer professional capabilities to refurbish, recondition and rework or upgrade the bearings. We possess the capabilities and experience needed to convert older bearings into new ones in the most cost-efficient manner. In fact, we have a solution for every customer's need, be it a minimal repair or an extensive rebuild.

The materials, methods, and machinery required to produce new bearings are used for remanufactured products as well. It results in customers benefiting from the highest levels of quality, working processes, and knowledge applications for their bearings and rotating equipment. Within the automotive sector, we can see enhanced reuse, repair, remanufacturing and recycling practices involving entire value chains. By investing more in design and improving end-of-life management, the industry can capture economic value while reducing its environmental impact.

How have exports been for SKF?

We are invested in India for India; hence, only a small percentage of what we manufacture is exported, and that too mostly to European countries. In FY21, around 6% of our revenue was from exports.