Hero ECycles has invested INR 400 crore in developing its new facility located in Hi-Tech Cycle Valley, Ludhiana, Punjab. During a recent media visit, the company noted that about INR 600 crore will be invested more in the facility in two phases.

Abhishek Munjal, Director, Hero Cycles, told Mobility Outlook that the Ludhiana facility is going as originally envisioned. “Despite COVID-19, we managed to deploy the facility well ahead of time,” he said.

Notably, the company can now manufacture 500,000 cycles per annum at the existing facility. The plan, as shared by Navid S Talib, President, and Chief Operating Officer of Hero ECycles, is to manufacture 500,000 cycles this year, followed by a million next year and four million by 2024.

10% Ecycles Production

Currently, about 10% of cycle manufacturing is dedicated to e-cycles. While the focus for ecycles is both on India and international markets, the bigger market for the same, the Hero Ecycles team feels, is Europe and America. E-cycle OEMs located in Europe are not able to meet the demand for e-cycles in the region.

The company shared a report with the media, which noted that Europe had a demand for 21 million Ecycles in 2022. While the Europe-based OEMs were able to manufacture 16.3 million of these, 4.7 million had to be imported.

“This is where we see the opportunity. The quality of e-cycles we make in India is loved in Europe. We want to grab this opportunity and ‘make in India’ for the world. We call it Glocalisation,” explained Munjal.

The demand and anticipated demand forecast for ecycles from the other international markets are also humongous. Presently, valued at around $17 billion, a report by Data Bridge has forecasted the ecycle market to hit the $103 billion mark by 2029. “We aim to be in the top five cycle and e-cycle makers of the world,” Munjal highlighted.

Ecycle Component Manufacturing In India

“Designing, developing, and fabricating e-cycle components here in India is how Hero Ecycles will stay ahead of the curve. We have already started manufacturing many components here, and we will continue to design and develop more,” Munjal noted.

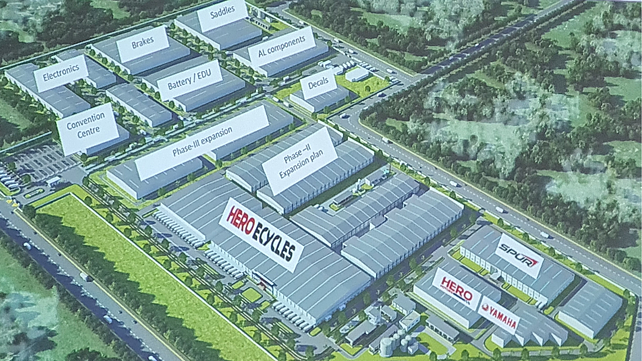

CVP Transmission, Motors, Alloy Parts, Wheel Rims, Frame Parts, and Suspension Forks are some of the Ecycle components that Hero Ecycles is presently manufacturing at its facility in Hi-Tech Ecycle Valley. Notably, the India-based Ecycles OEM had last year announced its collaboration with Yamaha to jointly manufacture electric drive motors for e-cycles in India.

This Yamaha-Hero Ecycles electric motor drive manufacturing facility is being set up in the Hero Cycles Hi-Tech Cycles Valley, and it will be operational by November 2022. It is worth mentioning here that Hero Ecycles owns the majority stake in this one-of-a-kind collaboration.

The company, in 2014, had formed a new entity named Spur to focus solely on ecycles component manufacturing. Abhishek Munjal is heading this entity, and he is clear that Spur will not just manufacture components for Hero’s e-cycle brands but also supply the same to all major e-cycle OEMs worldwide.

But it’s not a merry-go-round for the OEM as the ecycle battery front is one of its biggest pain points. The company currently imports battery cells from outside, which are packaged as batteries by a third party.

“We are aggressively looking for sourcing battery cells from within India, and are hopeful that we will be able to source the same from here as soon as battery cell manufacturing starts here. Presently, no company in India manufactures these here,” he said.

Whitelabel For Other OEMs

Manufacturing cycles for other brands under the white labelling concept seems to be one of the biggest focuses of Hero Ecycles for driving its next phases of growth. The OEM has already started manufacturing e-cycles for Amazon and Argus. Its first batch of e-cycles was shipped to Europe early this year.

Without taking any brand names, Munjal noted that Hero Ecycles is in talks with many international brands for manufacturing cycles on a contract (white label) basis. He shared that the company has achieved this feat because of its legacy and the prowess it has created for itself in the space of cycle manufacturing.

“Our cost of manufacturing an ecycle in India is 32% economical than any Chinese company, and over 3% more economical than any other Indian ecycle company. This is because of the amount of localised content we put in cycles and e-cycles here,” said Munjal. He highlighted that investing in developing and manufacturing components locally has helped a lot.

A close look at Hero Ecycles' plan for its facility in the Hi-Tech Cycle Valley reveals that the company is trying to establish its supply chain within the 100 acres it acquired on Ludhiana's outskirts. There are dedicated land parcels for establishing an e-cycles electronics facility, a brakes facility, a saddles facility, and a battery-making facility. The layout seen by Mobility Outlook also mentions separate land parcels for decals and AL components.

Acquisitions & Mergers

Talib further noted that there are more acquisitions and mergers for Hero Ecycles on cards. About eight months back, he took charge of the facility and has already helped Hero Ecycles acquire an India-based start-up in the mobility and connectivity space.

“The deal has been done. We will make the announcement as and when the start-up is completely merged into Hero Cycles. We are open to working with start-ups and any other major company on the e-cycle front,” he noted.

The list of brands operating under the umbrella of Hero Ecycles includes Hero Lectro, Coyote, Viking, HNF, INSYNC, Firefox, BSH, Spur, HewLand, Hero ZF, Concept, and Munjal Kirtu. The OEM’s total manufacturing capacity across all its plants (national and international) is 10.2 million bikes annually.

One more striking factor at the Hero Ecycles’ facility in Cycle Valley Ludhiana is that the majority of individuals working on its shop floor are diploma engineers. The company is also working on automation and has completely automated the paint shop. It has also started investing in opening experience zones for its e-cycles in India.

“E-cycles are not as famous in India as in other parts of the world because people do not know about them, and our aim is to educate people about the same via our experience centres. We would also like to request the Government of India to introduce a PLI for e-cycles as the opportunity is massive,” Munjal noted.

Giving an example of the inclusion of e-cycles in the Delhi Government's electric vehicle subsidy policy, he noted that Hero’s sales of e-cycles have doubled after the same. Munjal expects the same effect on the overall Indian market if e-cycles are involved in incentives policy and a PLI for manufacturing e-cycles is introduced in India.