In a major development for India’s aerospace ecosystem, Tata-Lockheed Martin Aerostructures Limited (TLMAL), a joint venture between Tata Advanced Systems (TASL) and US airframer Lockheed Martin have successfully qualified the first F-16 fighter wing built in India. TASL, the wholly-owned subsidiary of Tata Sons, has grown rapidly in less than a decade, focusing on providing integrated solutions for aerospace, defence, and homeland security. It has now grown its capabilities throughout the entire aerospace value chain from design to whole aircraft assembly, as evidenced most recently with the Airbus C295 order from the Ministry of Defence.

The manufacture of the wing of a high-performance fighter aircraft is another feather in the cap for TLMAL, which can now compete for global F-16 fighting wing orders with other Lockheed Martin suppliers.

Sukaran Singh, MD and CEO, TASL, said, “The successful completion of the fighter wing shipset prototype project is another achievement added to the partnership between Tata Advanced Systems and Lockheed Martin. With this, TLMAL creates a new benchmark in complex and end-to-end defence manufacturing in India that demands utmost precision and quality in all aspects of the process.”

Speaking to Mobility Outlook on the sidelines of the qualification event for the F-16 wing, earlier this week, Singh said that the Tata Group had decided to proceed with F-16 wing production by TLMAL even without an order as it was keen to grow its capability to manufacture increasingly complex aerostructures.

With the Government focused on greater in-country manufacture of defence equipment, the ability to manufacture F-16 wings in India could further boost Lockheed Martin’s offer of the F-21 (a derivative of the F-16) to meet an IAF requirement for 114 new fighter aircraft.

F-16 wing production in India, however, is not contingent on the F-21 being selected to meet the IAF requirement. Lockheed Martin is facing resurgent demand for the latest version of the new F-16 Block 70/72, which five nations have already ordered.

At present, wings for the new production F-16s are built by Israel Aerospace Industries (IAI), which restarted production in September this year. The Israeli firm reactivated an assembly line it had first established in the 1980s. After manufacturing the F-16 wings, IAI transports them to Lockheed Martin’s final assembly line in Greenville, South Carolina, USA.

IAI also produces outer wing boxes for the F-35 5th generation fighter, which Lockheed Martin builds along with wings for the T-38 jet trainer.

Structural Shift

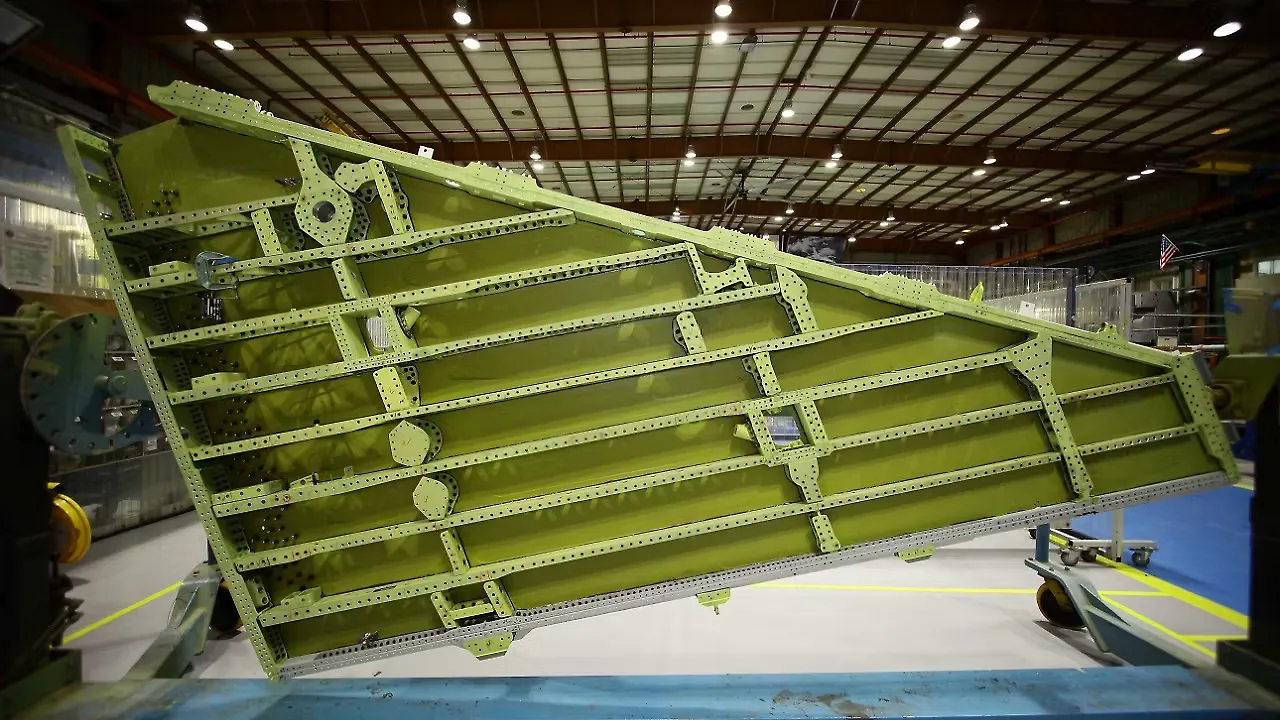

A fighter wing is one of the most technologically complex aerostructures to manufacture. “Through this prototype project, TLMAL demonstrated their manufacturing capabilities & also met Digital Engineering requirements through Wing digitisation,” said Aimee Burnett Lockheed Martin, Vice President, Integrated Fighter Group Business Development.

Unlike the other aerostructures supplied by TLMAL, the fuel-carrying F-16 wing is interchangeable/replaceable that can sustain loads of 9G (nine times the force of gravity) and has a 12,000-hour service life. The successful qualification of the first prototype wing manufactured at TLMAL’s Hyderabad facility showcases its capability to perform detailed part manufacturing and deliver a fully compliant representative fighter aircraft wing shipset.

Since the F-16 has a “wet” wing (a wing with fuel inside), the wing leak test was an extremely challenging test to clear, especially considering the G loads that the wing will experience in operational service. “The team got significant appreciation from Lockheed Martin for passing the very complex, ‘Wing Leak’ test the first time right along with the product quality that we have delivered,” said Masood Hussainy, Head Aerostructures and Aero-Engines, Tata Aerospace and Defence. Also utilised for the F-16 wing manufacture was India’s first state-of-the-art metal-to-metal bonding facility, which was established on TLMAL’s premises in April 2018. The 4,700 square-meter facility enhanced TASL’s capability to manufacture complex aero-structures.

TASL and Lockheed Martin decided to partner together to produce F-16 fighter wings in India for export in September 2018, and both firms worked hard to qualify several Indian companies for the programme resulting in over 70% of the detailed parts now being sourced locally. Among these suppliers is Lakshmi Machine Works, the first Indian private sector firm to supply a 9G capable aerostructure for the programme. Other qualified suppliers include Azad Engineering, Tata Sikorsky Aerostructures, Rangsons Aerospace, Rossel Techsys and Vijayant Metal Finishers.

Industrial Powerhouse

TLMAL was established in 2010 and is the global single-source supplier of C-130J empennage assemblies. These empennages, which consist of the whole tail unit of the aircraft, are installed by Lockheed Martin on all-new Super Hercules aircraft (including those already in service with the IAF). TLMAL has delivered nearly 160 C-130J empennages to date and can produce 24 C-130 empennages annually. TLMAL has also indigenised its C-130 manufacturing by transitioning the production of approximately 2,000 previously imported empennage parts to Tata Sikorsky Aerospace, another Tata-Lockheed Martin joint venture located here.

The Tata Group’s Aerostructures and Aero-Engines business now come under Tata Aerospace and Defence, formed after amalgamating various Tata companies in the Aerospace and Defence sector with more than 4,000 employees. Tata Aerospace and Defence counts six of the top ten aerospace firms globally as its customers and is the global single-source supplier for 20 major aircraft programmes, including the Airbus A320, Boeing 787, Lockheed C130 J, Boeing AH-64E Apache Helicopter and Sikorsky S 92 Helicopter. It also supplies complex aero-engine parts to General Electric and Rolls Royce.