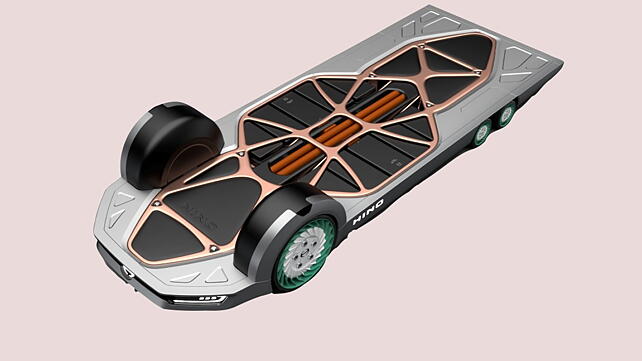

The future modular EV platforms will be flexible and multifaceted, with various vehicle types and shapes built on a single programme, says Frost & Sullivan's recent analysis. These modular EV platforms will help OEMs save the time, effort, and money required to launch new models.

As the automotive industry converges toward connected, autonomous, shared, and electric (CASE) mobility, original equipment manufacturers (OEMs) are working on re-engineering their conventional platforms to accommodate electric vehicle (EV) components such as batteries and motors. However, the industry's transition from a vehicle-centric to a service-centric approach necessitates developing new digital platforms (software, back-haul connectivity, and cloud).

The study, Future Skateboard and Platform Architecture Strategies of EV Companies, examines emerging market trends, platform development's collaborative approach, new business models for platforms, and growth opportunities. The study is part of Frost & Sullivan's Global Mobility Growth Partnership Service programme.

Kamalesh Mohanarangam, Program Manager, Mobility Practice, Frost & Sullivan, said in the future, the automotive industry will not be restricted to traditional vehicle manufacturing methods. The sales will focus on building new downstream sources of revenue, emphasising the users instead of the vehicles.

As the automotive industry shifts from the traditional pyramidal value chain to a flat value chain, mobility companies are sourcing chassis technology and platforms from third parties and integrating their technologies, he said.

The study suggests the market participants focus on the following growth prospects:

To overcome CASE-related challenges, the study suggests the industry participants to develop modular and flexible platforms to offer a number of models without significant investment.

With electrification and autonomy gaining popularity, OEMs need to push purpose-built platforms for EV production to enable the seamless introduction of automation.

The study indicates that the suppliers will need to expand their scope and focus on bringing in X-by-wire systems for spacious cabins. They should ensure that fail-operational functionalities are built into the system to develop and offer products that address evolving hardware architecture and the software consolidation process.

By developing end-to-end software platforms that are scalable and modular, OEMs can make resource sharing a reality, which will lower overall costs and add new capabilities, the study noted.

'Although the initial investment required to develop a dedicated, scalable platform is significantly high, the excessive flexibility this platform offers will offset this investment through economies of scale. Further, the amount of time, investment, and effort required to manufacture different battery electric vehicles (BEVs) on an EV platform is significantly less when compared to other platforms,' Mohanarangam added.

NB: Photo is representational; courtesy: HINO.