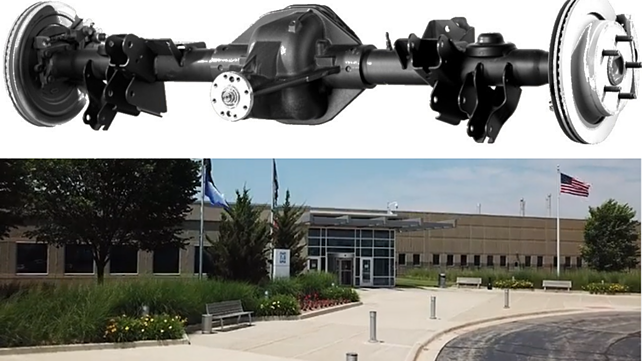

The global technology company supplying systems for passenger cars, commercial vehicles and industrial technology, ZF has announced that its Marysville, Michigan facility secured a contract worth about $6 billion to supply beam axles and axle drives for pick-up trucks. The contract is valid until 2027, and this business win results in more than 800 American jobs, the company said.

The Marysville facility is a state-of-the-art, innovative, clean and climate-controlled building that primarily produces axle drive components for major North American automotive manufacturers.

Used often as rear-axles in pick-up trucks, SUVs and performance sedans, the robust design of the solid beam axles serve as a platform for chassis functions in addition to transmitting vehicle torque.

The axle offers significant weight reduction to the customers due to the aluminium housing and welded crown gear design. Besides, the low-friction bearings optimised hypoid offsets and reduced oil quantity offer improved efficiency. The axles can be equipped with locking differentials and offer a wide range of ratios, while optimised gearing offers better ride performance with reduced noise, vibration and harshness.

Wolfgang Moenig, Vice President, Product Line Axle Drives North America, ZF Group, said the contract signifies a bright future for the Marysville plant, employees and community.

Larry Miner, plant manager, ZF Axle Drives Marysville, said the plant's dedicated team has worked tirelessly to secure a strong future for this facility and its employees. 'ZF is a 105-year-old company with a culture of innovation – that mentality is present in our plants as well, as we look toward meeting the demands of future mobility,' Miner added.