Prashanth Achar began his career with Tata Motors in After Sales Service. Subsequently, he worked with BP group for 24 years. His journey in the automotive and lubricant industry meandered through diverse roles – sales, marketing, strategy, business development and integration within the Asia & Pacific landscape.

Can you update us on the new businesses opportunities that you have received recently?

A big win for us in the OEM space has been the partnership with Honda Motorcycle and Scooter India. We launched the high-performance Repsol-Honda co-branded products, made especially for them. Globally, Honda and our partners – Repsol, Spain – are in a partnership and have been the undisputed leaders in MotoGP racing for 26 years with 20 wins across all championships.

The automotive OEMs space governs close to 40% of the cradle-to-grave lubricant requirement of vehicles. The new vehicle rolls out of the factory with first-fill in the sump, followed by the adult phase of service at the OEM workshops. By the time the vehicle shifts to the bazaar – B2C space, it is in its midlife. We have strategically chosen to build our brand in the B2C space in the short term based on our right to win. We will focus on the OEM space subsequently, with a concerted effort.

We share a very different relationship with OEMs. You will not find us frequently inside the engine sumps in assembly lines yet. However, most of the components would have tasted our products even before reaching the assembly line. As an example, one out of four two-wheeler tyres is manufactured with process oils supplied by us.

We are a fairly large player in metalworking for the automotive industry for most of the components – be it engine blocks or steering handles or gear wheels – they have the signature smell of our products. About 15% of those components in a motorcycle would have been machined, tempered, drilled, honed or coated with our products.

Also, we are one of the leading suppliers of various lubricants to tractor OEMs, agricultural equipment manufacturers, crane manufacturers and tipper segments.

What are your offerings to Industrial and Railway segments?

We offer a complete portfolio of products for the industrial segment, starting from general lubrication to hydraulic, metalworking fluids (like rust preventives, soluble oils, neat cutting oils, cleaners, quenching oils), transformer oils and greases. We are one of the leading suppliers of water-soluble & semi-synthetic coolants in the country. Over a period, we have developed expertise to run the lubricant management for our customers yielding in cost savings, extending the machine life and protecting the environment.

The Research Designs and Standards Organisation (RDSO), Lucknow approves IPOL gear oils, hydraulic oils, lubrication oils and various metalworking fluids after thorough testing and evaluation, which we are supplying to various Indian Railway workshops across the country.

What are the challenges you have faced in FY21?

FY21, simply put, was a year of introspection and innovation. We went to a boot camp and created a four-year strategy to double the profits. Once the vision was clear with the strategic pillars in place, the fit-for-purpose organisation structure was woven around it. ‘People as Agenda’ approach addressed the culture and in making the organisation future-ready. The new set of values – PATH (Passion, Agility, Think Big, and Honesty) underpinned the culture and is getting ingrained across the organisation.

The pandemic forced us to be agile and innovate in developing new businesses as well as cash-flow management. We rolled out Project 4C – Customer-centricity, Cash flow efficiency, Capability building and Communication. To drive the cash-flow efficiency, the company embarked upon the concept of tank-to-bank velocity to ensure the ‘oil in stock is converted to dough in the bank’ in the fastest possible time through the supply chain, sales, and marketing enablers.

The overall industry was down by double digits, as per initial estimates. We drove both top line and bottom line through range selling and twin brand offering IPOL and Repsol at value for money and premium segments. In recessionary times, the Value For Money (VFM) players take a share of premium players.

The heightened industrial activity positively impacted the industrial lubricants demand and automotive lubricants due to goods movement. The tyre industry is booming, given the imports are curtailed. In 2020, we had started a drive to increase reach in Tier 2 and Tier 3 towns, which account for 50% by market size. Agility in appointing distributors virtually and addressing their working capital through channel-finance partners ensured healthy business growth. We started on a major digitisation drive by putting the front-line sales team on the mobile app for sales order booking and tracking.

In the industrial segment, riding on our strength, our strategy was to address all the four quadrants of Ansoff’s Matrix with distinct offers. This helped us in de-risking the overall business as the three business verticals focused on the automotive segment at present. Last year, the drive for the industrial division was to improve the premium product mix through more synthetics and soluble cutting oils.

The RPO (Rubber Processing Oil) business continued to be the leading Indian private player in the category with supply positions to all major tyre makers.

How do you mitigate the recent price hike in raw materials – both base oil and additives?

It is an industry-wide phenomenon, and we are no exception. The base oils have become scarcer, and their prices have gone through an unprecedented slog since November 2020 and are ever-increasing as we speak. We have been watching the cost movements and supply trends and treading cautiously.

We have trained our customer-facing teams to lead the price trend with the correct ‘value engagement.’ Customers appreciate the unprecedented times that we are going through and do support us in ensuring that we progress together.

How do you see FY22 pan out for GPPL?

With the second wave of the pandemic, it will be foolhardy to foretell the economy’s future or the industry. By all estimates, the lubricant industry is likely to contract further in FY22. We are innovating and driving austerity without taking our eyes off the ball. GPPL will be driven by the motto – Passion for Growth. We cannot be myopic, and we will continue the initiatives conceptualised last year into fruition.

People Growth – We believe that people are our biggest assets. We already started the journey of “People as Agenda” by working extensively on capabilities, reward & recognition and building a performance culture.

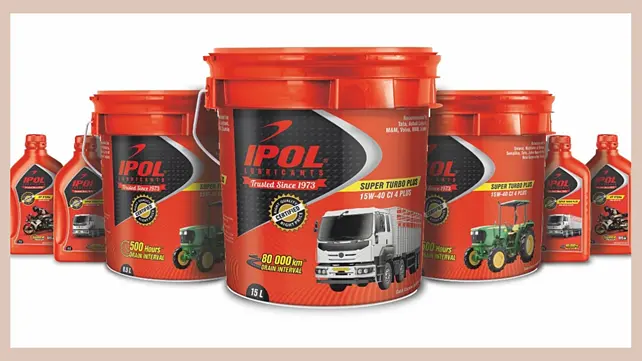

Portfolio Growth – B2B as well as B2C will be the growth engines for the next four years. For FY22, in B2C, high double-digit growth has been articulated through key growth enablers for brands IPOL and REPSOL. We have embarked on the 3R strategy of Reach, Retain and Range. Channel finance will be deployed to improve reach and outlet penetration, while E2E Digitisation from the sales team to mechanic to end customer would address the retention challenge. Portfolio approach will help in completing the range offer in the chosen spaces.

The B2B business will continue to drive volume and move the premium needle. The big idea is to de-risk the business of its current dependence on the cyclical automotive segment. The focus will continue on premium segments like semi-synthetic coolants and speciality greases apart from driving the distribution plan. Capability is being built to grow new segments like cement, paper, plastics, etc.

The challenge for our supply chain teams would be to limit the capital blocked in inventories and make GPPL ‘a lean-mean machine’ through innovation. The cost to serve is being challenged and brought down drastically.

Which segment of lubricants – transportation or industrial – will fuel growth in future and why?

It is both, given that we are a small player in both segments, and the headroom is vast. In automotive, we will be driving both top line and bottom line growth through a portfolio approach. Motorcycle oil will be the key focus segment as it is also the fastest-growing segment in the country. Through our consumer study and R&D capability, we have created bespoke solutions for each segment, and we are investing in brand communications. We are also exploring entry into Sri Lanka and Nepal with our Repsol offer.

In the industrial segment, our strategy is to address all the four quadrants of the Ansoff Matrix with distinct offers. ‘Sell New, Sell More’ is the motto as we have built the capabilities over the last year.

Can you update on your manufacturing facilities?

We specialise in formulating, blending, and marketing industrial & automotive lubricants, process oils, greases and other specialities. Our blend plant at Vasai has an annual capacity of 80,000 MT with a storage capacity of 15,000 MT, one of the largest in the industry.