The all-new hybrid powertrain in the McLaren Artura sets new benchmarks for performance, building on the levels of high-performance hybrid excellence set by the pioneering McLaren P1TM – the world's first hybrid hypercar – and the Speedtail Hyper-GT.

The advanced petrol-electric powertrain delivers a unique combination of throttle-response, acceleration and electric-only, zero-emissions capability. It has been engineered to ensure the supercar excels across the full spectrum of driving experiences, from everyday urban journeys to track day sessions.

According to Geoff Grose, Chief Engineer, McLaren Automotive, the super-lightweight electrified powertrain is at the cutting-edge of high-performance-hybrid technology, engineered to offer all of its advantages, internal combustion and electric power in one package and establish new benchmarks for combined performance and efficiency in the supercar class. 'The 'clean-sheet' design of the Artura has allowed us to focus on how to make this power accessible to the driver and deliver the levels of engagement expected from a McLaren,' he said.

Minimising weight was key to the design of the all-new powertrain. This is hugely important in an electrified supercar and is absolutely aligned with the company's philosophy of super-lightweight engineering that is fundamental to the performance, agility, and driver engagement.

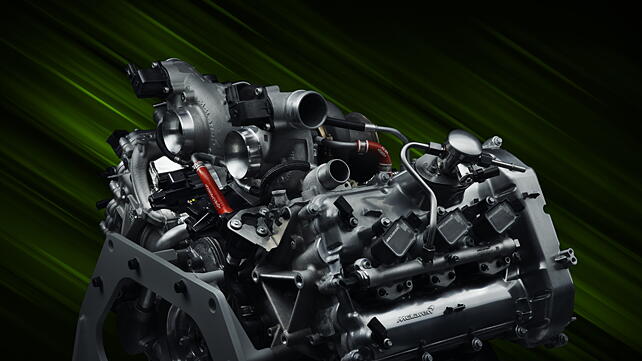

Breaking with the V8 convention established with the first supercar from McLaren Automotive, the 12C, at the heart of the Artura is an all-new, 3.0-liter V6 internal combustion engine. The 120-degree, twin-turbocharged M630 unit allows the most compact packaging possible. A 180-degree angle was considered but dismissed because it would raise the height of the crankshaft and therefore the centre of gravity of the car. The wide angle of the V6 cylinders allows the turbochargers to sit within the banks in a 'hot vee' configuration, which also benefits efficiency as they sit within a straighter - and therefore less restrictive – exhaust layout. Generating 671bhp and 531lb ft of torque, the all-new V6 engine is 7.5inch shorter and 8.7inch narrower than its twin-turbo 4.0-litre V8 – and also 110lbs lighter.

Powertrain Packaging

The cylinder head and block utilise 3D printed cores, allowing uncompromised precision cooling, including a micro-compact 0.08inch cooling passage between the cylinders. The block has directly coated parent bores rather than separate coated liners, into which fuel is injected at 350bar pressure. Shared crankpins enable a very short and stiff crankshaft that allows the M630 to redline at a thrilling 8,500rpm. Since it is designed with the chain drive, the ancillary noise is reduced, allowing the occupants to hear only the V6's distinctive intake and exhaust note, routed via Gasoline Particulate Filters to reduce emissions.

The V6 engine powers the rear wheels via an all-new eight-speed seamless shift transmission that has also been designed for optimising packaging. The gear cluster's length has been reduced by 1.6inch, helped by the use of a nested clutch rather than a parallel unit and the removal of a reverse gear. This function now achieved by the E-motor spinning in the opposite direction. The ultra-compact motor is fully integrated within the transmission bell-housing, delivering torque in-fill and linear acceleration via an E-differential to the rear wheels.

Providing the electric-only capability is a 7.4kWh five-module Lithium Ion energy dense battery pack. Fully-integrated into the Artura's McLaren Lightweight Architecture (MCLA) chassis, the battery pack is positioned low-down in the car behind the driver, incorporated into the floor and protected on three sides by the main carbon fibre structure and from behind by the engine. This positioning also helps to optimise both centre of gravity and the polar moment of inertia, benefitting dynamic agility.