The theme across the world is to ensure that vehicles emit the same on the road as they do at test laboratories, and to reduce the non-conformity factor, it is necessary to have good instrumentation to measure on-road and developing technologies to meet these requirements. Besides, it is necessary to ensure that the lab test cycles represent real-driving, Dr Ameya Joshi, Director - Emerging Technologies, Corning, has said.

Participating in a Dialogue of Global Trends and Regulations in Clean Air Technologies, organised by Mobility Outlook, along with Corning, Dr Joshi said, the main focus should be on cold-start emissions. Critical factors are ensuring that the emissions during the first few minutes of the car running are identical as they do after the engines warm up. These can be achieved by improving standards and technologies, he said.

Small Particles Big Threat

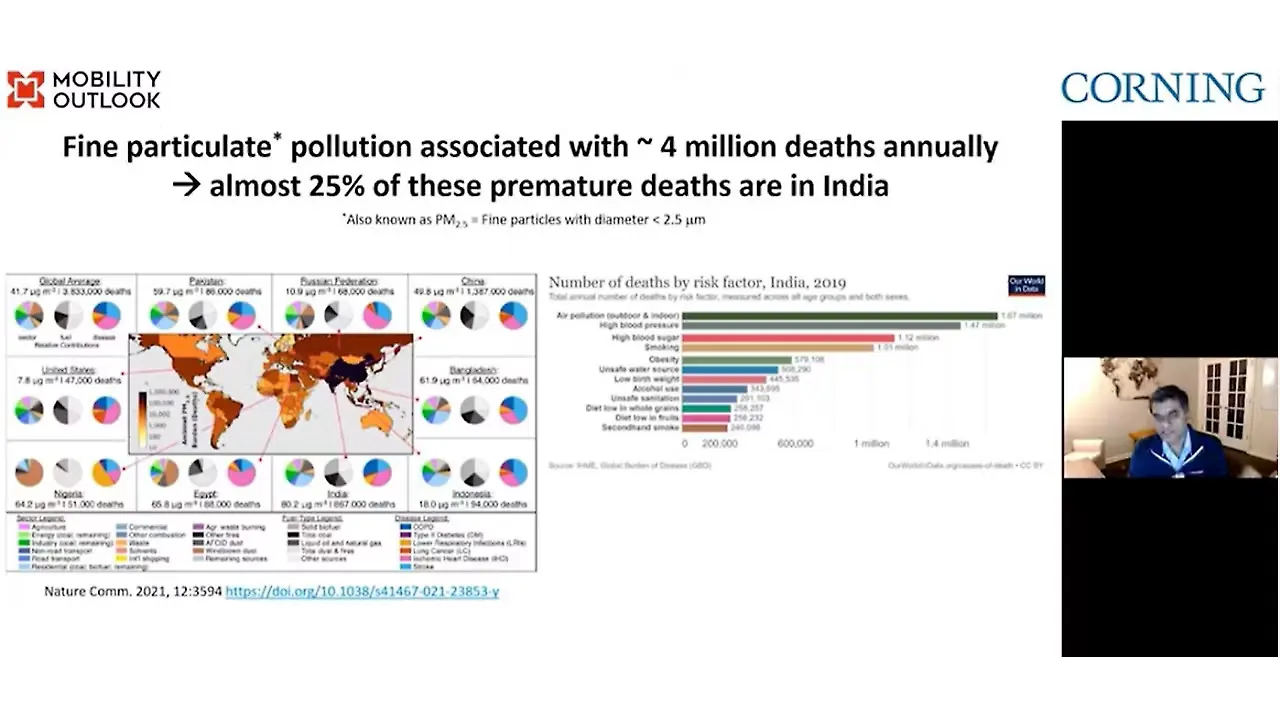

Though there are several factors for pollution, transportation plays a key role. Emissions of NOX, hydrocarbons, CO2 and particulate matter pose a huge challenge as there are still about four million deaths annually linked with this fine particulate pollution that is typically referred to as PM 2.5, or particles below two a half microns.

Tail-pipe emissions from cars are typically in the range of 50 to 150 nanometers, which are much finer than PM 2.5. These are very fine particles that go deep into the lungs and cause a whole host of health issues, cardiovascular diseases, etc. Highly populated countries like India and China are bearing the brunt of these pollution issues, he mentioned.

Air pollution is still by far the highest cause of premature deaths in a few countries, including India and this calls for a dire need to solve the issues pertaining to pollution despite decades of work in improving and regulating emissions.

Five micrograms per meter cube is the latest air quality guideline issued by WHO, however, India currently has the guideline of 40 micrograms per meter cube.

Elaborating on the issues, Dr Joshi said there are greenhouse gases comprising CO2, Methane and Nitrous Oxide, and criteria pollutants such as gas (carbon monoxide, nitrogen oxide, hydrocarbon, formaldehyde etc.) and particulates - number and mass.

Corning provides particulate filters substrates for gas treatment. This covers everything that is regulated, but there are more to be regulated, including black carbon, he said.

Indian Fleet

The Indian fleet is relatively fuel-efficient, he said, as the hydrocarbon and NOX emissions from modern vehicles have reduced by 90% during the last two decades. However, there is room for further improvement. Compared to BS-1, the particulate emissions in BS-6 are 97% low. The main changes are coming from the systems-level and components level, he said.

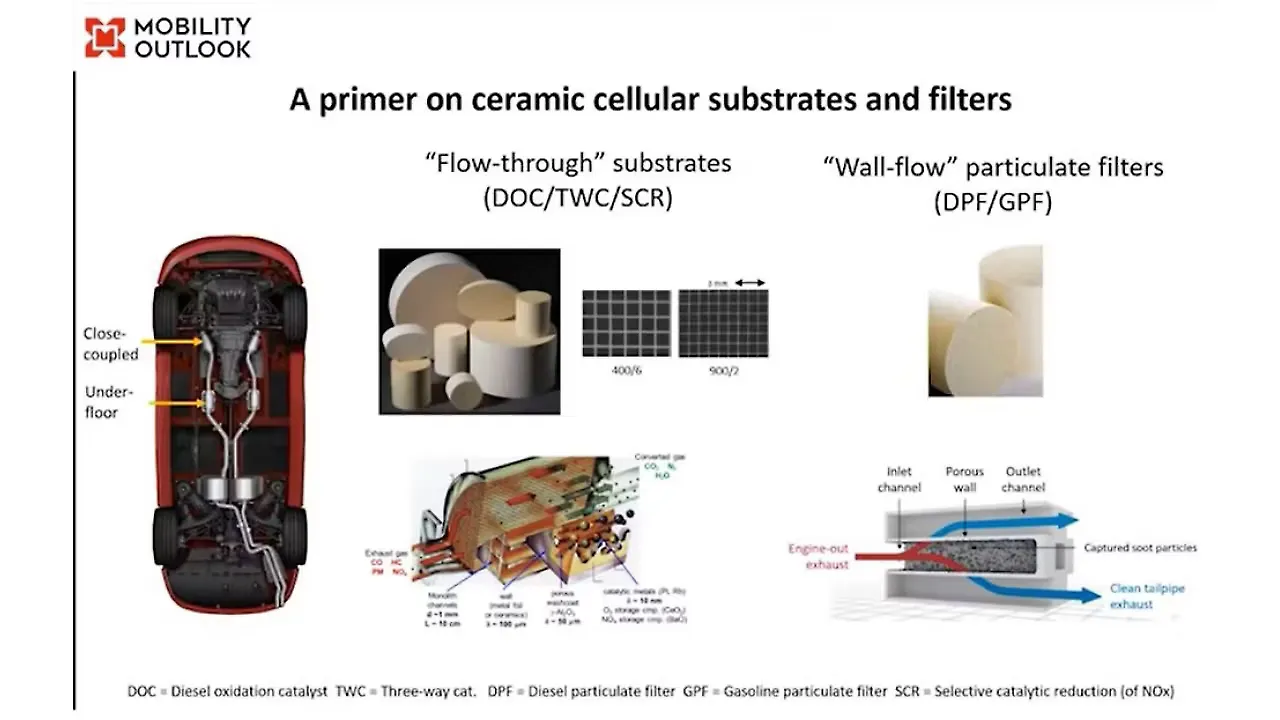

On the products that the company offers, he said, there are flow-through substrates (Diesel Oxidation Catalyst/ Three-way Cat/ Selective Catalytic Reduction) and wall-flow (Diesel Particulate Filter - DPF and Gasoline Particulate Filter- GPF) particulate filters. A lot of engineering goes into designing the micro-structure and actual size.

The main issue is managing the cold-start emissions as the emission is very high when the engine is cold as what is coming out after combustion goes out through the tail-pipe untreated. About 80% of the emissions are cold and untreated until the engine warms up.

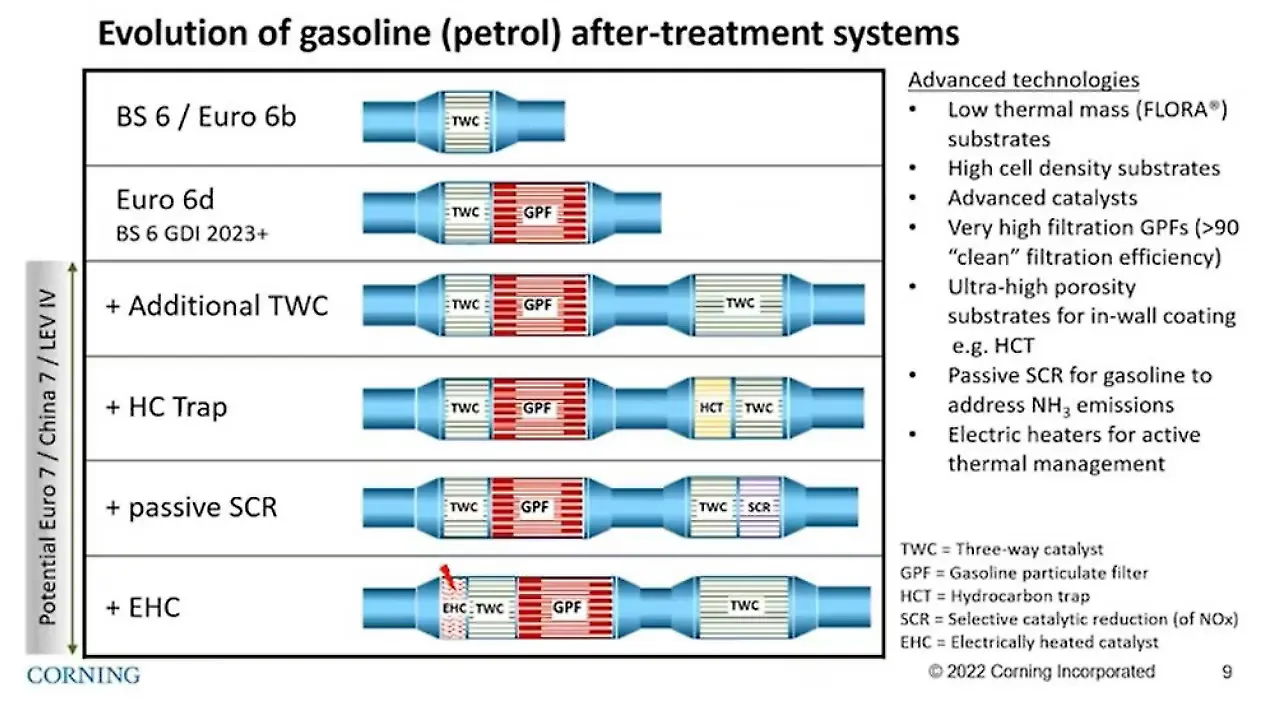

“We are trying to address cold-start emissions by adding additional hydrocarbon trap and three-way Cat in the close-coupled position,” he said.

Diesel Technologies For Gasoline

Passive SCR, which is traditionally used in diesel, is now used even in gasoline as ammonia limits are being introduced. As the industry is reaching to achieve zero tail-pipe emission, Dr Joshi suggested using an electrically heated catalyst. This additional thermal management will help, he opined.

He also touched upon certain advanced technologies, including low thermal mass (FLORA) substrates, high cell density substrates, advanced catalysts, very high filtration GPFs, ultra-high porosity substrates for in-wall coating and passive SCR for gasoline to address NH3 emissions.

“GPFs are incredibly efficient today and we are improving the efficiency further; we have started off with 70-80%, and as we hear from our customers, we are developing filters that are more than 90% efficient in the clean state i.e. without any soot,” he said.

All these initiatives have to happen without affecting the vehicle’s fuel economy, which is the challenge the OEMs are facing now.

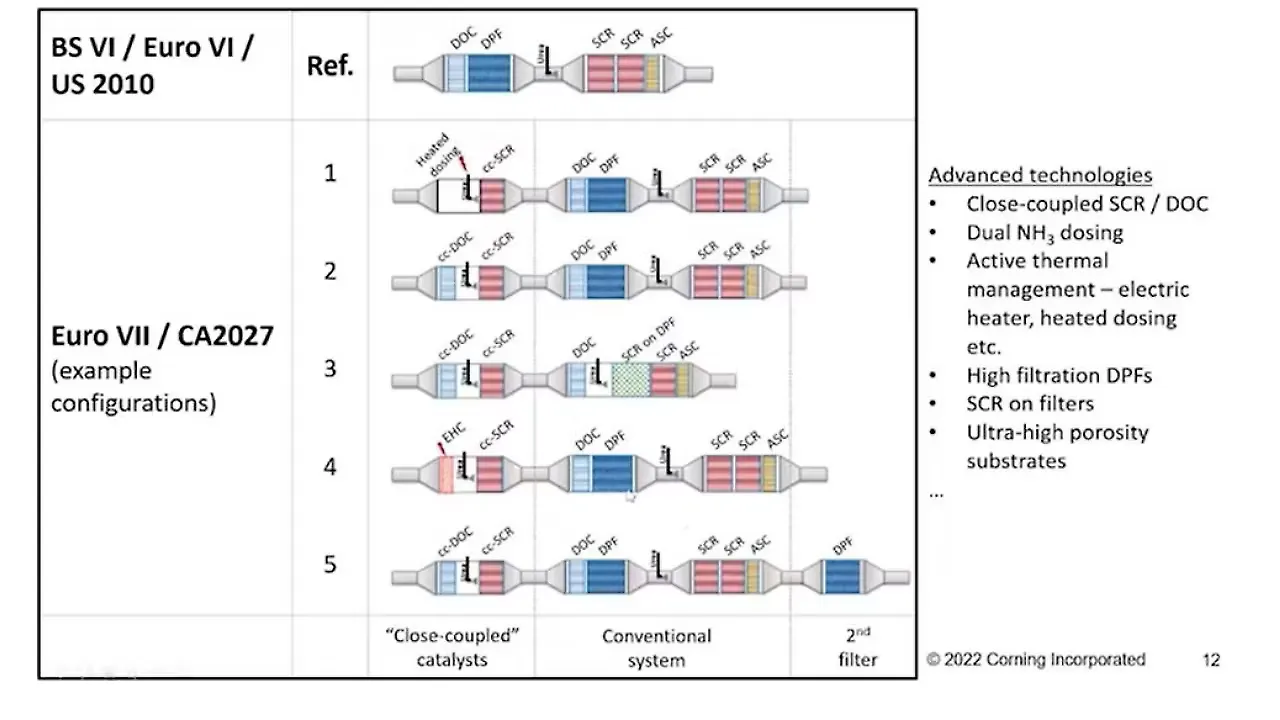

Talking on the heavy-duty diesel, he said the current technologies are DOC, DPF, SCR and ASC (ammonia slip catalyst), for achieving up to Euro-6. From now on, several advanced technologies are discussed, including close-couple SCR/DOC, dual NH3 dosing, active thermal management – electric heater, heated dosing, high-filtration DPFs, SCR on filters and ultra-high porosity substrates.

CNG is considered an essential technology for low NOX on the heavy-duty segment. Also, the hybrids' share in passenger cars is increasing owing to improved fuel efficiency.

Hybrids & Electric

BEVs and PHEVs are the more mature choice to lower emissions. However, policy decisions will play an essential role in how quickly these technologies are growing in their own market share. Regulations are being fine-tuned depending on the use case of the vehicle, he said.

Emissions From Unknown

With tail-pipe emissions going towards near zero, the non-tailpipe emissions from tyres and brakes will be the more significant portion of fleet emissions, even with vehicle electrification. “This will be the next wave of emissions that we will grapple with,” he said.

On the initiatives taken to mitigate non-tailpipe emissions, he said the tyre companies are working to reduce rolling resistance and tyre wear. For brakes, vacuum systems are being considered to be deployed near brake pads to suck the particles, ensuring that the emissions at the source are addressed. There is also work progressing in improving materials and systems.