Ashok Pandey, Director of Freudenberg Filtration Technologies India (FFTI), highlighted the Indian Government's significant emphasis on hydrogen, presenting ample opportunities for the company. In response to this strategic focus, FFTI has embarked on the development of fuel cell filters and air humidifiers, catering to applications in hydrogen internal combustion engines (H2 ICE) and fuel cells.

Both technologies require clean air and specific humidity levels to optimise performance. Currently, there are ongoing discussions within the commercial vehicle segment and stationary applications regarding the adoption of H2 ICE. These emerging trends open new business avenues for FFTI. Pandey also noted that Freudenberg has been supplying similar filters to several OEMs globally, further solidifying the company's expertise in this domain.

Addressing regulations, he noted that while emissions standards are in place, India currently lacks specific ordinances mandating cleanliness standards for cabin air. However, consumer demands are driving OEMs to consider offering higher-grade cabin air filters. These filters not only safeguard occupants but also protect interiors, instrument panels, and electronics. 'We prioritise educating customers and emphasise the technical benefits rather than solely focusing on cost. We have observed a shift in customer attitudes over the past five years, with many, who rejected us, now actively seeking out these advanced technologies,' he said.

Mitigating Market Volatility

Adapting to market fluctuations poses a significant challenge for businesses, especially during periods of domestic growth. However, with over 75 years of experience in the filtration industry, Freudenberg demonstrates resilience in swiftly responding to evolving circumstances. Strong internal supply chain management and efficient production planning enable the company to address market surges and meet customer demands effectively.

External factors such as geopolitical tensions, such as those between Ukraine and Russia, and recent incidents in the Red Sea, have disrupted regional trade and impacted supply chains. To mitigate these challenges, Freudenberg proactively builds inventory reserves. 'We prioritise timely deliveries, operating around the clock with most plants following Just-in-Time practices. Maintaining a delivery rating of no less than 98% with every customer is a key commitment,' he emphasised.

While managing outward supply chains through inventory management is feasible, inward supply chain management presents its own set of challenges. However, as a backward-integrated company, FFTI effectively navigates these challenges. Freudenberg’s Performance Materials division supplies the majority of filter manufacturing materials internally, ensuring continuity of supply. 'Nearly 70% of our materials come from within the group, supplemented by robust agreements, forecasting, and proactive meetings to address potential issues,' explained the spokesperson. In the face of disruptions, the company leverages its global presence to diversify sourcing, tapping into alternative locations such as Taiwan, China, and Japan, as well as the United States, Korea, and Thailand. This strategic approach, coupled with Freudenberg's global network, reinforces the company's resilience amidst market volatility.

Transitioning From Mass Production To Mass Customisation

Similar to the consumer durable industry, the automotive sector is embracing a shift from mass production to mass customisation. 'One advantage in the automotive industry is the consistency of certain components, which allows for standardisation. For example, while a vehicle may offer over 20 variants, the components we supply to OEMs are often limited to a maximum of five variations. Although there are minor adjustments, overall standardisation remains,' he explained. This approach aligns with the company's utilisation of flexible production lines, enabling efficient adaptation to varying customer needs and specifications.

Addressing Environmental Concerns

Pandey highlighted Freudenberg's commitment to sustainability, revealing that the company incorporates recycled fibers, accounting for a minimum of 20% to 25% in its filter manufacturing. Furthermore, the Indian arm is aligning its efforts with headquarters to reduce CO2 emissions by 25% by 2026 and 40% by 2030. In line with this goal, FFTI has enhanced its Pune plant's capacity and optimised material flow to accommodate its growth rate of over 25% CAGR. Currently producing 75 stock keeping units (SKUs), the company anticipates this number to surpass 300 within the next five years, necessitating a 10% increase in manpower. Additionally, the company is automating many manual processes to streamline operations and enhance efficiency, all while ensuring uninterrupted supply to customers.

Moreover, Freudenberg is exploring alternative materials, particularly natural fibers, for filtration products. For instance, activated charcoal's unique voluminous and porous structure makes it ideal for surface binding, or adsorption, effectively capturing toxins and chemical molecules. Activated charcoal also excels in filtering odours from various gases, including acidic ones, making it essential for eliminating noxious gases and ensuring clean air quality.

Automated Filtration

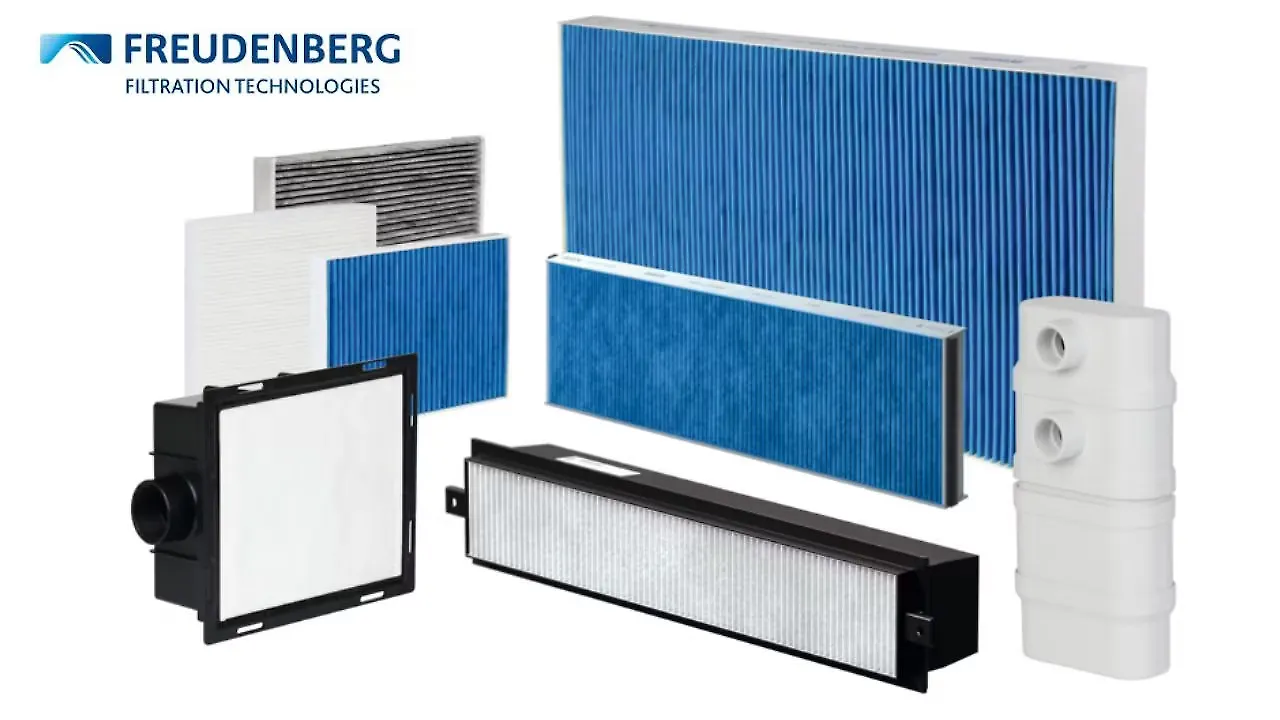

When asked about the potential for automatic atmospheric sensing and filtration management, Pandey affirmed the possibility, citing the integration of multilayer filtration systems with Artificial Intelligence. These systems comprise multiple layers: a primary particle filter, followed by activated carbon, and finally, a HEPA (high-efficiency particulate air) filter. Pandey emphasised that these layers don't necessarily operate simultaneously; instead, they adjust based on atmospheric conditions detected by sensors. Controlled by both hardware and software, the filtration system's responsiveness is key. While such advanced systems are under development, their success will hinge on their economic feasibility for vehicle integration.

Currently, Freudenberg is focused on developing multi-stage or multilayered filtration systems. These systems have been proposed to select clients, offering drivers the ability to activate additional filtration layers when atmospheric air quality deteriorates. This feature allows drivers to enhance air filtration by simply activating a switch, ensuring cleaner air within the vehicle cabin.

Also Read:

Esther Maria Loidl, CHRO, Freudenberg SE | Mobility Outlook | Women In Mobility