The article has been authored by Mike Kultgen, Greg Zimmer and Stefan Janhunen.

The use of large-scale battery arrays for backup and carry-through energy storage is getting increasing attention, as evidenced by Tesla Motors’ recent announcement of their Powerwall system for homes and offices. The batteries in these systems are continually charged from the power-line grid or other source, and then deliver AC-line power back to the user via a DC/AC inverter.

Using batteries for power backup is not new, with many systems spanning basic 120/240 VAC and several hundred watts for short-term desktop-PC backup, to thousands of watts for specialty vehicles, such as ships, hybrid cars, or all-electric vehicles, up to hundreds of kilowatts for grid-scale telecom and data-centre backup (Figure 1).

Yet, while advances in battery chemistry and technology get much of the attention, an equally critical part of a viable battery-based installation is its battery management system (BMS).

Meeting Stringent Regulatory Standards

There are many challenges when implementing BMS for energy storage, and their solutions do not simply scale up from small-scale, lower-capacity battery packs. Instead, new and more sophisticated strategies and critical support components are needed.

The challenge begins with the need for high accuracy and confidence in the many measurements of key battery cell parameters. Further, the design must be modular in its sub-systems to enable tailoring the configuration to the specific needs of the application, along with possible expansion, overall management issues, and necessary maintenance.

The operating environment of larger-scale storage arrays brings other significant challenges as well. The BMS must provide precise, consistent data within an extremely noisy electrical and often hot environment despite the high voltage/ current inverters and resultant current spikes. In addition, it must provide extensive fine-grain data on internal module and system temperature measurements, which are critical for charging, monitoring, and discharging, rather than just a few broad-brush aggregate values.

Due to the basic role of these power systems, their operating reliability is inherently critical. To translate that easily stated objective into reality, the BMS must ensure data accuracy and integrity, along with continuous health assessments so it can take the needed actions on an ongoing basis.

Achieving a robust design and safety is a multi-level process, and the BMS must anticipate problems, perform self-test, and provide failure detection on all sub-systems, then implement appropriate actions while in standby and operational modes. As a final mandate, due to the high voltage, current, and power levels, there are many stringent regulatory standards that the BMS must meet.

System Design Translates Concepts To Real-World Results

Although monitoring rechargeable batteries is simple in concept – just place the voltage- and current-measurement circuits at the cell terminals – the reality of a BMS is quite different and much more complicated.

Robust design begins with comprehensive monitoring of individual battery cells, which places significant demands on analogue functions. The cell readings need millivolt and milliamp accuracy, and voltage and current measurements must be time-synchronised to calculate power.

The BMS must also assess validity of each measurement, as it needs to maximise data integrity, while it must also identify errors or questionable readings. It cannot ignore unusual readings, which may indicate a potential problem, but at the same time, it should not take action based on data that has errors.

A modular BMS architecture enhances robustness, scalability, and reliability. Modularity also facilitates use of isolation where needed in the data links between sub-sections to minimise impact of electrical noise and to enhance safety. In addition, advanced data-encoding formats, including CRC (cyclic redundancy check) error detection and link acknowledgement protocols assure data integrity, so the system management function has confidence that the data it receives is what was sent.

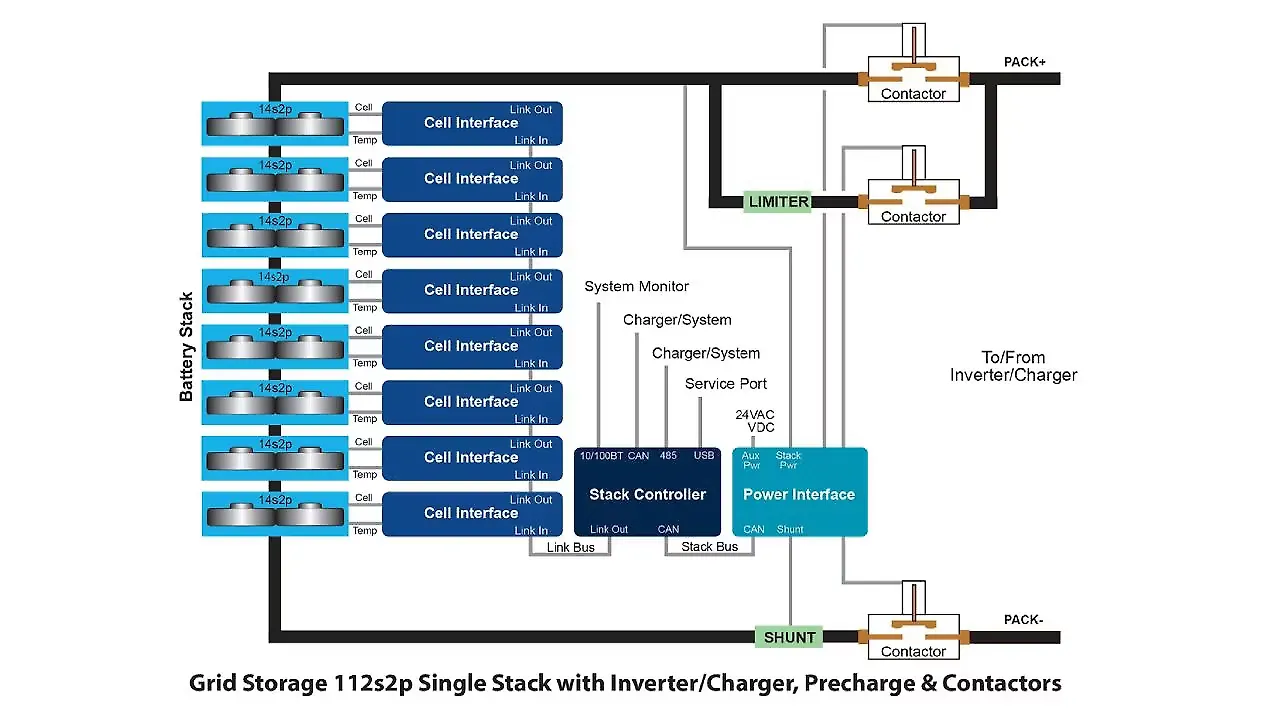

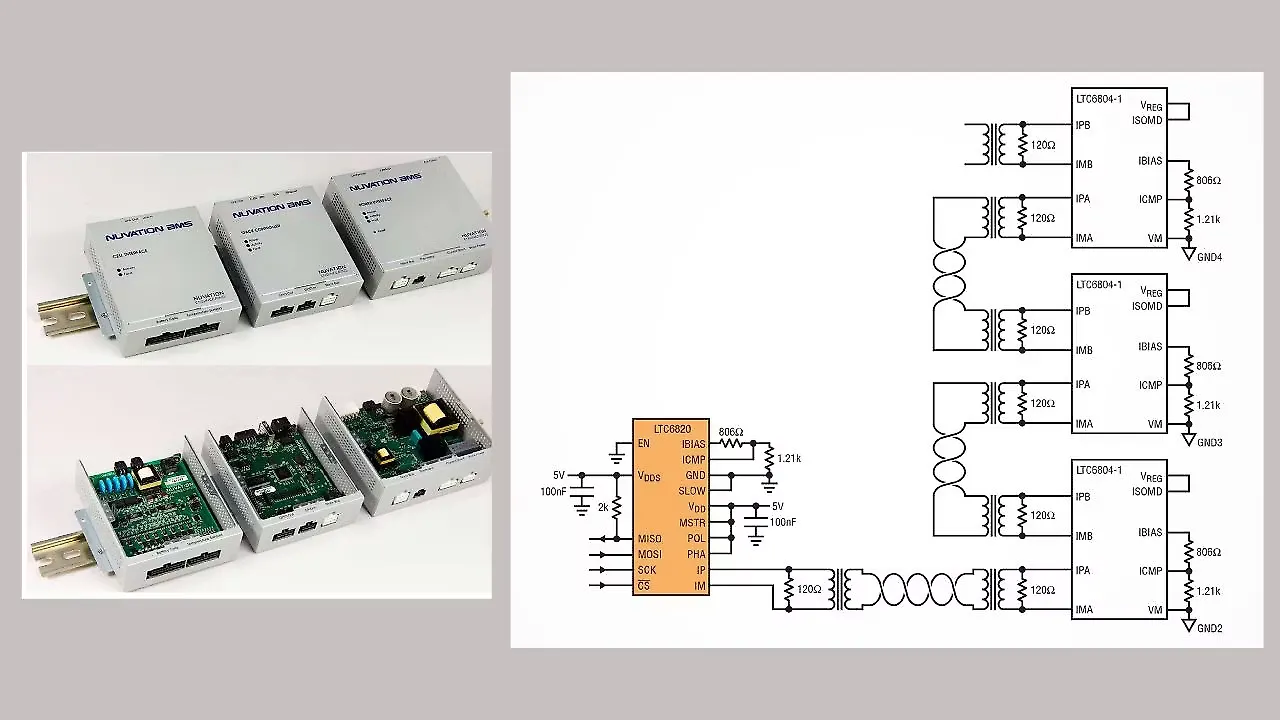

An example of a BMS that incorporates these principles is the scalable and customisable BMS developed by Nuvation Engineering (Waterloo, Ontario and Sunnyvale, CA). The Nuvation BMS design is proving itself with design wins in grid energy-storage systems and power-backup equipment, where reliability and ruggedness are critical. The key advantage of this off-the-shelf BMS is its tiered, hierarchical topology (Figure 2) with three sub-systems, each with unique functions, as shown in Figure 3.

- The cell interface provides tight management and monitoring of each battery cell in a stack; the system uses as many cell interfaces as needed, depending on the number of stacks. These interfaces can be daisy-chained as the number of cells and thus the stack voltage increases.

- The cell interface is connected to a single stack controller, which monitors and manages multiple cell-interface units. Multiple stack controllers can be connected together, if needed, to support large packs with many stacks in parallel.

- The power interface connects the stack controllers to high voltage/ current lines and is the interface to the inverter/ charger. It isolates high-voltage and high-current components of the stack physically and electrically from the other modules. It also powers the BMS directly from the battery stack, thus eliminating the need for any external power supplies for the BMS operation.

The modular and hierarchical architecture of the Nuvation BMS supports battery-pack voltages ranging up to 1,250 VDC, using cell-interface modules, each containing up to 16 cells, stacks with up to 48 cell-interface modules, and battery packs that contain multiple stacks in parallel. The entire array assembly is managed as a single unit from the user’s perspective.

Solid Design Builds From The Bottom Up

Factors such as modular architecture, hierarchical topology, and error-aware design are essential to the integrity and expandability of the Nuvation BMS, but not enough. A successful implementation requires high-performance functional blocks to serve as the physical foundation.

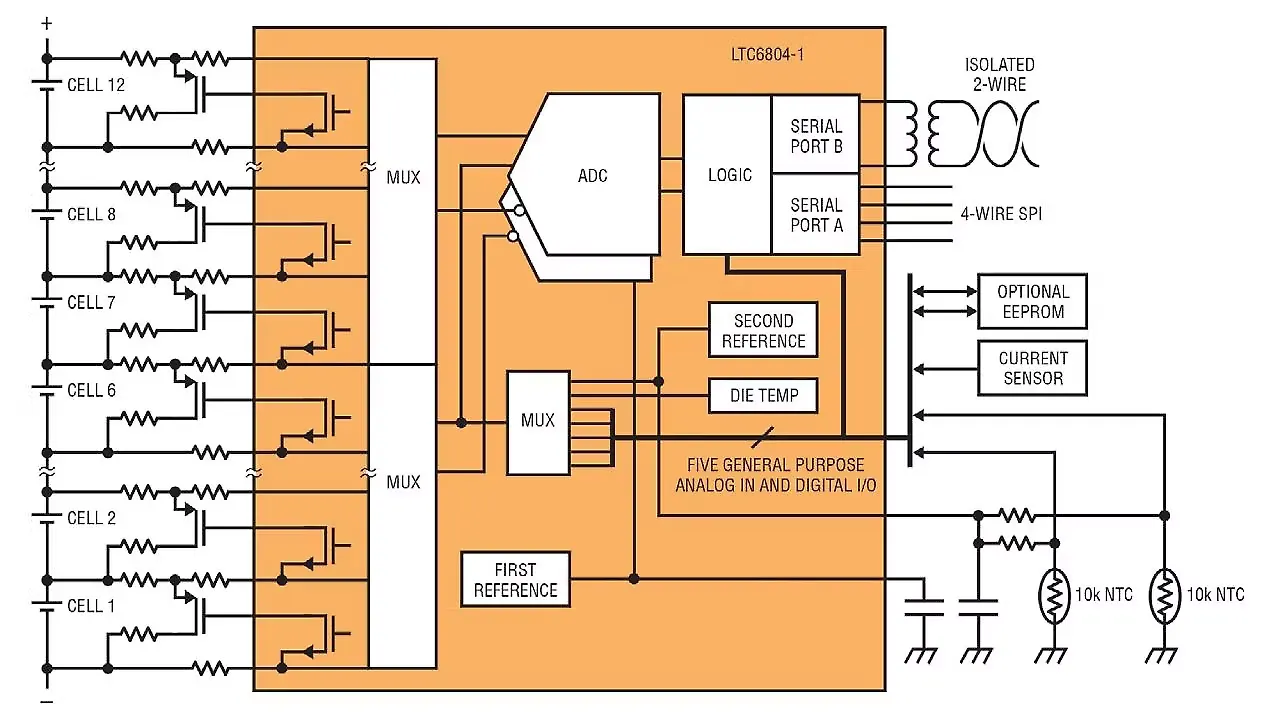

That’s why the LTC6804 Multicell Battery Monitor IC from Linear Technology (Figure 4) plays a critical role in the Nuvation BMS implementation [1]. It is expressly tailored for the needs of BMS systems and multicell designs, beginning with providing precise measurements of up to 12 battery cells stacked in series.

Its measurement inputs are not ground-referenced, which greatly simplifies measurement of those cells, and the LTC6804 itself is stackable for use with higher-voltage arrays (and it also supports a variety of cell chemistries). It offers maximum 0.033% error with 16-bit resolution, and needs just 290 μs to measure all 12 cells in the stack. Such synchronised voltage and current measurements are critical to yield meaningful analysis of power parameters.

Of course, performance in the benign environment of a prototype at the bench is not the same as actual achievable performance in an electrically and environmentally hostile real-world BMS setting. The LTC6804’s analogue/ digital converter (ADC) architecture is designed to resist and minimise those detrimental effects, using filters specifically designed for the noise of power inverters.

The data interface uses a single twisted-pair, isolated SPI interface which supports rates up to 1 Mb and distances of up to 100 m. To further enhance system integrity, the IC includes an array of ongoing sub-system tests. As further indication of its reliability and ruggedness, the LTC6804 meets the stringent AEC-Q100 standard for automotive quality.

This IC achieves its results due to an application-specific design which focuses closely on BMS issues and environments, including the unique system-level objectives of the application and its many challenges.

Three Major Issues Resolved

The LTC6804 addresses three major areas that affect system performance, conversion accuracy, cell balancing, and connectivity/ data-integrity considerations:

1. Conversion Accuracy

Due to the short- and long-term accuracy demands of the BMS application, it uses a buried-Zener conversion reference rather than a bandgap reference. This provides a stable, low-drift (20 ppm/√kHr), low-temperature coefficient (3 ppm/°C), low-hysteresis (20 ppm) primary voltage reference along with excellent long-term stability.

This accuracy and stability is critical since it is the basis for all subsequent battery-cell measurements and these errors have a cumulative impact on acquired-data credibility, algorithm consistency, and system performance.

Although a high-accuracy reference is a necessary feature to ensure superior performance, that alone is not enough. The A/D converter architecture and its operation must meet specifications in an electrically noisy environment, which is the result of the pulse-width modulated (PWM) transients of the system’s high current/ voltage inverter. Accurate assessment of the state of charge (SOC) and health of the batteries also requires correlated voltage, current, and temperature measurements.

To mitigate the system noise before it can affect the BMS performance, the LTC6804 converter uses a delta-sigma topology, aided by six user selectable filter options to address noisy environments. The delta-sigma approach reduces the effect of electromagnetic interference (EMI) and other transient noise, by its very nature of using many samples per conversion, with an averaging, filtering function.

2. Cell Balancing

The need for cell balancing is an unavoidable consequence in any system that uses large battery packs arranged as groups of cells or modules. Although most lithium cells are well matched when first acquired, they lose capacity as they age. The aging process can differ from cell to cell due to a number of factors, such as gradients in pack temperature.

Exacerbating the whole process, a cell that is allowed to operate beyond its SOC limits will prematurely age and lose additional capacity. These differences in capacity, combined with small differences in self-discharge and load currents, lead to cell imbalance.

To remedy the cell imbalance issue, the LTC6804 directly supports passive balancing (with a user-settable timer). Passive balancing is a low cost, simple method to normalise the SOC for all cells during the battery charge cycle. By removing charge from the lower capacity cells, passive balancing ensures these lower capacity cells are not overcharged. The LTC6804 can also be used to control active balancing [2], a more complicated balancing technique which transfers charge between cells through the charge or discharge cycle.

Whether done using active or passive approaches, cell balancing relies on high measurement accuracy. As measurement error increases, the operating guard band, which the system establishes must also be increased, and therefore the effectiveness of the balancing performance will be limited. Further, as the SOC range is further restricted, the sensitivity to these errors also increases. The LTC6804’s total measurement error of less than 1.2 mV is well within system-level requirements.

3. Connectivity/ Data Integrity Considerations

Modularity in the battery-pack design adds to scalability, serviceability, and form-factor flexibility. However, this modularity requires that the data bus between packs has galvanic isolation (no ohmic path), so failures in any one pack do not affect the rest of the system or put high voltages on the bus. Further, the wiring between packs must tolerate high levels of EMI.

A two-wire isolated data bus is a viable solution to achieve these goals in a compact and cost-effective way. Therefore, the LTC6804 offers an isolated SPI interconnect called iso-SPI, which encodes the signals for clock, data in, data out, and chip select into differential pulses, which are then coupled through a transformer, a rugged, reliable, and long established isolation component (Figure 5).

Devices on the bus can be connected in a daisy chain configuration, which greatly reduces harness size and enables modular designs for large, high-voltage battery packs, while maintaining high data rates and low EMI susceptibility (Figure 6).

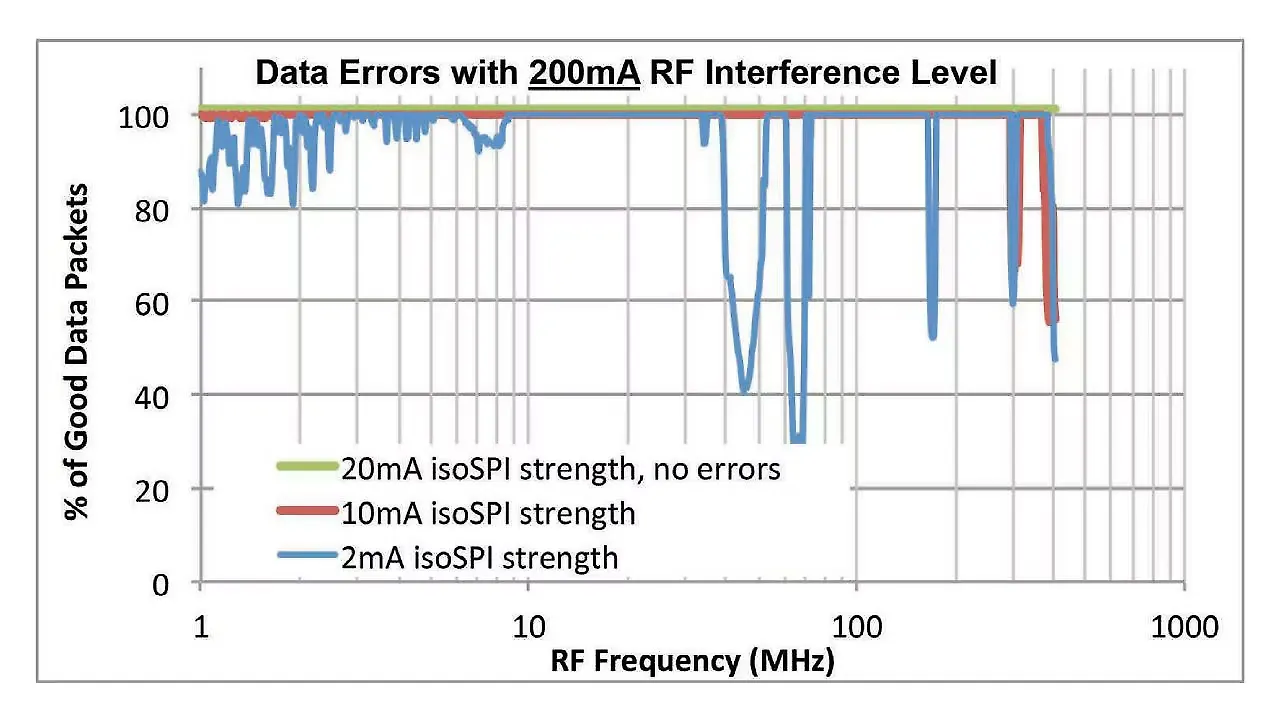

To demonstrate the noise immunity, Linear Technology performed BCI testing on the LTC6804. This involved coupling 100 mA of RF energy into the battery-wiring harness, with the RF carrier swept from 1 MHz to 400 MHz and with 1 kHz AM modulation on the carrier. The LTC6804 digital filter was programmed for a 1.7 kHz cut-off frequency, and an external RC filter and ferrite choke were added as well.

The result: the error in voltage reading was below 2 mV over the entire RF sweep range. An array of self-assessment and self-test features adds to the suitability of the LTC6804 for BMS applications. These checks include open-wire detection; a second internal reference for ADC clock; multiplexer self-test, and even measurement of its internal power supply voltages. The device is engineered for systems that are intended to be compliant with ISO 26262 and IEC 61508 standards.

Conclusion

There’s a lot of glamour associated with backup and carry-through supplies for grid-level systems. It seems so straightforward – just keep an array of batteries charged (whether from the grid-AC line, or solar, wind, or other renewable sources), then use the batteries with a DC/AC inverter when you need to provide line-equivalent AC power.

The reality is that batteries are not simple in any of their behaviour or performance characteristics, and they need carefully-controlled charging, monitoring of their voltage, current, and temperature, and discharging. As power levels increase, a practical, efficient, and safe system is not a trivial design, and so a grid-connected multicell BMS is a complex system. Many unique problems need to be understood and addressed, with safety a major concern as well.

A successful and viable system design needs a modular, structured, top-down architecture that is supported from bottom up by optimised components such as the LTC6804. When combined with sophisticated, secure data-acquisition and control software, the result is a high-performance, reliable BMS that requires minimal operator involvement, and will function autonomously for years of reliable service.

References:

[1] https://www.analog.com/en/products/ltc6804-1.html

[2] https://www.analog.com/en/product-category/battery-cell-balancers.html

About the Authors: Mike Kultgen is Fellow and GM of the Automotive BMS Group at Analog Devices; Greg Zimmer is Senior Product Marketing Engineer, Signal Conditioning Products at Linear Technology Corporation, Analog Devices and Stefan Janhunen is Design Engineer, BMS Products at Nuvation Engineering.

Also Read: