Dimethyl carbonate (DMC) is an oxygenated fuel with a high oxygen content of 53.28%. It is a colourless, flammable liquid with the formula OC(OCH3)2. DMC is a carbonate ester that can be used as a co-solvent in lithium-ion batteries and as a methylating agent.

Production of DMC

DMC is primarily produced through the chemical synthesis of methanol and phosgene. This reaction yields DMC as the main product, along with other by-products. Alternative methods of DMC production are being explored to improve efficiency and reduce environmental impact.

DMC is a promising additive for diesel fuel. Blending DMC with diesel can reduce the diameter of primary soot particles by 37%. The oxygen content in the fuel can also suppress soot formation, support soot oxidation, and reduce particle emissions.

Advantages:

- Environmentally Friendly - Non-toxic and biodegradable

- Low Volatility - Advantageous in applications where low evaporative emissions are crucial

- High Solvency Power - Effective solvent for a wide range of polar and non-polar substances

- Reactivity - Versatility in the synthesis of pharmaceuticals, agrochemicals, and speciality chemicals

- Biodegradability - Reduces the risk of long-term environmental impact

- High Octane Rating - Improves combustion efficiency and potentially enhance engine performance

- Potential Renewable Feedstock - Produced from renewable resources, such as biomass-derived methanol

- Reduced Carbon Footprint: Can reduce overall carbon footprint due to its lower emissions during combustion

Limitations:

- Limited Availability - Establishing a robust supply chain and production infrastructure is crucial

- Cost Considerations - The production and purification processes for DMC can be relatively expensive.

- Low Energy Density - Lower energy density compared to conventional hydrocarbon-based fuels

- Material Compatibility Issues - Corrosion or degradation of engine and fuel system components can occur, necessitating modifications or alternative materials

- Hygroscopic Nature - Tends to absorb moisture, which can lead to issues such as phase separation and reduced stability in certain formulations

- Health and Safety Concerns - Exposure to high concentrations or prolonged exposure may still pose risks

- Ignitability - Has a low flash point, which means it can ignite at relatively low temperatures, posing safety challenges during handling, storage, and transportation, requiring appropriate safety measures.

DMC as a potential fuel for Automobiles

- Integrating DMC into engine applications may necessitate modifications to the fuel injection system and combustion parameters. Adjustments in the engine control unit (ECU) settings, such as fuel-air mixture ratios and ignition timing, may be needed to optimize performance with DMC.

- The compatibility of engine materials with DMC should be considered, and certain components may need to be upgraded to prevent corrosion or degradation.

- The energy density is lower than that of conventional hydrocarbon-based fuels, leading to lower engine power and efficiency.

- The high-octane rating of DMC can potentially improve the efficiency of the combustion process, leading to reduced engine knock and enhanced thermal efficiency.

- DMC produces lower CO2 and NOx emissions compared to traditional hydrocarbon-based fuels.

ARAI’s experience on DMC as an Automotive Fuel

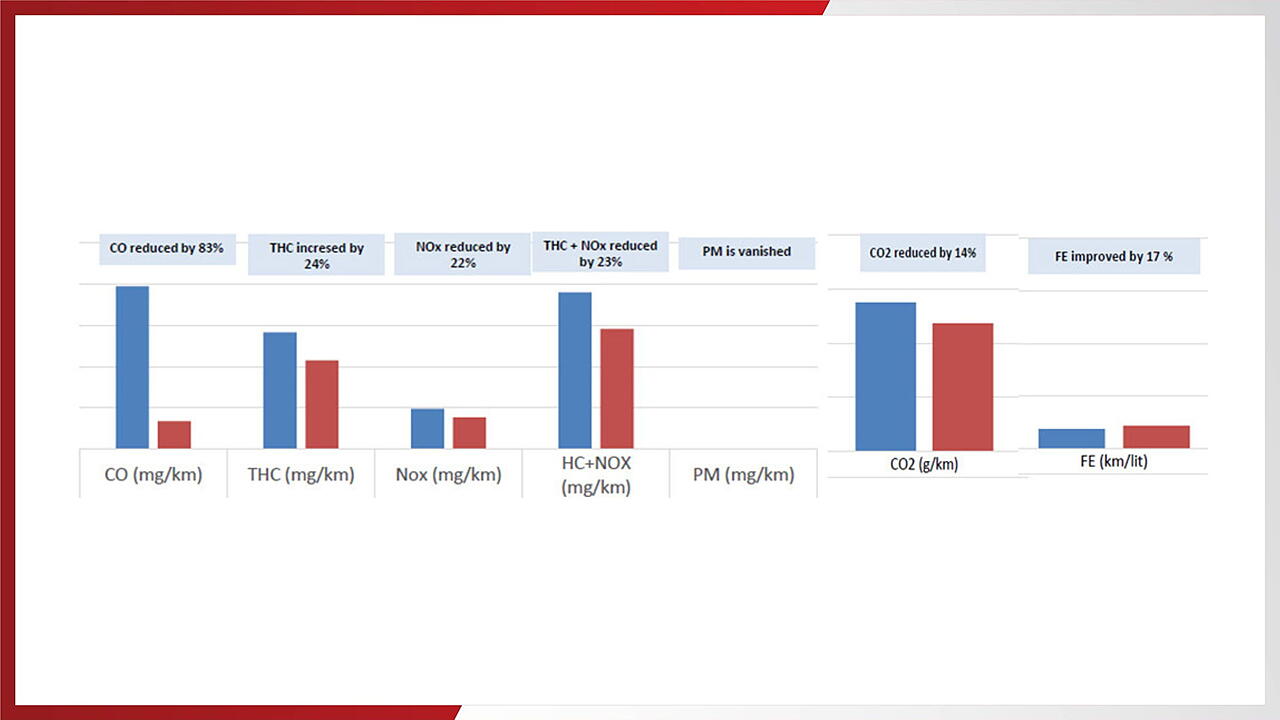

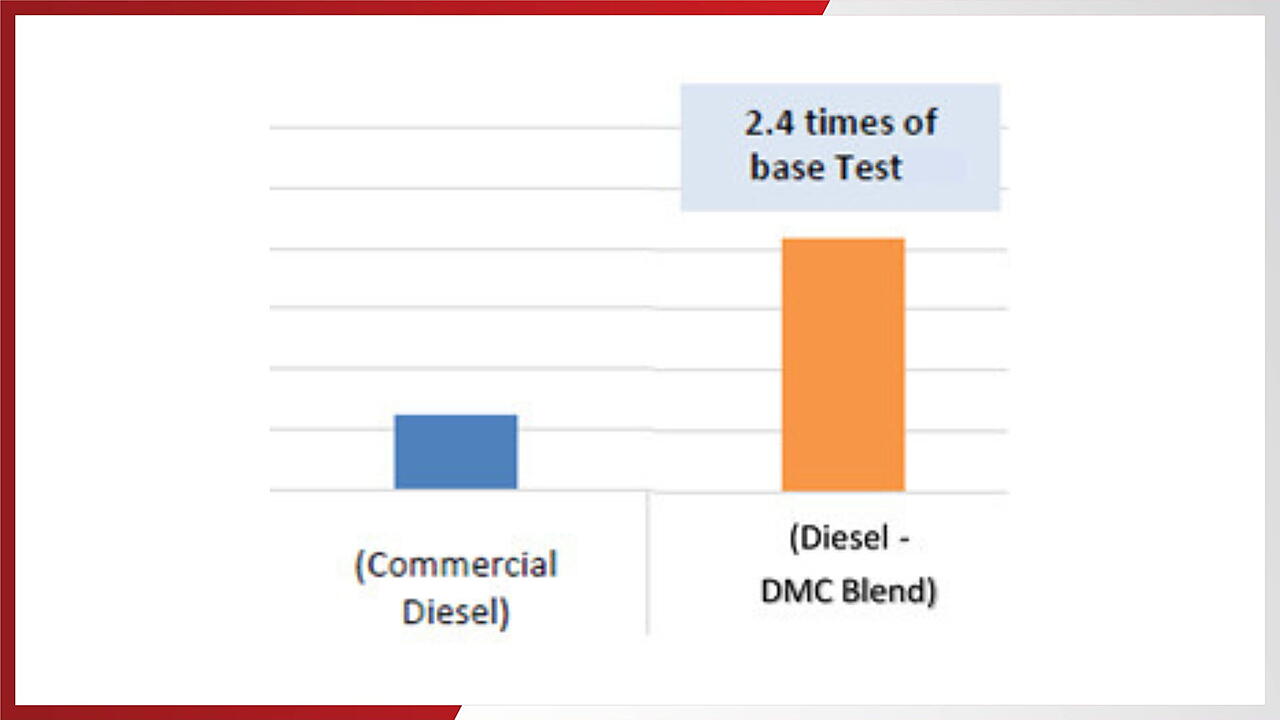

ARAI had conducted a Vehicle emission performance evaluation of Diesel-DMC blends on a chassis dynamometer. In this evaluation, an in-use diesel vehicle was tested on a chassis dynamometer for Diesel-DMC fuel blends. The regulated and unregulated emissions and fuel economy were compared with commercial diesel fuel. The vehicle was not calibrated for the diesel-DMC fuel blend, and the tests were repeated back-to-back after testing the vehicle on commercial diesel fuel. The comparative results are shown below.

Figure 1: Regulated emissions and Fuel Economy comparison for Diesel-DMC fuel blend

Figure 2: Unregulated Emissions comparison for Diesel-DMC fuel Blend

As compared to commercial diesel fuel, the CO, NOx and HC+NOx emissions were reduced by 83%, 22% and 23%, respectively, whereas the THC emissions increased by 24%. PM emissions are not visible on the particulate filter and are untraceable. The CO2 emissions are reduced by 14%, whereas the fuel economy is improved by 17%. However, the unregulated emissions are increased by 2.4 times as compared to commercial diesel and are measured in micrograms/test.

Conclusion: DMC shows promise as a potential fuel for automobiles, with its lower emissions and improved fuel efficiency. However, high production costs and limited availability, along with safety concerns and regulatory considerations, pose challenges that need to be addressed for DMC to become a mainstream fuel option. Continued research and development efforts are crucial for the future prospects of DMC fuel technology.

Also Read

Global Hydrogen Fuel Cells Market To Grow At 41.1% CAGR Till 2027