An estimated 23.8 million tonne of lithium-ion batteries will be recycled between 2023 and 2043, since these batteries dominate the electric vehicles (EV), consumer electronics and stationary energy storage markets, the latest report from IDTechEx noted. However, the sustainability of these batteries through their entire lifecycle must be managed, including at End-of-Life (EOL).

IDTechEx's new report, 'Li-ion Battery Recycling Market 2023-2043,' noted several factors that will drive recycling market growth, helping to maximise the utilisation of increasing feedstock availability.

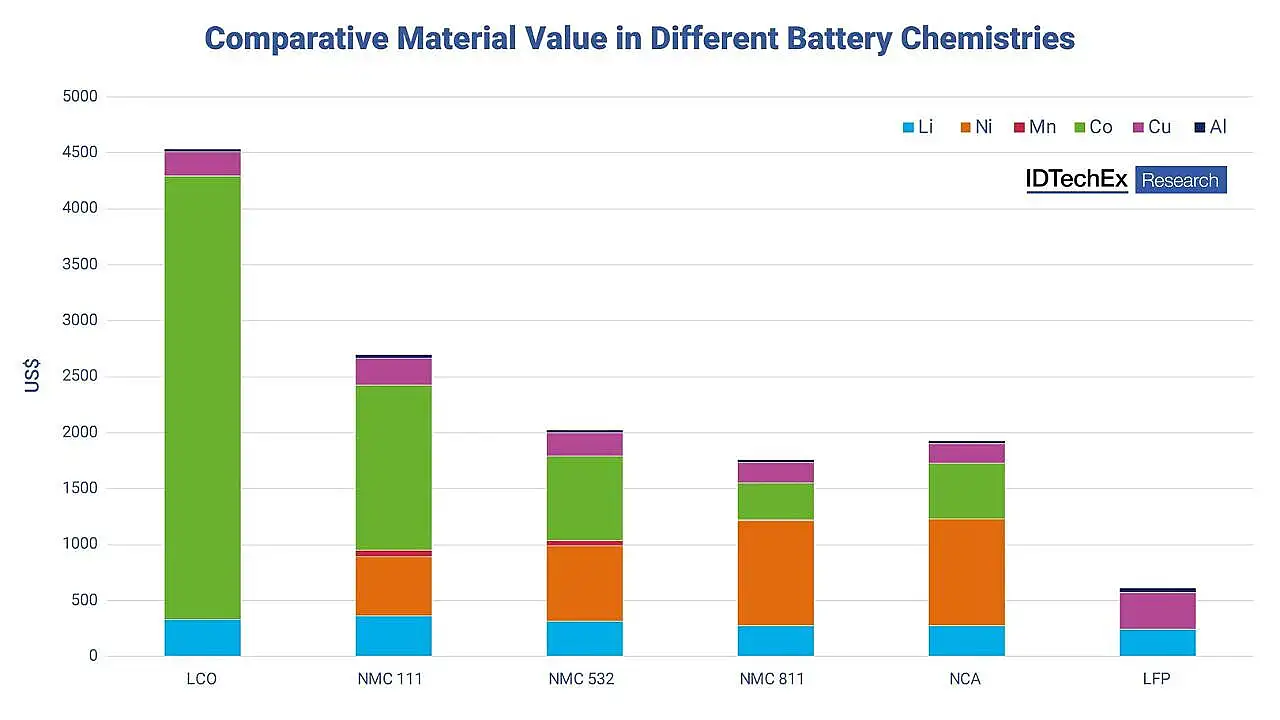

Fears over supply bottlenecks to lithium, nickel, and cobalt in the medium term provide an opportunity for recycling. Recycling Li-ion batteries allows such valuable raw materials to be obtained and re-introduced into new battery manufacturing. This can help to provide a more secure, diversified, and local supply of raw materials and reduce reliance on mining for virgin materials, bringing environmental benefits.

According to the report, key regions such as the US and Europe want to expand their recycling capacities to domesticate critical material supply. However, these regions mostly focus on producing black mass from mechanical recycling techniques, requiring further refining into metal salts, which can then be further processed into new cathode precursor material. Few companies in these regions, including Fortum in Europe, have established commercial-scale hydrometallurgical recycling plants to produce metal salts. Therefore, a substantial domestic supply of usable intermediary products to be used in new battery manufacturing in these regions is still some years away, the report said.

Policies On Recycling Batteries

IDTechEx observed that while China has some of the most comprehensive policies regarding battery end-of-life management, other regions, such as the EU and India, have introduced policies that will drive battery recycling. The EU Battery Regulation, soon coming into force, specifies collection rate targets for EV batteries and targets for overall recycling efficiency, specific material recovery efficiency and minimum recycled contents in new batteries. Some of these targets are initially set for 2025, with others specified from 2028 or later and will increase over time. India's 'Battery Waste Management Rules 2022' also specify similar targets.

Extended producer responsibility (EPR) will force OEMs to be responsible for financing the collection of EVs that have reached EOL, which will help in meeting collection rate targets for recycling. In the US, the introduction of Advanced Manufacturing Production Credits (PTC) through the Inflation Reduction Act (IRA) provides an incentive for EV battery manufacturers to receive tax credits if a minimum percentage, by value, of critical minerals sourced from recycling in North America is used in new EV batteries. This should start to drive the use of recycled materials in new EV batteries sourced domestically in the US in the coming years, the research company noted.

Capturing Embedded Value

The majority of consumer devices currently use lithium-cobalt-oxide (LCO) batteries. The intrinsic value of these batteries is higher than those used in EV batteries or stationary energy storage due to the higher volume of cobalt in LCO batteries. Therefore, recycling LCO batteries could be profitable; however, establishing the infrastructure for collecting electronic consumer devices is far more challenging than for EV and industrial batteries. As a growing number of EV batteries will adopt high-nickel batteries, these will contain low cobalt content, reducing the embedded value which can be captured. However, processes are continuing to be developed by companies that aim to extract as much material from Li-ion batteries as possible.

Courtesy: IDTechEx.

Also Read:

Stellantis Invests In Lyten’s Lithium-sulfur EV Battery Technology