In a bid to provide the necessary link between the user and the data source, manage data transfer, analysis, generate reports automatically on server, and eventually reduce the product development time, the New Delhi-headquartered Automotive Test Systems (ATS) has introduced a Remote Data Acquisition & Management (RDAS).

Using the RDAS system, the customers can access data from multiple vehicles at ease, with almost no delay, even when the network connection is unreliable.

According to ATS, which is involved in a host of services including product validation, structural testing, data acquisition and analysis, vehicle handling & performance evaluation, NVH and powertrain testing, RDAS will help automate data transfer from data acquisition system to cloud/server with no delay.

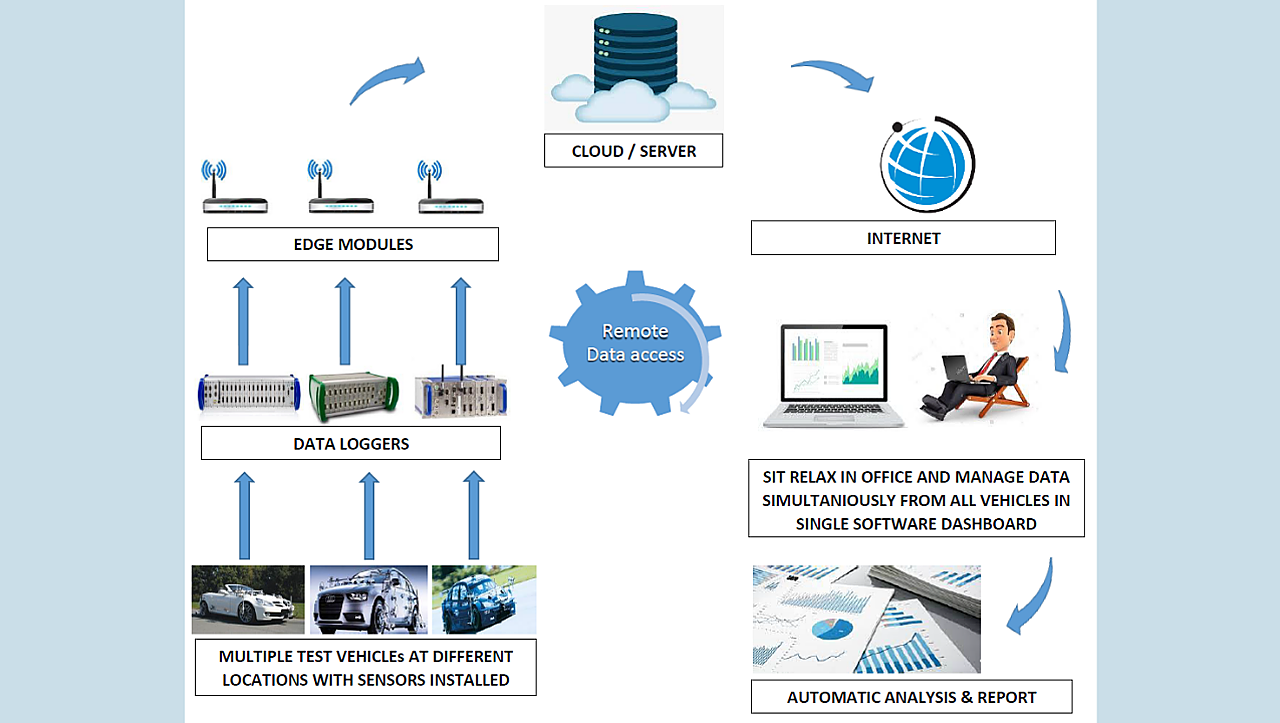

RDAS works with multiple data acquisition (DAQs) connected via a local area network such as Ethernet or Wifi, to one or more Edge Gateways, which are in turn securely connected to a public or private cloud system over the internet or intranet. Using the company’s own web application, which runs on the cloud, data can be accessed using any standard browser from laptops or computers. The web application provides the status, configuration, site details and station view for overall monitoring and storage.

Speaking to Mobility Outlook, S Ramanathan, Managing Director, ATS, said typically a large number of vehicles undergo testing at the OEM’s track, their development partners’ facility and also at various other test tracks.

One of the main advantages of RDAS is that the technology will help reduce high level manpower visiting tracks in remote parts. As a result it will avoid skilled manpower on the track to analyse the data and send them to their higher-ups back at the R&D centre to take decisions.

“Now they can have their entire team of experts sitting in their engineering office having access to the test data in real time, sending across their comments and decisions to their test drivers, saving a lot of time and money,” he said.

RDAS claims to offer data access from multiple vehicles even with an unreliable network. Explaining the nuances, Ramanathan said when there is network interruption of any type during measurement time, DAQ saves the data in buffer storage and transfers the data once the link comes up.

To mitigate issues relating to cyber security, the system banks on Edge Gateway, which has certificate based authentication. “Only traffic coming from our gateways will be accepted at the server. All the traffic going from our Edge Gateway is sent via a secure tunnel which is encrypted,” Ramanathan said.

Elaborating on the support offered by RDAS to the users, he said the system can be used in variety of application as an add-on to automotive R&D application, where wired communication is not feasible and range of wireless transmission is less like automotive fleet testing, long duration road trials, climatic chambers, elevator testing, rail testing, etc.

It will help the user reduce the data collection, and management time as it can be accessed in real time.

Furthermore, it can be automated for processing and analysis, eventually reducing the development time by up to 15%, which is a huge advantage for all OEM and Tier-I companies, he added.