In the wake of the global chip shortage, Bosch has further extended its commitment to produce wafer fabs with a fresh investment announcement of € 400 mn in its chip manufacturing facilities in 2022. The company would expand production in Dresden and Reutlingen in Germany, and its semiconductor operations in Penang, Malaysia.

Dr Volkmar Denner, Chairman of the board of management, Robert Bosch GmbH said Bosch is systematically expanding its semiconductor production so it can provide its customers with the best possible support.

Most of the capital expenditure is earmarked for Bosch’s new 300 mm wafer fab in Dresden, where manufacturing capacity is to be expanded even faster in 2022. Around € 50 mn of the planned sum will also be spent on the wafer fab in Reutlingen, near Stuttgart. At Reutlingen, Bosch will invest a total of € 150 mn in additional clean-room space between now and 2023.

The investment in Penang, Malaysia, includes building a semiconductor test centre from scratch, where starting 2023, the centre will test finished semiconductor chips and sensors.

Reutlingen Expansion Plans

In addition to expanding clean-room capacity in Reutlingen, Bosch has announced further ramp-up of chip production in Dresden earlier than planned.

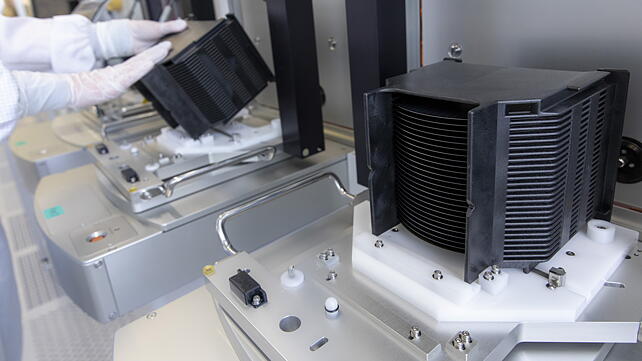

In two stages, a total of more than 4,000 sq m will be added to the current 35,000 sq m of clean-room space in Reutlingen. The first stage with 11,500 sq m of clean room space for 200 mm wafers has already been completed. The new facility has been producing wafers since September. The capital outlay for this came to € 50 mn in 2021), said Harald Kroeger, member of the board of management, Robert Bosch GmbH.

In the second stage, a further 3,000 sq m of clean-room space will be created by the end of 2023, which will attract another € 50 mn investment in both 2022 and 2023. In all, the company is creating 150 new jobs in semiconductor development at its Reutlingen location.

Bosch expects these investments will help the industry respond well to the increased demand for MEMS sensors and silicon carbide power semiconductors.

Bosch has invested over € 2.5 bn in its wafer fabs in Reutlingen and Dresden alone since 200 mm technology was introduced in 2010. In addition, it has invested billions of euros in developing microelectronics, the company said.

Penang Test Centre

The new Penang test centre will be a highly automated and connected factory, which will perform testing of semiconductor chips and sensors starting in 2023. The test centre will cover an area of around 14,000 sq m, including clean rooms, office space, R&D and training facilities for up to 400 associates. This new location in Asia is expected to shorten delivery times and distances for the chips.

The company said it has over 100,000 sq m of land available on Penang’s mainland strip, which will be developed in stages. The additional testing capacity in Penang is intended to open up the possibility of locating new technologies in Bosch’s wafer fabs in the future, such as silicon carbide semiconductors in Reutlingen, said the company.

In Conclusion

“Bosch can draw on its specific semiconductor and automotive expertise to develop superior electronic systems. This benefits our customers and the countless people, who want to continue to enjoy safe and efficient mobility in the future,” Kroeger said.

It must be noted that Bosch has been producing semiconductor components for over six decades, making it one of the few companies that has a deep understanding of microelectronics as well as expertise in electronics and software.

Production in the 300 mm wafer fab in Dresden started in July of this year – six months earlier than planned. The chips made in the new plant are initially being installed in Bosch power tools. For automotive customers, chip production started in September, three months earlier than planned.