For sustainable product design at Continental, one of the world’s leading technology companies, substituting classic petroleum-based raw materials with recyclable and bio-based raw materials is crucial.

Surface Solutions, one of Continental’s business divisions, is also working on degradable solutions in the development processes. As part of its current sustainability measures, the division is focussed on efforts to substitute critical contents and minimise emissions and odours. This focus is essentially driven by the need for sustainable mobility in the wake of the global climate challenge.

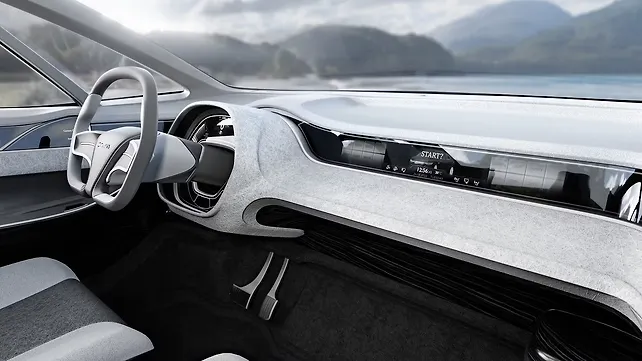

“Our sustainable product design is based on three pillars: carbon neutrality, circular economy and unique product properties as enablers,” said Dr Dirk Leiß, Head of the Surface Solutions business area, Continental. He said the company has already achieved considerable success with its products on this path to sustainable vehicle interiors. “In this way, we can now create customer-specific surface solutions that are up to 100% climate-neutral,” explained Leiß.

Continental will present sustainable and functional surface solutions for the diverse requirements in the driver’s cab at the upcoming IAA Transportation in Hannover, Germany.

Bio-based products

One of the examples of Continental’s surface material is Xpreshn, which can already be produced with renewable raw materials. Xpreshn provides a solution that is both light and environmentally friendly. “With bio-based Xpreshn, we can deliver a product with an optimal CO2 footprint that combines excellent technical properties and a large range of design options,” said Dr Gabriele Wittmann, Head of Global Surface Research, Continental.

Xpreshn, used as a material for door panels and instrument panel, can also be realised as a completely recyclable monomaterial, which means that it can be returned to the circular economy in its entirety.

Further, Xpreshn also offers solutions for recycling concepts with entire components, if the carrier component and the surface are made of the same materials, for instance. Then they can be recycled together at the end of their service life, said the company.

It must be noted that the development of single-variety composites – monomaterials – enables recycling processes from which high-quality raw materials for new or original products can be generated. Continental said it has already developed numerous products that possess these properties and also retain their proven premium properties.

Acella synthetic leather is a good example of a durable product with recycled materials and bio-based raw materials combined with a rPET textile. The yarns to produce the textile for the rear coverings are made from recycled plastic bottles. As a robust and easy-to-clean product with a range of highly variable designs, Acella whets the customer’s interest in sustainable products and does not compromise on product properties, Continental explained.

“We can already offer our customers premium surface solutions that are 100% carbon neutral,” said Wittmann. The key here is substituting classic petroleum-based raw materials with bio-based, CO2-based or recycled raw materials.

Wittmann also said Continental’s surfaces are designed for maximum performance and are also lightweight and robust, which essentially leads to lower CO2 footprint for the product and a vehicle’s energy consumption.

He further stated that Continental’s staynu technology makes surfaces resistant to contamination and mechanical & chemical stress caused by cleaning agents, making the surfaces durable. Currently, the staynu technology is mainly used on seats and add-on parts, but in the future, it will also be possible to use it for the instrument panel.

With sustainability at the core of its approach, Continental continuously develops innovative surface solutions with unique product properties. In this way, their solutions enable the realisation of sustainable vehicle interiors and positively contribute to the vehicle’s life cycle assessment.

Benova Eco Protect is one such product that stands for more sustainability, durability and comfort in the vehicle interior, claimed Continental. It represents an essential milestone in the development of sustainable vehicle interiors. The innovative material is exceptionally hard-wearing and highly durable. It also offers new possibilities for interior design trends, the company said.

Note: Continental will showcase its sustainable surface solutions at Booth C29 in Hall H12 at IAA Transportation 2022.

Also Read:

Continental Puts Forward Future Product Strategy At 2022 Annual Shareholders’ Meeting

Continental Expects To Close FY With €40.1 Billion In Sales

Continental Showcases Digital Solution For Cargo Space Calculation