As part of GE’s focus on industrialising new service technologies to support customers, OC Robotics, a GE Aerospace company, is now taking orders for its advanced Blade Inspection Tool (BIT). The BIT tool is part of OC Robotic’s 360 Inspection System, a family of tools designed to help standardise the inspection of GE and CFM engines.

The BIT is an on-wing kit that provides MRO shops with faster, more accurate inspection assessments for GEnx engines using Artificial Intelligence (AI) technology. The processing time for BIT is around 1.5 hours compared to around three hours for Borescope inspection (BSI).

Nicole Tibbetts, Chief Manufacturing Engineer, MRO, GE Aerospace, said, 'Our BIT technology is a great example of how we are innovating new ways to create service solutions for our customers. Industrialising BIT technology enables MRO providers to use this state-of-the-art tool for fast, accurate assessments of GEnx HPT blades.'

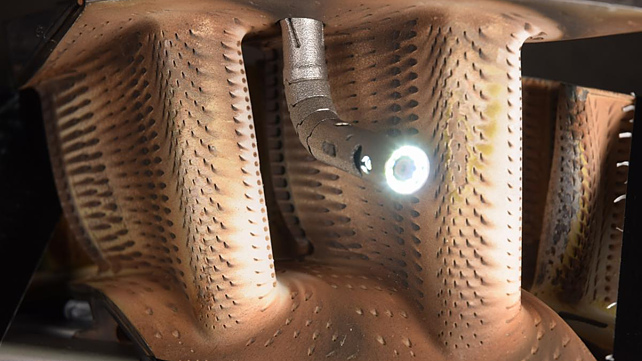

Using BIT technology will provide GEnx-1B and -2B customers with a clear and consistent insight during High-Pressure Turbine (HPT) Stage 1 & Stage 2 blade inspections. Blade inspectors with integral cameras capture images with cutting-edge AI technology, extracting and presenting them for review. In addition, BIT enables the user to measure both lines and areas on blade surfaces to accurately assess the condition of hardware.

Traditional borescopes use stereoscopic tips to generate a 3D map of the environment and require regular calibration. BIT uses consistent images of the blade and knowledge of the blade geometry to provide a simple measurement process.

Adam Mallion, Technical Sales Director for GE Aerospace, said, “Traditional borescopes also lack the ability to steer and navigate inside some very tight spaces of the engine. Our BIT technology allows operators to get consistent images with the same angles and viewpoints every time.'

In December 2022, GE Aerospace announced the formation of its Service Technology Acceleration Center (STAC), dedicated to developing engine services technologies and work processes.

Also Read

BHEL Joins GE Power Conversion To Develop Integrated Electric Propulsion Systems For Indian Navy