The auto component industry is the backbone of the Indian economy, with a 2.3% contribution to the GDP and giving employment to about five million people, Kenichi Ayukawa, President, SIAM and MD and CEO, Maruti Suzuki India, has said.

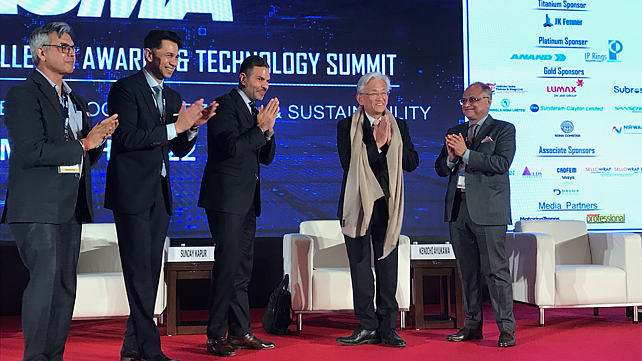

Participating at the inaugural function on the occasion of the 7th ACMA Technology Summit & ACMA Atmanirbhar Excellence Awards 2021, Ayukawa said, in FY 22, despite facing a slow start, the auto components market has seen a growth in demand for both the domestic and export markets. Furthermore, in the changing scenario of the global automotive market, the Indian auto industry has a prominent role in driving this change both in terms of skill and a manufacturing hub, he added.

Thanking the support from the Indian government through various schemes, Ayukawa noted that this will encourage the industry to be completely self-reliant. To make the industry sustainable and globally competitive, more such measures are being taken by the government and the industry, he noted.

Concluding his remarks, the SIAM president urged the industry players in these demanding and challenging times to keep safety as the highest priority both in terms of industrial and health safety.

Further focus on quality will ensure that the Indian auto industry places a strong foot in the global market, and also keeping a check on minimising the environmental damage in the manufacturing process will make the industry sustainable.

Delivering his address, Sunjay J Kapur, President, ACMA & Chairman, Sona Comstar, said the Indian auto component industry is facing severe headwinds due to the ongoing semiconductor shortage issue and Russia’s invasion of Ukraine.

He said that the unprecedented escalation in raw materials cost is threatening the industry’s viability, especially for some of the Tier-2 and Tier-3 companies. However, the Indian government’s support, especially the modified FAME-II, Production Linked Incentive schemes for Advanced Chemistry Cell (ACC) Battery and another for the Automobile and Auto Component industry, has enabled the industry to thrive.

The auto component industry in the first half of fiscal 2021-22 has grown to $26.6 billion, registering 65% growth. Further exports grew by 76% to $9.3 billion while imports increased by 71%t to $8.7 billion, leading to a trade surplus of $ 600 million.

Additionally, the aftermarket, estimated at $5.3 billion, also witnessed a steady growth of over 25%. Going forward, the auto component industry now needs to focus on being ahead of the curve in adopting new technologies, manufacturing practices, business models and thereby emerging globally competitive, Kapur noted.

The apex body representing India’s auto component manufacturing industry, through its ACMA Pillar on Skilling & Mentoring initiative, has transformed 1,200 manufacturing plants to become world-class.

Furthermore, it has set up a Centre of Excellence at the Sonipat Campus of IIT Delhi with state-of-the-art labs for mechatronics, Industry 4.0, Design and e-mobility. Additionally, it collaborates with IIT Bombay for its Centre of Excellence on EVs.

ACMA is currently working on developing an ‘Indian Standard for calibration of the automotive supply chain’ - the ACMA Capability Maturity Model. This rating model will help the OEMs confidently choose the right component partner.

Krishan Pal Gurjar, Minister of State for Heavy Industries & Power Government of India, graced the occasion.

Talking on the Technology Summit & ACMA Atmanirbhar Excellence Awards, Vinnie Mehta, Director General, ACMA, said that as per the recommendation of the jury, seeing the changing scenario of the industry, the committee has added the Excellence in digitisation and the Excellence in Localisation categories among the other five categories, such as Excellence in Human resource practices, Excellence in Exports, Excellence in Health Safety and Sustainability, Excellence in new product design and development and Excellence in manufacturing.