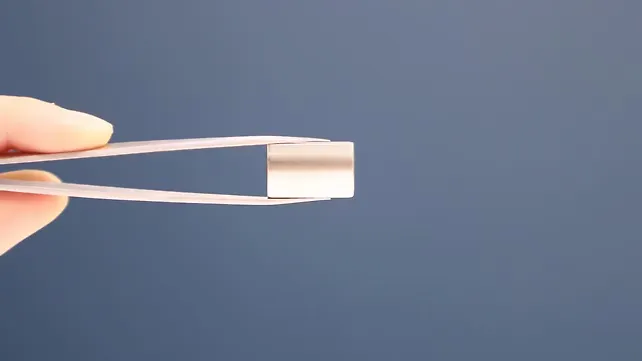

LG Innotek has developed an 'eco magnet' in collaboration with the magnet company SGI (Sunglim Group Industry).

According to LG Innotek, this is by far the world's strongest magnet and will minimise the use of heavy rare-earth (HRE) metals that have high scarcity values. This magnet is essential for vehicle motors, smartphone cameras, audio speakers, and wind power generators. It is installed in products that require driving and provides power with its magnetic pushing and pulling force.

The magnet significantly reduces the use of HRE metals, a key ingredient of magnets, by 60% compared to the previous product. It will help the industry which is struggling to find alternatives of HRE metals due to their lack of supply, high price, and environmental pollution caused. The company's development of the eco magnet is particularly significant as South Korea imports most of the HRE metals from China.

According to the company, the product has raised the magnetic performance for home appliances and vehicle steering motors to 14.8 kG (in kilogauss, magnet strength), which is the world's highest level, the company said. This beats the products of Japanese companies that have led the industry for nearly 40 years.

The industry believes that the technical performance limit of this magnet is 15kG. However, the magnetic performance of products commercialised so far is only 14.2 to 14.3 kG.

The advantage of the eco magnet is that it uses only 40% of the HRE metals compared to the previous one. This minimises the risk of production interruption due to a lack of raw material supply, the company said.

Automakers and vehicle components companies are showing interest in this magnet because they have struggled to reduce the proportion of HRE metals in their products. These companies are sensing the increasing risk of production interruption by a shortage of HRE metals supply. HRE metals can only be produced in certain countries; however, the demands have soared recently due to the increase of electric vehicles. In addition, their supply is expected to get even tighter as these materials are becoming 'weaponised' over diplomatic disputes.

For instance, applying the eco magnet to a steering motor of a vehicle is advantageous for reducing the vehicle's weight. The magnet reduces the size of the motor while increasing its output; the high magnetic power enables high motor output with a small size. The product is suitable for electric and hybrid vehicles that need weight reduction to improve mileage range (fuel economy of electric vehicles) due to an increase in battery weight. The magnet can also cut raw materials such as copper used in motors as it decreases the motor size.