The €59 billion BASF Group, having its portfolio in Chemicals, Materials, Industrial Solutions, Surface Technologies, Nutrition & Care and Agricultural Solutions, announced that the leading automotive systems supplier MAHLE has commercialised a plastic transmission support bracket made with BASF’s innovative material solution Ultramid A3WG10 polyamide (PA). Ultramid A3WG10 is a specialised high filled material solution for chassis and structural parts.

The new transmission support bracket weighs about 50% less than the conventional bracket, and therefore, it enabled to improve energy efficiency for a more sustainable drive. Additionally, the manufacturing process is simplified with the injection moulding process. Besides, Ultramid reduces the NVH of the parts to provide a more comfortable ride due to its excellent damping properties.

In addition, the material development company has supported MAHLE with its proprietary simulation technology Ultrasim, which effectively helps reduce trial and error during the development phase.

Sanghae Suh, Director, BU2 KR, MAHLE, said, “As the automotive part is exposed to various dynamic and static load while driving, it has to withstand the same load as if it were made of the conventional metal material. We were able to replace the whole structural part from metal to Ultramid, owing to its excellent mechanical properties. The transmission support bracket is MAHLE’s first structural application business launched globally, and the strong support from BASF helps us successfully penetrate the market.”

Desmond Long, Vice President, Business Management Transportation, Performance Materials Asia Pacific, BASF, said, “Partnering with MAHLE on this project is a great showcase of our ability to co-create new applications with our customers with advanced material solutions and technical support. We not only provide a customised material solution to meet their specific needs but also support them in realising their sustainability goals.'

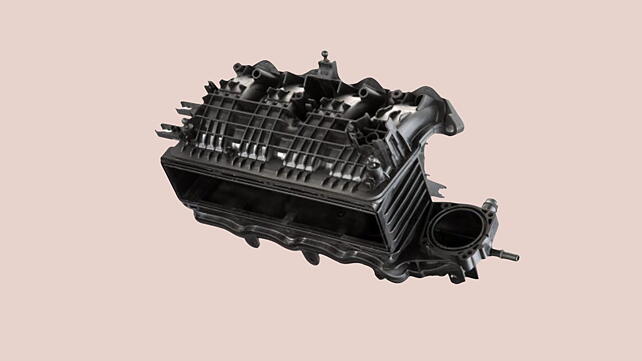

NB: Photo (of a part made by Ultramid) is used for representational purpose only.