In a bid to digitise the performance of new sustainable automotive-grade polypropylene (PP) compounds, Sumika Polymer Compounds Europe, a leading manufacturer of thermoplastic compounds, has joined the Manufacturing Intelligence division of Hexagon.

According to a press release from the company, the arrangement will enable engineers to design more recyclable components and offer a lower carbon footprint for future vehicles.

Sumika Polymer Compounds’ short glass-fibre polypropylene (GF-PP) Thermofil HP and recycled polypropylene (GF-rPP) Thermofil Circle materials benefit from sustainable manufacturing and recycling processes and offer carmakers performance equivalent to incumbent engineering plastics, but with an up to 60% lower carbon footprint. A growing proportion of today’s PP components are recovered and recycled compared to polyamides (PA), of which up to 70% are utilised in waste-to-energy initiatives or finished up in landfill, but there remains substantial room for improvement. The company said that these new Sumika recycled PP compounds are designed for the circular economy, contributing to plastic waste reduction at vehicle end-of-life.

Plastics can contribute up to 20% of the total weight of a car, and their application is escalating with the continuing replacement of metals.

The automotive industry’s shift to eMobility has increased the need for lightweighting components to maximise the energy efficiency of vehicles and mitigate the considerable weight of battery packs, but product development teams must also consider their environmental performance throughout the lifecycle.

Sridhar Dharmarajan, Executive Vice President & Managing Director, Hexagon India, said, “With aggressive sustainability targets and an increased focus on recycled materials, there is growing demand from Indian automotive companies and OEMs for sustainable materials. However, adoption has been slow because getting an accurate understanding of the characteristics of recycled materials is often a difficult proposition. Our partnership with Sumika will help address this challenge to a large extent and boost adoption of sustainable materials in India.”

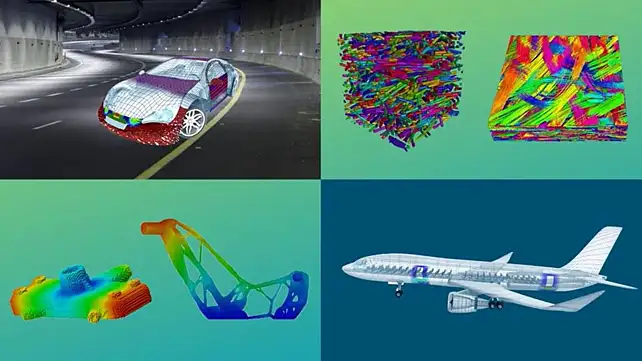

Guillaume Boisot, Head of the Materials Centre of Excellence, Hexagon, said, “Limited material behaviour data is a barrier to sustainable eMobility innovations because automotive engineering teams have not been able to put new materials through the rigorous virtual durability and safety tests required for automotive endorsement. Our unique multiscale material modelling technology accelerates the adoption of SPC Europe’s ground-breaking recycled materials by making it possible for product development teams to accurately simulate a component and subject it to established automotive engineering test and validation.”

Also Read: