Vivek Salvi is the Director, Transportation and Mobility, Dassault Systemes India. With a work experience of over 25 years, Vivek largely worked in the automotive industry with some key stakeholders in the Indian mobility marketspace. In the last 14+ years, he has been associated with Dassault Systemes working with some of the biggest Indian as well as global automotive customers and has led digital transformation initiatives for several of them.

Can you provide insights into the performance of the division under your leadership at Dassault Systèmes in 2023?

In 2023, Dassault Systèmes achieved strong double-digit growth in the transport and mobility sector, exceeding expectations. This success is attributed to the increasing adoption of technology by our customers. Looking ahead, we anticipate this positive trend to continue over the next few years, driven by our commitment to innovation in product development. Our focus on staying at the forefront of technological advancements ensures that our solutions meet and exceed market demands, particularly in the dynamic landscape of transport and mobility. The optimism for the future is grounded in the belief that our dedication to innovation and the ongoing adoption of technology will sustain our success in the evolving market.

How is the 3DEXPERIENCE (3DX) platform adapting to meet the evolving needs of the automotive industry, particularly in the realms of connected vehicles and SDVs?

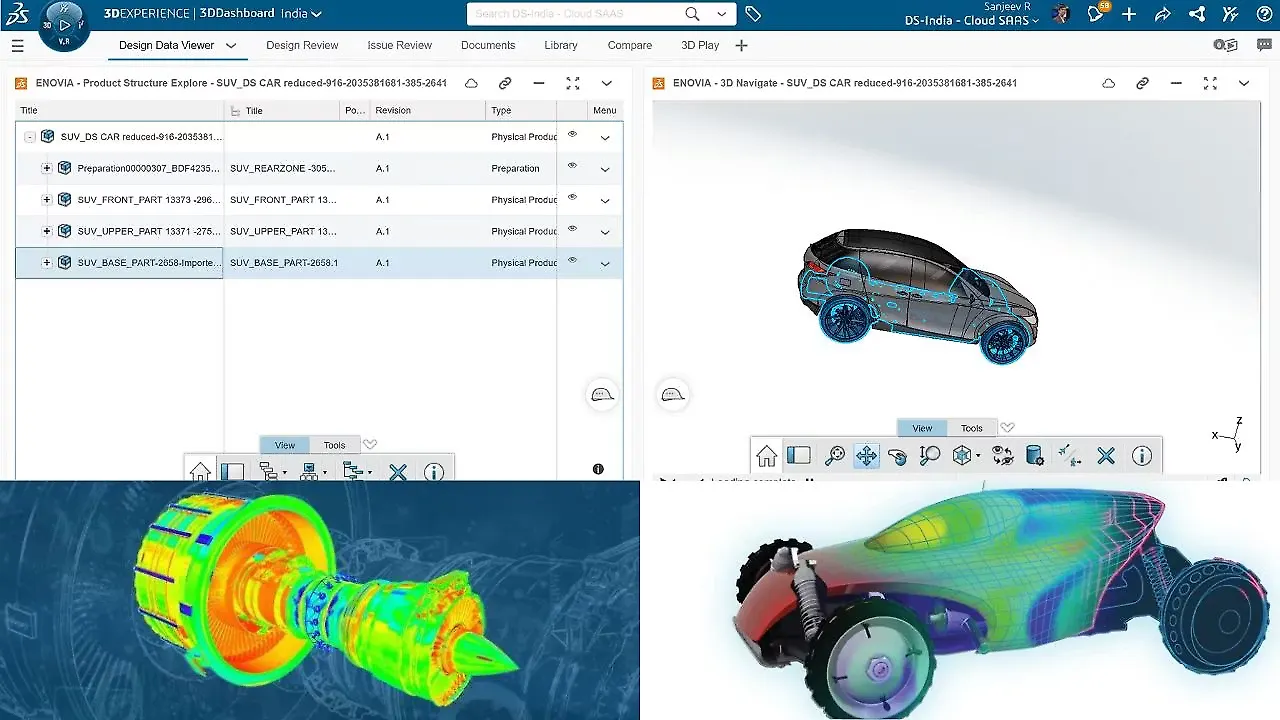

The widespread adoption of Dassault Systèmes' 3DX platform in the automotive sector is attributed to its openness, enabling seamless collaboration within organisations and with key suppliers. The platform's ability to connect geometric, requirement, functional, logical, and physical models (RFLP) is crucial for the development of connected vehicles. In the context of Software-Defined Vehicles (SDVs), the RFLP approach is key, and Dassault Systèmes, with its industry solutions and Software République initiative, is poised to address advanced mobility challenges effectively.

Can you elaborate on the potential applications of 3DX in optimising design for manufacturing, design for assembly, and design for service within the mobility sector?

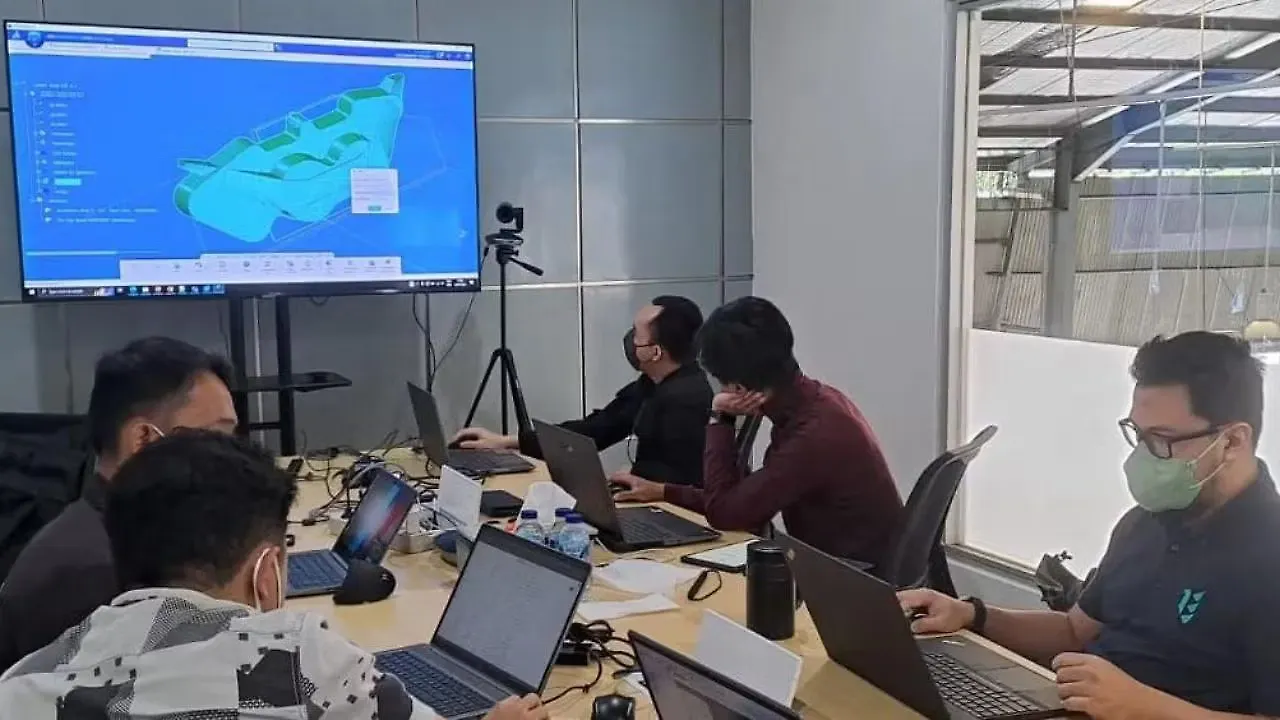

The 3DX platform serves as a comprehensive business and innovation solution, offering organisations a real-time, holistic view of their business activities and ecosystem. By seamlessly connecting people, ideas, data, and solutions in a collaborative environment, 3DX empowers businesses of all sizes, fostering innovation, production, and trade in unprecedented ways. Acting as a unified source of truth, the platform anchors outcome-based processes and consolidates all activities in one central location. This secure connection facilitates collaboration among individuals, teams, departments, and external collaborators, enabling the transformation of ideas into innovative products, services, and experiences.In the context of the mobility sector, 3DX assumes a critical role. As automotive Original Equipment Manufacturers (OEMs) collaborate with their Tier-1 and Tier-2 suppliers, there is a pressing need for a collaborative environment. 3DX addresses this need by providing a platform where stakeholders can collaborate early in the product development and validation phases. This collaborative approach ensures a smoother and more efficient workflow, particularly in the dynamic and complex landscape of the mobility sector.

Given the disruptive influence of 3D printing in manufacturing, along with challenges like part shrinkage, how does Dassault Systemes support in overcoming these issues?

Manufacturers aiming for greater sustainability have avenues to achieve this goal, such as reducing inventory, minimising energy consumption, and optimising transportation needs. The 3DX platform plays a pivotal role in supporting this shift by providing manufacturers with a visual representation of their machines in conjunction with materials. This visualisation capability enables them to calculate precise parameters for production. Importantly, this information can be seamlessly shared across the entire enterprise, ensuring reliability and trustworthiness in operations, regardless of where the component is printed.

As sustainability emerges as a central pillar in manufacturing practices, the advent of more potent and cost-effective Additive Manufacturing (AM) technologies is accelerating this shift. Leveraging solutions embedded within the 3DX platform that cover the entire spectrum of AM processes, manufacturers can seamlessly integrate sustainable manufacturing practices into their workflows. This integration allows them to reap the full benefits of sustainability without disrupting their product development processes significantly. The platform thus emerges as a comprehensive tool that not only facilitates sustainable manufacturing but also ensures minimal impact on established workflows.

Dassault recently established a strategic partnership with Cadence Design Systems, focusing on multidiscipline modelling to address the complexities of connected solutions. Could you shed more light on this initiative, particularly in the context of transportation and mobility?

Dassault Systèmes and Cadence have collaborated to integrate the 3DX platform with the Cadence Allegro platform, offering a joint solution that empowers companies to master the modelling, simulation, and optimisation of intricate electronic systems. This multidisciplinary solution accelerates the end-to-end system development process, allowing customers to optimise designs for performance, reliability, manufacturability, supply resilience, compliance, and cost. The partnership has been tested in a global production environment over several years, showcasing its effectiveness.The collaborative virtual twin experiences created through this partnership encompass electronic and mechanical product lifecycle management, business process analytics, and multidiscipline electronic systems development. This holistic virtual model provides a real-time view of electrical and mechanical simulation, manufacturing, and supply chain execution throughout the product lifecycle. This comprehensive perspective enhances decision-making and accelerates innovation through 'what-if' studies.Considering India's significant spending in the logistics sector, what contributions has Dassault Systemes made to the industry, especially in terms of innovative solutions?

Logistics holds a central position in our core business strategy, a fact underscored by our involvement in diverse logistics projects in India, notably the GatiShakti initiative. GatiShakti aspires to reduce logistics costs as a percentage of GDP from 14% to 18%. This reduction hinges on improved coordination, streamlined processes, and minimised bottlenecks in obtaining approvals across departments.

Emphasising the need for a unified information repository, often termed a 'single source of truth,' we champion the use of the 3DX platform. This platform forms the foundation for constructing a comprehensive logistics virtual twin, catering to the intricate needs of rail and ocean freight, trucking, last-mile connectivity, and the intricacies of intermodal logistics, integrating urban planning seamlessly.

In addressing the contemporary complexity of goods transportation, where customers may opt for varied routes from point A to point B, we provide a robust virtual twin platform. This platform enables customers to plan, simulate, optimise, and deliver tailored logistics experiences using the 3DX platform. Our overarching ambition is to offer innovative solutions that align with market demands and contribute significantly to shaping the logistics landscape.

In light of the ever-evolving preferences of end-consumers, how can Dassault Systemes support OEMs and large suppliers in creating vehicles that cater to the concept of cars as a second home?

The concept of cars as a second home revolves around enhancing the in-vehicle experience, ensuring comfort, safety, and entertainment for passengers. Dassault Systèmes facilitates this paradigm shift by providing a collaborative environment where OEMs and suppliers can work seamlessly together. Through virtual twin capabilities, stakeholders can simulate and iterate the interior design, connectivity features, and overall user experience, ensuring that the vehicle becomes an extension of the consumer's lifestyle.

Our platform supports the development of intelligent, connected vehicles equipped with features that cater to the diverse needs of passengers. From advanced infotainment systems and personalised climate control to innovative seating arrangements, the 3DX platform serves as a comprehensive tool for envisioning and refining every aspect of the in-car environment.Cybersecurity is a growing concern in the automotive industry. How can Dassault Systemes contribute to safeguarding the sector from cybersecurity issues?

In this context, the 3DX platform plays a pivotal role, providing groundbreaking applications that establish end-to-end digital continuity across diverse disciplines. Specifically, it supports conceptual design, embedded systems, and software development for intelligent cars. Adopting a systems engineering approach through the platform, car manufacturers gain the capability to comprehensively manage complex tasks associated with vehicle development. This approach is instrumental in creating vehicles that are not only smarter and safer but also deliver higher performance. The platform's innovative applications empower organisations in the automotive industry to navigate the intricate landscape of vehicle development, contributing to advancements and improvements in the field.

What are your strategic plans for you in the Indian market?

We are looking at five key and very specific strategies for the India market to help and support our customers in meeting customer demands and contributing to the reduction of carbon footprint with Virtual Twins. The first strategy focuses on Green Energy Transition & Sustainability with the objective of reducing the carbon footprint across products and operations, extending to the supply chain. The approach involves leveraging Virtual Twin technology for sustainable practices and environmentally friendly solutions. The second strategy centers on Electric, Connected & Autonomous Vehicles, aiming to drive success in next-generation vehicles through advanced shared intelligence, systems engineering, and multi-domain collaboration. The third strategy, Mass Production to Mass Customisation, seeks to enhance visibility, efficiency, and control in manufacturing production and operations, both globally and locally, with an approach to transition from mass production to personalized manufacturing. The fourth strategy, Quality, Regulations, Cost, aims to ensure high-quality standards, meet global and local regulations, and minimise expenses to unlock profitable opportunities, utilising comprehensive solutions for quality control, regulatory compliance, and cost-effectiveness. The final strategy, End Customer Experience, focuses on dreaming, exploring, validating, and seamlessly producing innovative mobility options to meet the expectations of global consumers. The approach prioritises customer-centric design, validation, and production processes to enhance the end-user experience.

Also Read:

Cadence Partners With Dassault Systèmes To Transform Electronic Systems Development