Aditya Singh is the Founding member and Head of Business at BosonQ Psi. He brings 3+ years of experience in Analytics and Management Consulting from leading global organisations, including ZS Associates & Tata Consultancy Services. His areas of expertise include strategy, customer success, and consulting.

How does Quantum computing help the mobility industry?

Quantum computing can transform the mobility sector by optimising material design and vehicle design, advancing vehicle innovations like alternate fuels, managing traffic, improving supply chains, enhancing vehicle design, and advancing autonomous vehicles. It offers the potential for more efficient and sustainable mobility solutions.

Have Indian organisations begun to see business value from quantum computing?

Yes, not only Indian organisations but the Government, along with industry and academia, are exploring practical applications with Quantum. The Indian Government recently approved the National Quantum Mission with a budget of INR 6,000 crore to accelerate Quantum technology-led economic growth.

Moreover, start-ups, with BQP one of the first start-ups to provide simulations with a quantum approach, are actively participating and leading in evangelising quantum computing. BQP has tie-ups with companies like Tech M and Quest Global, among others, along with universities and colleges to promote Quantum in India and other global markets, including the US and UK.

Therefore, quantum computing is seen as a significant opportunity for Indian businesses to gain a competitive advantage and create new business models. The technology is expected to have applications in areas ranging from drug discovery, logistics and supply chain optimisation, financial services, and more. However, significant challenges remain in terms of the availability of skilled professionals, quantum-safe encryption standards, and the high cost of quantum computing infrastructure.

With India announcing Bharat NCAP, do you see more applications for your solutions?

While the concept of predicting behaviour using linear, non-linear, and multi-body dynamics is well-established, the specific implementation and integration of such solutions into the Bharat NCAP framework would require collaboration among regulatory bodies, automotive manufacturers, and technology providers.

Bharat NCAP shares its core objective with Global NCAP to ensure that vehicles meet stringent safety standards. Both programmes aim to enhance vehicle safety and reduce the likelihood of fatalities and injuries in road accidents. However, there are notable differences in their approaches and specific requirements.

One significant difference is that Bharat NCAP currently focuses on voluntary compliance for vehicle manufacturers, while Global NCAP is often used for mandatory safety certifications in various countries. This distinction raises questions about the enforceability of safety standards in India and the effectiveness of voluntary compliance.

In Global NCAP, a vehicle must get a minimum of 34 points – 16 points for the front crash test, 16 for the side impact, and two points for seatbelt reminders -- to get a 5-star safety rating for adult occupant protection. However, in Bharat NCAP, to receive a 5-star rating, a vehicle needs at least 27 points in adult occupant protection and requires 41 points in child occupant protection.

Meeting compliance standards and achieving favourable NCAP ratings heavily depend on a vehicle's crashworthiness. This involves sophisticated simulations, crumple zone optimisations, and structural enhancements to ensure occupant safety during a collision. As technology advances, simulations will become more complex and shift from component to system levels.

Typically, these simulations take much time and compute power. Many iterations are needed to arrive at the optimum level, and there is room for improvement with a more efficient approach.

Quantum computing has the potential to significantly augment simulation in various ways, particularly in solving complex problems that are computationally challenging for classical computers.

What kind of growth do you predict for BQP in the coming years?

The addressable global simulation market for classic computing analysis is expected to grow from $21 billion in 2023 to $51 billion in 2030. Quantum simulation unlocks the untapped high-performance market, yielding a classical + quantum total addressable market to grow from $70 billion in 2023 to $170 billion in 2030.

BQP is focused on the high-growth mobility sector, which accounts for 45% of the new opportunity, yielding a Serviceable Addressable Market (SAM), which is predicted to grow from $31 billion in 2023 to $53 billion in 2030.

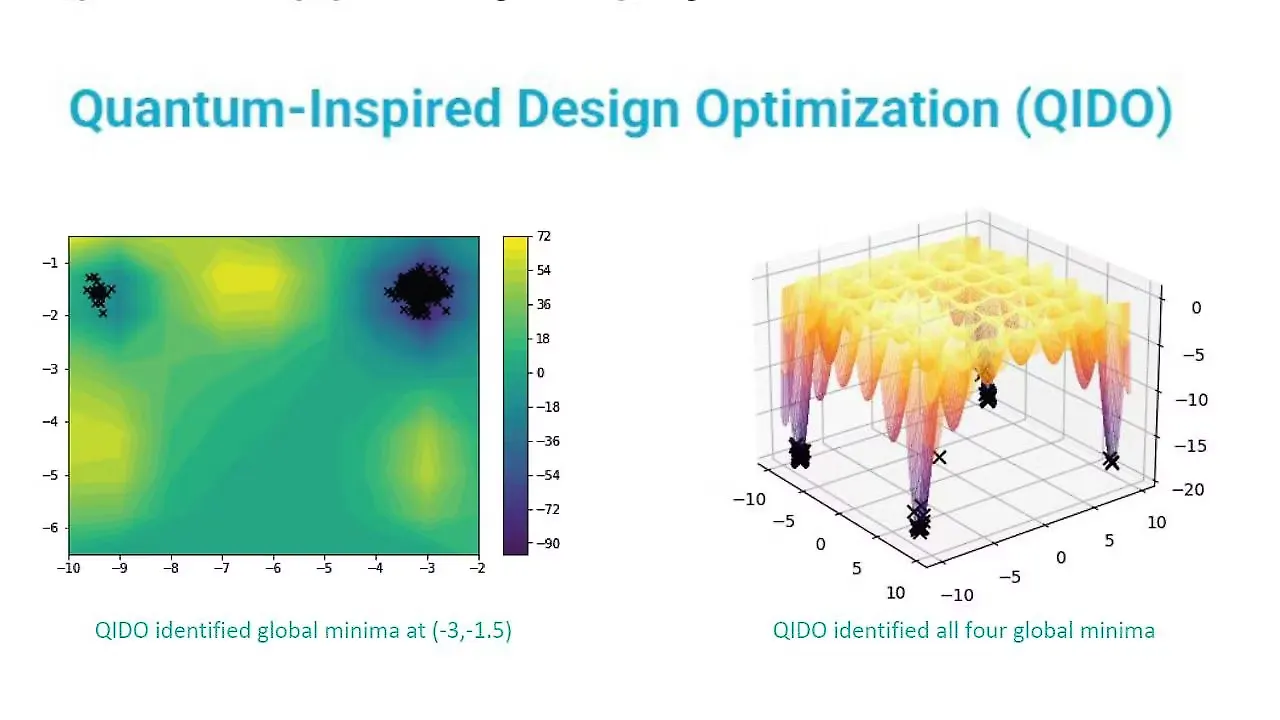

Our financial projections are $1 million in the first year, $5 million in the next year and $12 million in the following year. Our investment will be used to launch the BQPhy Quantum-Inspired Design Optimization (QIDO) design optimisation product to early design partners and generate initial commercial sales.

What is your offering for electric vehicles (EVs) where the challenges are in enhancing range, reducing charging times and doing away with several issues, including thermal runways?

BQP offers the simulations with Quantum Algorithms – an industry first. The power of Quantum computers is showcased by their ability to perform the same simulations in much less time compared to classical supercomputers. Hence, this technology can significantly help EV manufacturers in their time to market.

Moreover, obtaining high accuracy from simulations is vital in using them in the product development process. Since high-accuracy simulations took much time before, making them prohibitive, quantum-powered simulations can now enable the manufacturers to perform accurate simulations at a reasonable time, in hours instead of months. Added accuracy will not only help companies create more efficient designs and improve the reliability of their vehicles but also help save lives.

In addition, the speedup from Quantum computations enables lower computing usages, decreasing the overall cost and making it affordable for EV manufacturers.

Simulations can be of various types, some of which are thermal (studying the effect of heat and temperature on an object), structural (studying the effect of an object’s strength, stress, and failure), fluid (studying the effect of flow in and around an object), and electrochemical (studying effect of chemistry on electricity). Thermal runaway is a complex engineering problem that entails all types of simulations. With the right simulation tools, simulations allow to mimic every possible physical condition, rising temperature, fast charging, or fuse placement and find areas of problem. After identifying, it can also aid in testing different solutions and avoid thermal runaway altogether.

How do your solutions help vehicle makers and Tier-1 suppliers accomplish sustainability goals?

Our solutions enable them to optimise the design and manufacturing processes, leading to lighter and more aerodynamic vehicles. This can result in reduced fuel consumption and lower emissions.

We assist in the evaluation and selection of sustainable materials and components that have a lower environmental impact in terms of production, usage, and end-of-life disposal. Our solutions incorporate lifecycle analysis capabilities, allowing manufacturers to assess the environmental impact of their vehicles throughout their entire lifecycle. This analysis includes evaluating the emissions associated with the production, use, maintenance, and recycling or disposal of the vehicle and its components.

We help them optimise their supply chains, improving efficiency, reducing waste, and minimising environmental impact throughout the value chain. This includes optimising logistics, transportation, and packaging.

Our solutions contribute to the development and optimisation of energy-efficient technologies, such as EVs, hybrid powertrains, and alternative fuels. By leveraging our solutions, they can make informed decisions, improve their environmental performance, and align with sustainability targets set by Governments, regulatory bodies, and stakeholders in the automotive industry.

Can you talk a bit about the Proof-of-Concept (POC) of BQPhy’s #Quantum-Inspired Design Optimisation solver that you offered for one of the OEMs in India?

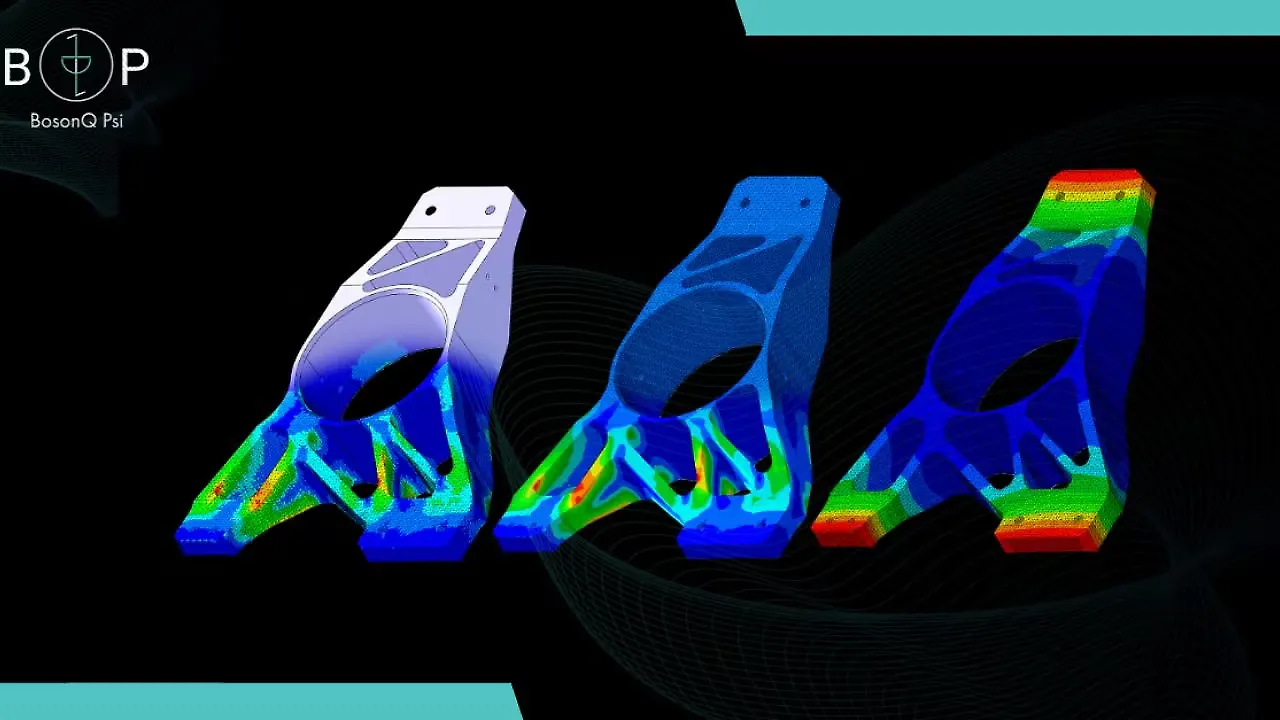

The aim of the POC was to explore the application of BQPhy's QIEO approach in topology optimisation to reduce weight in the control arm. The results of the POC were encouraging, demonstrating that BQPhy's QIEO converged faster and with fewer iterations compared to gradient-based and simulated annealing approaches. Additionally, the QIEO approach utilised significantly fewer computational resources.

The weight reduction achieved by BQPhy's QIEO was 3.2 times greater than traditional approaches, using only 8x less computational resources. This showcases its potential in addressing optimisation challenges in the automotive industry, such as topology optimisation for weight reduction in control arms.

Can you share your current and future projects in the automotive and aviation industries?

We work on ‘control arm optimisation by reducing weight. For a giant in the automotive industry, our BQPhy platform demonstrated its transformative potential by optimising the design of vehicle control arms. Through our sophisticated topology optimisation module, BQPhy successfully re-engineered the component's design, achieving a notable reduction in weight without compromising durability. This innovation not only promises enhanced fuel efficiency for vehicles but also solidifies BQPhy's position as a game-changer in automotive engineering, capable of delivering high-impact solutions that meet rigorous performance and safety criteria.

As we take our expertise in topology optimisation to new heights, we have entered a pivotal phase – optimising the Wingbox in the Aerospace sector. Through a compelling POC collaboration with a global aircraft manufacturing giant, we have substantially reduced the weight of the entire wing box structure, opening doors to cost-saving opportunities not just in manufacturing but also in operations.

Also Read:

Why Is Bosch Setting Up Start-Up For Quantum Sensing?

IonQ, Hyundai To Use Quantum Computing To Up Efficacy Of Next-Gen Batteries