Dr John Pinson was elected Chief Executive Officer in June 2022 and is responsible for Stanadyne’s global operations. Prior to being appointed CEO, he served more than a decade with the company, first as CTO and later as President. Dr Pinson has more than 30 years of experience in global emission compliance strategy and fuel injection system design. He began his career at General Motors with assignments in Powertrain and in Research and Development, focused on emission reduction technology.

In India, Stanadyne is catering to three-wheelers, which are transforming to EVs. How are you preparing your company to face new challenges?

In the market, there are applications ideal for electrification. The three-wheeler is one such example that is perfect, small, and lightweight, with the charging infrastructure in the urban segment.

But then there are many applications that are hard to electrify. As a company, we have strategically decided to support this internal combustion engine (ICE) segment, which is hard to electrify – like agriculture, industrial, gensets, etc. These applications are going to be very resistant to upholding electric conversion. So, we will continue with applications that are good for electric.

Also, there will be much work on hybrids, and then the ICE segments must also come along. Even three-wheeler haulage applications with high load cycles operating in rural areas, where electric infrastructure will not be there for some time, must be ICE. We cannot leave these applications behind.

Our company is working towards assisting with this transition, and during this time, there will be ICEs co-existing with electric machines, in addition to hybrids. Also, there will be ICE, which cannot be converted into electric. We must de-carbonise by making engines more efficient, and there is much opportunity to do this.

Can you elaborate on the opportunities that you see?

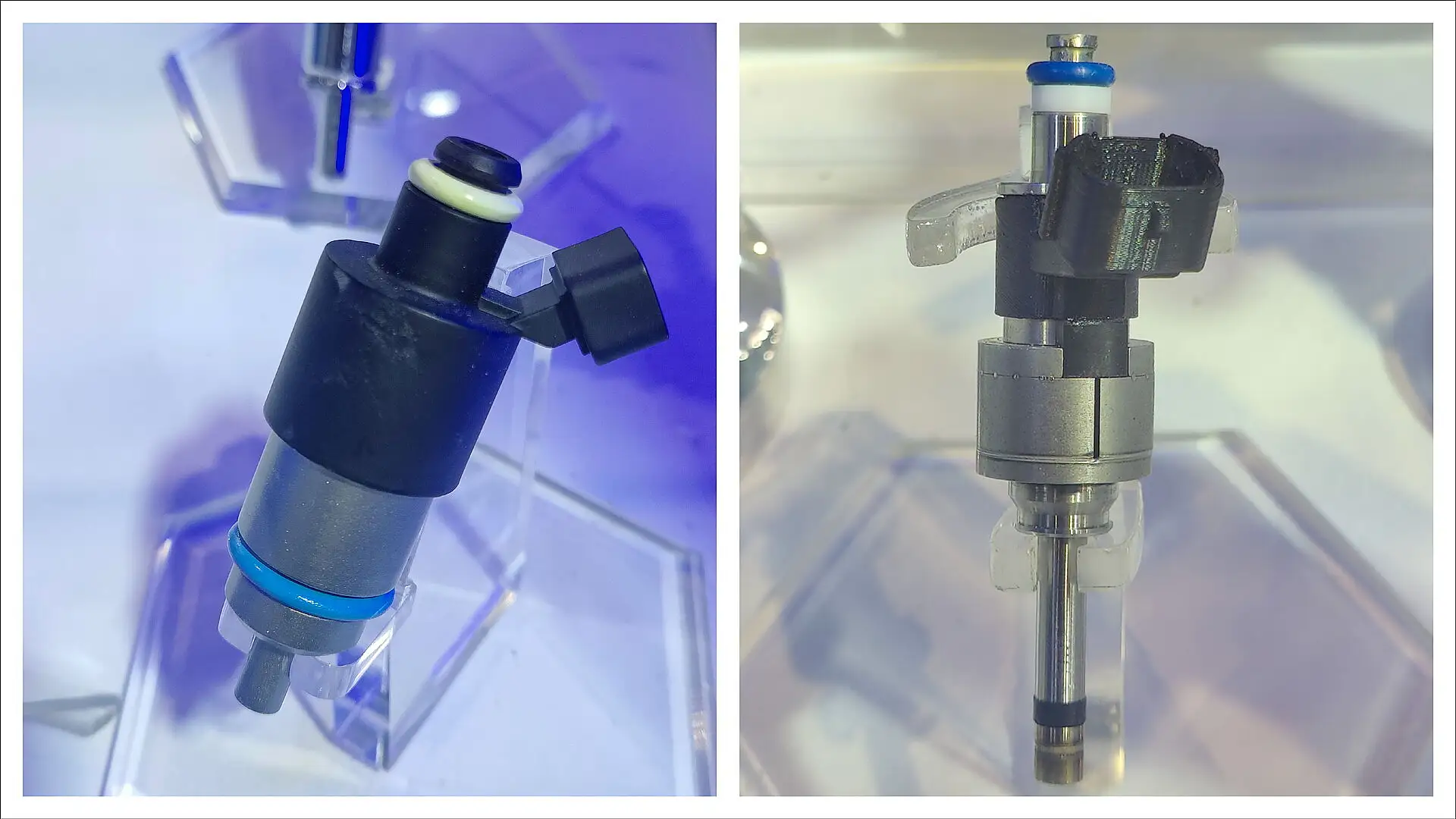

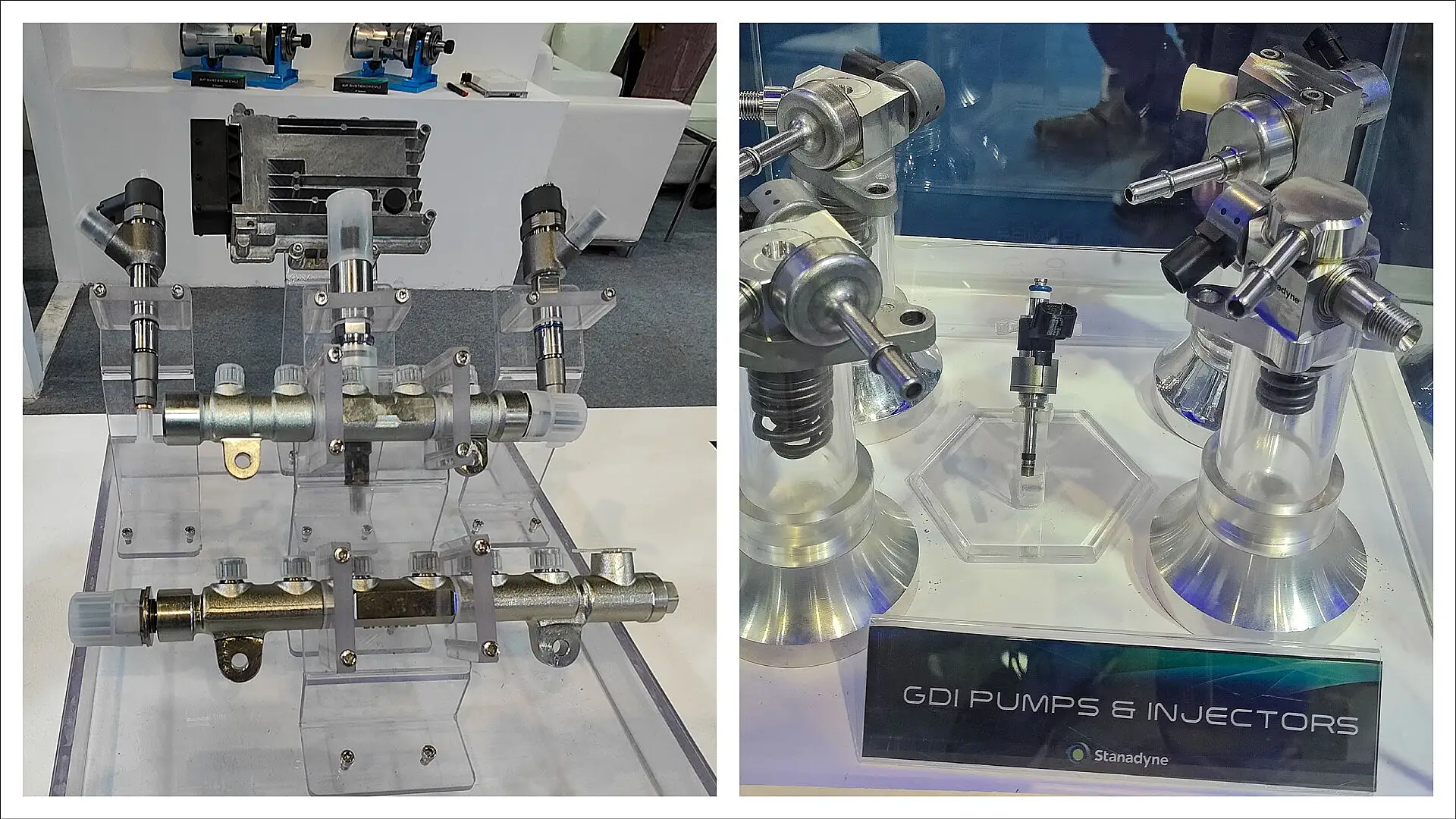

We are also looking at low-carbon fuels like bio-fuels and such things so that if we can’t take the engine out of the application, we can at least take the carbon out of the application. This is what we are focused on. Our latest products include high-pressure fuel injection, hydrogen injection, high-pressure gasoline injection and diesel injection systems.

We will also support these engines that are married to an electric machine (in the case of hybrid), making them more efficient and making tomorrow's engines far less carbon intensive. So, together, we bring the transportation sector to minimise carbon emissions.

Can you tell us about the development of hydrogen injectors?

We have hydrogen injectors and are working on the products with many customers. Hydrogen would be a niche application for some time because it depends on infrastructure. We acknowledge the weakness in the electric vehicle distribution and charging infrastructure and with hydrogen, these problems are even more significant. The generation, storage and distribution of hydrogen and the application themselves are very difficult. However, if we can overcome these challenges, we can create an engine that runs very successfully on hydrogen gas.

For what sort of applications are hydrogen injectors developed?

Right now, we do not have any commercial hydrogen applications. We are more in the development and demonstration phase. There are many problems to be solved, but it starts with having the injectors with which we can run the engines.

The natural progression is that those applications that can be electrified will bring great promise. However, we have alternative and low-carbon fuels for the application that cannot be fully electrified or hybridised.

Globally, we are in on-road Class V trucks. In India, we are on 1 MW gensets, and in the US, we are on pick-up trucks with higher hp, like 6L or 8L types of engines. In other parts of the world, we are in the larger engines.

One roadblock in the Indian market was that we did not have product offerings for the on-road segment. Therefore, we are bringing our niche products. We have hitherto been focusing on the off-road, industrial, and agricultural segments. That was our entry point.

Are you getting into the commercial vehicle segment in India?

Yes, particularly in commercial vehicles and construction equipment, we start from our base and then move on. Our competitors have been serving the on-road segment well. But now, with the current environment witnessing many changes, there is much effort taken on electrification and hybridisation.

In many places, ICE is under-supported. This is a problem because these engines must also advance because the regulations are absolutely on time. In order to comply with the Greenhouse Gas and efficiency regulations, OEMs have to bring the entire portfolio forward.

We see a big opportunity to enter the Indian market and other global markets, where we are not traditionally placed. We are heavily in the on-road segment in China and the US, and now we see an opportunity in India to bring products for hydrogen-electrified commercial applications.

When you enter a new market, you must bring key differentiating elements aligned with the customers’ needs. Can you tell us about your unique offerings?

The key differentiator is fuel systems, not software. Injection pressure has been one of the key drivers for the improvements we have seen in diesel, where we started with 600 bars and went up to 2,700 bars for the lighter applications. We are bringing a 3,000-bar platform for diesel engines, and this will typically work for larger commercial vehicles where we need compatibility benefits. This will be starting with the 200 hp and 250 hp applications, going up to larger applications.

For gasoline passenger car applications, injection pressures have come up from very low levels – from 150 bar to 200 bar, and then we think the next stop on the slab is 350 bar. We see tremendous advantages in following the same trajectory that diesel had.

We are leapfrogging as we already have 1,000-bar gas injectors, bringing next-generation fuel injection systems to the market. As we look to our OE customers worldwide, we see a great deal of enthusiasm about this because these systems are not being developed today.

Why do you say so?

The supply base is trying to respond to all new requirements with electrification and hybridisation, and we take the opportunity to double down and focus on the next-generation fuel systems. It is true that eventually – although there are declining vibes – about 50 million ICE still should be with us even in 2050, and these must be supported. So that is where we are choosing to invest.

What about supporting the new mobility ecosystem?

We will support electrification in suitable areas like control valves, specially machined components for hybridisation, etc. That’s our core portfolio; we will participate here as necessary. Our major initiative is to bring forward next-gen high-pressure fuel injection systems.

Globally, what is your strategy for business development?

In the past, we gravitated towards providing components. Only some of our competitors are willing to serve individual components. So, we made a strategic decision a few years ago to change our approach and start offering systems. I am very glad we did because, in today’s world, our customers are also expected to implement ‘the system as a whole.’ They honestly find it difficult to do the integration themselves.

We now provide the core systems in sensors, lines, rails, different components, control systems and software. This would enable our customers to take further steps that they need to take in terms of engine testing and application development. We implemented it in our India facility. These initiatives will increase our share rather than an individual component.

To what extent will it enhance the revenue for the company?

From a growth rate, we plan to triple our Indian business in the next three to five years. Our Chennai facility is fully utilised, and we will be looking to expand in other regions. We are looking at a few areas in the North-West. We will expand as we bring these products to market.

What about the major markets in the world?

We are bringing high-pressure injection systems for gasoline and diesel engines to the US market. We see great acceptance and good feedback about the next-generation systems. Certainly, there is much excitement about the next-generation fuel system in the US, China and Europe.

How was the year 2022 for Stanadyne?

Sales for 2022 were around $260 million. We are looking now to grow that substantially with these new products.

Would you cross a billion-dollar in the next five years?

The goal is to triple the size of the business in the next five years. It is not that we have a higher win rate. It’s not a volume game; it’s more of value, despite low volume.

In that case, do you need to invest in some of the markets?

There will be substantial investments in India, especially now, with the rise of India and with the redistribution of priorities happening in the global supply base. We see India as a huge market for component supply. The India operation is already producing components for all global operations. We will also be investing in infrastructure and new product launches.

We have invested a lot in developing an engineering centre in India. Many of the products that we have now are developed in India. We are one of the few companies serving China out of India, which is the trend. Today, about 65% of components made in India are exported to China. However, we want to keep a balance. We do not want only exports, as the growth potential in India is very strong.

What kind of capex are you planning across facilities worldwide?

Our business is highly capital intensive, and because of the nature of the progress of the programme, we plan to invest about INR 200 crore in India (approximately $24.3 million) in three to five years. We will invest around $100 million in the rest of the world.

What are the new opportunities for you?

We specialise in high-tolerance, speciality steels, coatings, control valves, and magnetics, and these types of parts and materials are used in hybrid transmissions, cooling systems, electric vehicles, battery systems, etc. Therefore, we are now looking to see how we can apply these extreme levels of expertise in high-speed, small magnetics, and electro-mechanics in the new breed of powertrains. This is where we are pushing ourselves.

Also Read: