Pratt & Whitney's (P&W) litany of woes with its revolutionary Geared Turbofan (GTF) engines shows no signs of letting up, with a significant portion of PW1100G-JM engines powering Airbus A320neo jetliners having to be removed from the aircraft within the next nine to twelve months, for earlier inspections than scheduled.

The engine maker made 200 accelerated removals by mid-September this year and is working to minimise impacts on its customers. These issues have cost P&W orders from IndiGo and Air India, who recently placed large orders for Airbus A320neo family aircraft.

While revealing Q2CY23 results, Greg Hayes, Chairman and CEO, RTX (parent company of P&W), stated that the issue would require the removal of certain engines from service for inspection earlier than expected.

A rare condition in the powdered metal used to manufacture certain engine parts requires accelerated fleet inspection, and it will not impact GTF engines currently in production.

Geared For Trouble

The Minister of State for Civil Aviation, Gen V K Singh, stated that many of the A320neo aircraft fitted with PW1100G-JM engines, operated by Indigo and Go First, were grounded due to supply chain issues related to the engine. “As intimated by the Directorate General of Civil Aviation (DGCA), the situation is due to lack of hardware to get the engines repaired and overhauled and is a global issue impacting all customers of P&W,” he said. Forty-three IndiGo and 27 Go First aircraft powered by these engines have been grounded. Go First blamed P&W for driving the airline into insolvency due to GTF engine issues, grounding 50% of its fleet by April 2023.

IndiGo CEO Pieter Elbers said the carrier was stable when planes were not operational due to supply chain challenges. “It's relatively stable, it changes on a daily basis, but the overall number itself is around the high 30s; we have taken many mitigating measures to deal with that situation.” He said, however, that aircraft not operational had to be looked at in the context of IndiGo’s overall fleet size, which is a little over 300 airplanes.

In 2017, IndiGo faced issues with PW1100G-JM engines related to premature degradation of the combustor chamber lining and wear of the No. 3 bearing seal, resulting in many engine removals, as sufficient spare engines were unavailable.

Damage Control

Currently, about 10% of P&W’s GTF-powered fleet is out of service. The company had planned for Aircraft On Ground (AOG) rates to come down by 2023, with more engines being returned to service than removed for maintenance. In May, P&W returned more engines from MRO than its customers had removed for servicing. However, the latest accelerated removals and inspections announcement for the PW1100G-JM engine could again put today's aftermarket capacity to support the fleet under stress.

“To meet our customers’ expectations, we need to be able produce highly efficient, reliable engines that are also highly durable, with long time on wing between shop visits,” said Rick Deurloo, President, Commercial Engines, P&W. “However, this metric is not yet at the level we expect, which has put stress on the operations of the fleet.”

P&W also says it has improved wing time since the programme's inception. Its overall durability and lifecycle are better than the older V2500 as the GTF engine’s time on wing maturity rate, eight years into its service life, compares favourably. The company has more design enhancements planned in 2024 and 2025 to extend the time on the wing further. About 75 % of the GTF fleet operates with airlines in cooler environments, and these customers are experiencing time on-wing rates that P&W expected at this point in the programme.

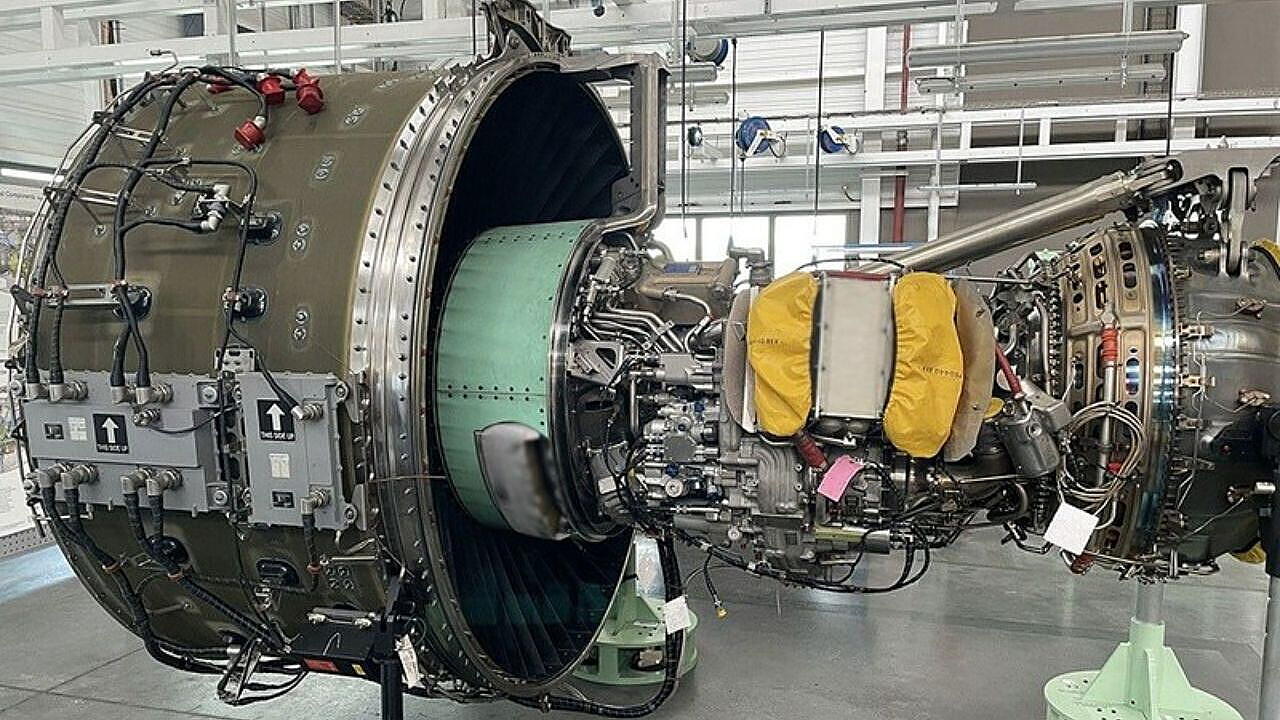

Durability upgrades introduced by the engine maker include the latest- configuration Block D hardware, which has been deployed in 60% of the fleet, and is set to increase to over 90% in the next two to three years. This latest build standard alleviates removal drivers with longer-life parts, including life-limited parts like integrally bladed rotors, a durable combustor, and improvements in oil seals and turbine airfoils. The Block D time on the wing is double the prior configuration. Since the GTF engine first entered service, it has met the target level for dispatch reliability – or the ability to depart on time for a scheduled flight – which is now at 99.96%.

Support Mechanism

P&W has been globally expanding GTF Maintenance, Repair & Overhaul (MRO) capacity to address the aftermarket demand. “We are focused on growing GTF engine aftermarket output by increasing material availability and expanding global capacity across the GTF engine MRO network,” said Deurloo.

The engine maker is also accelerating steps to address persistent industry-wide supply chain constraints and has increased casting production by over 40% year to date. The MRO network has doubled in size since 2019. There are now 13 active locations worldwide, with six more slated to be operational by 2025.

Revolutionary Turbofan

The geared fan architecture is widely acknowledged as one that will proliferate in the future and can be considered a once-in-a-generation programme, delivering about 20% less fuel and CO2 per trip and up to 25% per seat. P&W has so far received over 10,000 GTF engine orders and commitments from about 90 customers worldwide, powering Airbus’ A220 and A320neo families and Embraer’s E-Jets E2 family, including E190-E2 and E195-E2 model aircraft.

GTF engines currently power about 1,600 aircraft, carrying over 860 million passengers across six million flights and accumulating more than 23 million flight hours. Since its entry in 2016, the GTF engines have saved nearly five billion litres of fuel and over 12 million metric tonne of carbon emissions.

The engine uses a new architecture using a reduction gearbox between the fan and the low-pressure shaft together with the low-pressure compressor and actuating turbine. The gear system separates the fan from the low-pressure compressor and turbine, allowing each module to operate at optimum speeds. The larger diameter engine is allowed to rotate slowly, and the engine’s low-pressure compressor and turbine can rotate faster due to the gear system, which results in lower fan pressure ratios needed, resulting in higher bypass ratios.

The GTF engine has fewer stages and 2,000 fewer airfoils than conventional turbofan engines, making it lighter and more efficient with reduced maintenance. An early operator of the GTF engine on its A320neos, IndiGo, in 2017 stated that these aircraft were 15 % more fuel-efficient than their older A320ceos (without sharklet wingtip extensions).

However, the engine’s promise of efficiency has been dented by continued reliability issues with operators in hotter, sandier environments. This led to lowered aircraft availability and increased operating costs, an anthemion for the GTF engine’s airline customers, who are razor focussed on keeping their operating costs as low as possible.

Also Read:

Airbus Joins Pratt & Whitney, SAF+ To Accelerate SAF Research