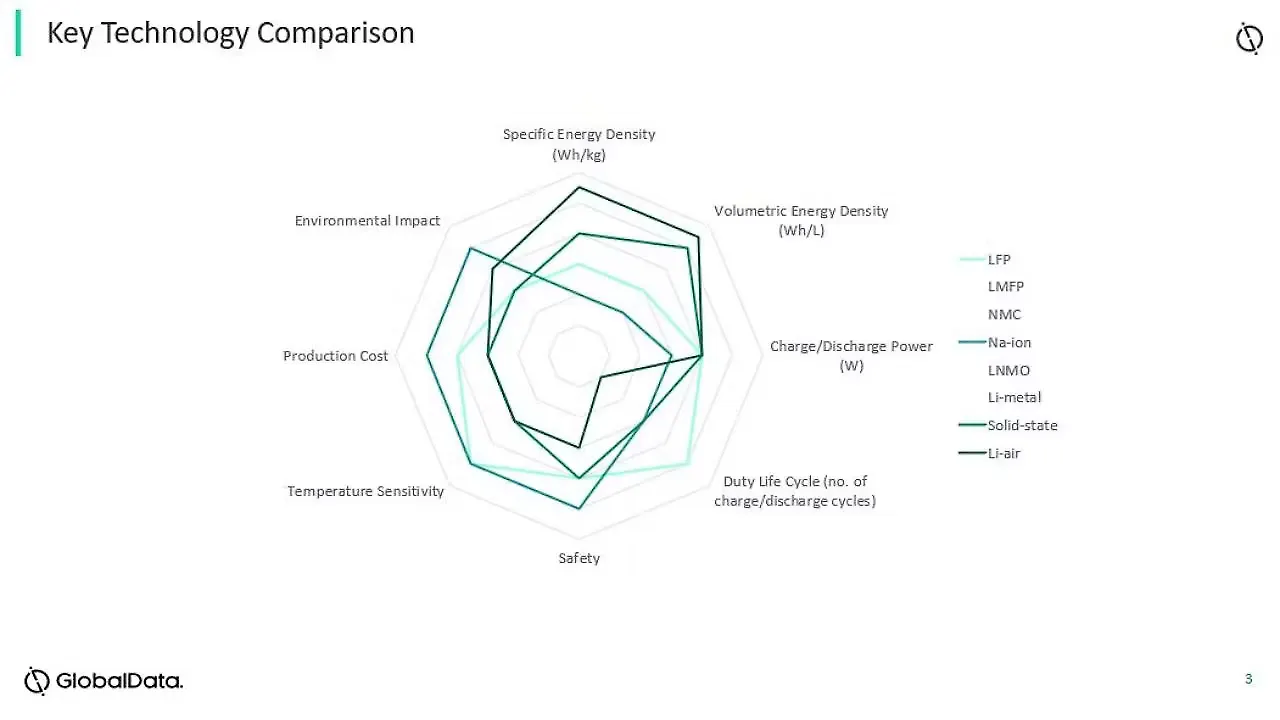

Battery technologies for electric vehicles are evolving quickly with newer concepts under various stages of development.

Among the various battery chemistries now emerging, sodium-ion is seen as a strong contender to lithium-ion batteries (LIBs) for automotive applications, especially in mass market battery electric vehicles. It is the only viable chemistry that does not contain lithium.

Sodium-ion batteries (SIBs) require cheaper raw materials, are more cost-effective, sustainable and better for the environment. Naturally, they are an attractive option for the automotive industry.

“Sodium is one of the most abundant elements on Earth, making SIBs a more economically viable choice compared with LIBs that rely on constrained lithium availability,” says Oliver Petschenyk, Automotive Powertrain Analyst, GlobalData.

The sodium reserves in the earth’s crust are believed to be more than 500 times more abundant than lithium. “Sodium’s less precarious supply enables potentially lower production costs, making SIBs an attractive option for BEVs,” he adds.

Unlike LIBs, SIBs do not need expensive copper as a current collector in the anode. This, alongside sodium, brings significant cost advantages in the overall production and gives SIBs the edge over LIBs.

“SIBs are much cheaper than LIBs with sodium carbonate being much cheaper than lithium carbonate. They are also expected to be much easier to recycle and thus have a relatively lower impact on the environment,” says Rohan Kanwar Gupta, Vice President and Sector Head – Corporate Ratings, ICRA.

Lithium Getting Dearer

Lithium carbonate prices have been increasing steadily over the last two years: 4-5 fold in 2021, continuing through 2022 and nearly doubling between January 1, 2022, and January 1, 2023, according to the International Energy Agency (IEA).

The sodium carbonate market is expected to grow at around 6.1% CAGR between 2022 and 2030, while demand for automotive Li-ion batteries increased by about 65% to 550 GWh in 2022 from about 330 GWh in 2021.

Moreover, the extraction of sodium is more sustainable than that of lithium. “SIBs have a smaller environmental footprint than LIBs. Lithium extraction can be environmentally damaging, involving extensive mining and chemical processing. Sodium extraction, on the other hand, is more sustainable, reducing the ESG impact associated with BEV battery production,” says Petschenyk.

The harmful effects of LIBs on the environment start right from lithium mining, which leads to contamination of local ecosystems. The extraction process leads to more carbon dioxide production while other toxins are exposed to the environment.

LIBs have other chemicals such as manganese, cobalt, and nickel that are also harmful to the environment when not properly handled. On the other hand, SIBs do not require any major extraction process, because of which the carbon footprint and environmental impact are in check.

SIBs also pose a lower risk of thermal runaway or fire hazards associated with LIBs since, as Petschenyk says, sodium is much less chemically reactive than lithium.

“Be it newer chemistries within lithium-ion or nanomaterials, we are seeing innovation in all aspects of battery technology. The concept of SIB is not new to the battery community. Initially developed with LIBs, sodium-ion was left behind as lithium-ion offered better prospects,” explains Rajeev Singh, Partner and Consumer Industry Leader, Deloitte Asia Pacific.

Host Of Challenges

According to him, the key challenges in making SIBs are on the technology front which is still in the early stages of development. The supply chain of raw materials is yet to get established which limits scaling up production.

Other drawbacks of SIBs are on performance since they have low energy density and shorter lifecycle coupled with realities of slow charging and heavier/ undeveloped manufacturing infrastructure. Moreover, they cannot easily be developed into various shapes which restricts their versatility across segments.

“SIBs can charge up to 80% in 15 minutes and have high thermal stability at around -20° C with a charge retention capacity of more than 90%. These features make them attractive for automotive applications,” says Singh.

Anand Kulkarni, Chief Product Officer and Head of High Voltage Programs, Tata Passenger Electric Mobility, says matured SIBs are expected to be strong competitors for LIBs given that they are considered to be one of the most stable and safest chemistries. “If the ongoing research around SIBs can resolve current challenges, they can be a cost-effective replacement for LIBs in specific applications and markets,” he adds.

SiBs score over LiBs

| SiBs | LiBs |

| More Economically viable as sodium is in abundance on Earth | Expensive as lithium is in limited supply |

| SiBs offer improved safety as sodium is less chemically reactive, reducing risks of thermal runaways or fire hazards | LiBs less safe than SiBs as lithium is highly chemically reactive, making fire hazard risks a concern |

| SiBs have smaller environmental footprint as they do not require extensive mining and are more sustainable | LiBs have larger footprint as they require extensive mining activity and chemical processing |

| SiBs require less expensive metal – aluminium – as a current collector in the anode | LiBs require more expensive – copper – as a current collector in the anode |

| SiBs attract lower production costs due to input costs and processes | LiBs continue to struggle on production costs due to high input costs and processes |

(Inputs from LMC Automotive report)

Many global carmakers have already announced their sodium ion (Na-ion)-powered electric cars. One example is the Seagull by BYD and Sehol EX10 produced by the VW-JAC joint venture. Likewise, Chinese battery maker CATL and BYD plan to integrate Na-ion batteries in all models below USD 29,000. At present, the best-selling BEVs of BYD include Dolphin and Wuling Mini.

According to an IEA report, the first models powered by Na-ion batteries will be slightly more expensive than the cheapest small BEV models in China that sell around USD 5,000-6,500. The range with Na-ion batteries could be between 250-300 km and EVs powered by this technology are scheduled to be available in 2023-24. Na-ion batteries are expected to bring down the cost of EVs by 20-40%.

Other Applications

“Many startups are also working on SIBs, including UK-based Faradion, HiNa Battery Technology in China, Tiamat in France, Altris AB in Sweden, and Natron Energy in the US. Most of them are looking to develop SIBs for non-auto applications such as stationary storage. With time and evolution, we will see adoption of these batteries for other applications as well,” adds Singh.

India prominently uses LIBs and lead-acid batteries owing to their affordability as well as access to material and technology. However, the downside is social, environmental, and safety-related issues at a time when the country is moving towards sustainable and clean energy options.

Indian companies are gradually making inroads into the SIB segment and Reliance Industries’ buyout of Faradion, a leading SIB maker, for USD 135 million is a case in point. Likewise, KPIT Technologies and its German carmaker clients have been working on Na-ion battery technology to replace lithium-ion in certain segments of the auto market. Indi Energy, a startup working on battery technology, has successfully developed Na-ion batteries.

“India’s locally-made BEV cell batteries are being sorted into two- and three-wheeler segments. In the case of short-range mobility, there is a need to transition from lead-acid batteries to more cost-effective alternatives. Na-ion batteries are being considered as one possible solution for these,” says Kwan Wongwetsawat, Senior Analyst – Asia Powertrain Forecasts, GlobalData.

With Na-ion batteries showing lower energy density than lithium-ion phosphate batteries, “we expect India’s Na-ion batteries to first find application in the two- and three-wheeler segments where range requirements are relatively lower”. Wongwetsawat goes on to add that this allows for the initial adoption of Na-ion technology while further steps are taken to “enhance its energy density for use in four-wheeler applications”.

Featured photo courtesy: Mercom India

Also Read:

Amara Raja Starts Work On Telangana’s First EV Batteries Gigafactory