The increasing demand for electric vehicles (EVs), which are expected to be made lighter, fuels the demand for the global EV adhesives market to grow at a CAGR of 44.7% by 2026. The market size in 2021 is estimated to be $0.4 billion.

According to the report - Electric Vehicle Adhesives Market by application, resin type, substrate, form, vehicle type and region - Global Forecast to 2026, published by MarketsandMarkets, the market size is projected to reach $ 1.8 billion by 2026.

The leading players in the EV adhesives market include Henkel, H.B. Fuller, Sika, 3M, Wacker Chemie, Bostik, L&L Products, Jowat SE, Ashland, PPG Industries and Permabond.

Emerging ASEAN

The rising trade war tensions between the US and China and low labour costs in China have forced various end-users of adhesives to relocate and establish their manufacturing base in the ASEAN countries. This relocation is expected to increase the demand for adhesives in the ASEAN countries.

India offers low-cost labour, which can provide significant investment opportunities for companies. In addition, the government's initiatives such as 'Make in India' and the proposed scheme on entrepreneurship development may open up additional opportunities in the industrial and infrastructure construction segments. All these factors are expected to drive the market in APAC, the report stated.

Exterior Account For Largest Share

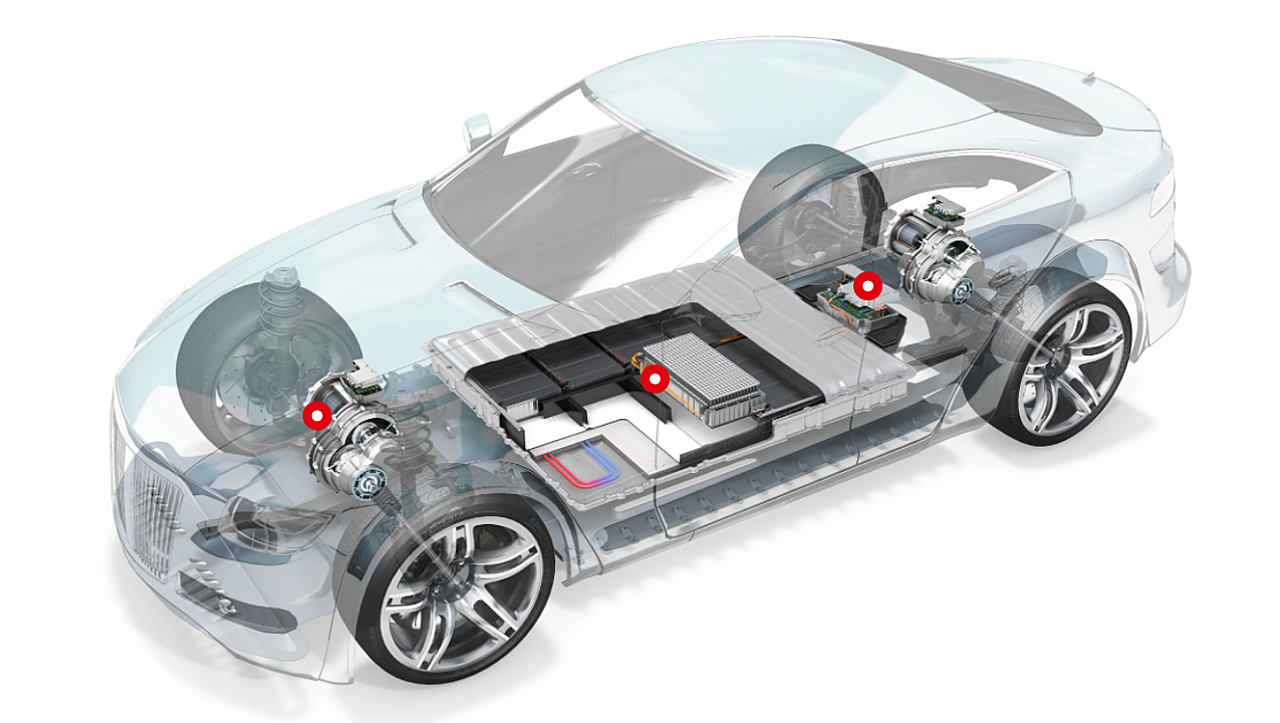

The rising production and sale of electric cars have increased the demand for batteries, electric motors, doors, instrument clusters, infotainment systems, seats, panels, and charging sockets. Batteries are the essential components of electric cars as they provide power to the car. The battery of the car is heavier than the other parts. To counter the weight of batteries and reduce the overall weight of electric cars, lightweight materials are used in electric car applications. In the EV industry, adhesives are used instead of welds, screws, rivets, gaskets, and fasteners, allowing automakers to make the vehicle lightweight. One of the concerns in EVs is range. Automakers are addressing this issue by increasing the battery capacity of the vehicle.

The design of EVs has to be lightweight to counter the weight of the battery system used in electric vehicles. Therefore, the bonding of dissimilar materials is done with the help of structural adhesives to replaces fasteners, rivets, and spot welding, which contributes to reducing the weight of vehicles.

According to the research firm, structural adhesives also address the issue of crashworthiness and safety of battery systems in electric vehicles. Furthermore, with the continuous development in technology, the consumption of adhesives in the exterior parts of electric vehicles will further increase during the forecast period.

Polyurethane Will Have The Largest Share

MarketsandMarkets stated that the use of adhesives in EV is expected to increase during the forecast period. The various applications of adhesives in EV require different types of adhesives derived from resins such as epoxy, polyurethane, silicone, and acrylic. Adhesives made of different resins have different properties and are chosen according to the specific application.

Polyurethane adhesives are made of urethane polymers. They exhibit extraordinary elasticity and elongation up to 600% before fracture. There are three types of polyurethane adhesives, two-component polyurethane, one-component rigid polyurethane adhesives, and two-component elastic polyurethane adhesives. The bonds of polyurethane adhesives are formed in two stages: firstly, the adhesive cools back down to reach the holding strength and, secondly, the adhesive uses the moisture to continue curing for hours to days to reach the final structural strength.

Electric Cars

The demand for EVs is increasing rapidly due to growing environmental concerns, even as the sale of ICE vehicles sees a slump. The implementation of favourable policies for EVs and technological advancements in the value chain will drive the EV market in the next five years. The growth of electric cars and buses is expected to drive the growth of EV adhesives during the forecast period.

Vehicle manufacturers announced increasingly ambitious electrification plans. Out of the world's top 20 vehicle manufacturers, representing around 90% of new car registrations in 2020, 18 have stated plans to widen their portfolio of models and rapidly scale up the production of light-duty electric vehicles, finds the report.

Policy Changes

The growth of electric cars is driven by critical policy changes adopted by leading countries in electric mobility. These countries have introduced stricter emission standards and incentives for electric cars and promote investments in the EV industry value chain to bring price parity between EV and ICE vehicles.

The research company said that the growing EV markets such as Europe, APAC, and North America will provide growth opportunities for EV adhesive manufacturers during the forecast period.

APAC accounted for the largest share of the EV adhesives market in 2020, followed by Europe and North America.

Courtesy: MarketsandMarkets. NB: Photo is representational; courtesy: Henkel.