Electric traction motors originally developed in the 1800s are still evolving with new designs, improved performance, and more considerations around materials. These are not just incremental improvements, with developments such as axial flux motors and various OEMs eliminating rare earth materials.

As electric motors are the driving force behind electric vehicles (EVs), IDTechEx expects over 100 million electric motors to be required per year by 2032 to meet the demand for the growing EV market.

According to the latest report from IDTechEx - Electric Motors for Electric Vehicles 2022-2032, there are several key performance metrics for electric motors, including power and torque density, that enables improved driving dynamics in a smaller and lighter package, with weight and space being at a premium in EVs. Another critical area is efficiency. Improving efficiency means that less of the precious energy stored in the battery is wasted when accelerating the vehicle, leading to improved range from the same battery capacity. Due to the many different considerations in motor design, the EV market has adopted several different solutions, including permanent magnet, induction, and wound-rotor motors. In many cases, a combination of options may be used to give the best overall solution. However, each has its pros and cons regarding performance, materials costs, and supply, with permanent magnet motors relying on rare earths with volatile pricing and a geographically constrained supply chain.

Emerging Options

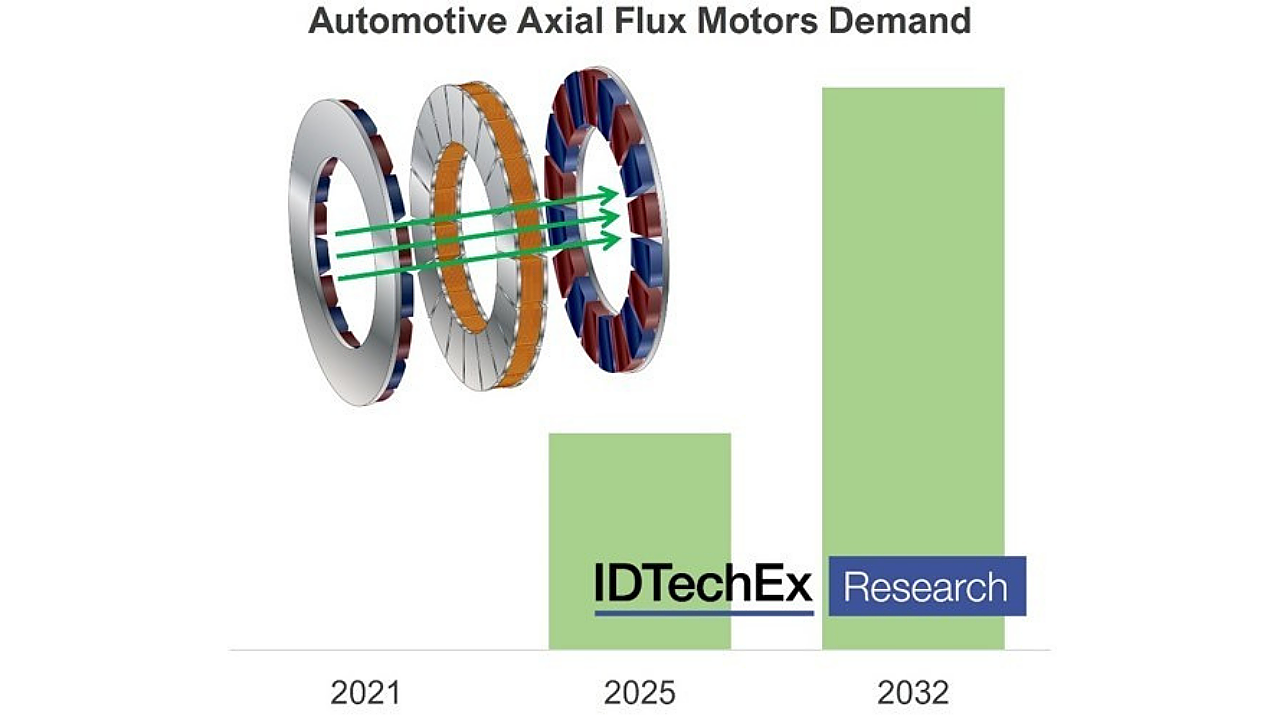

A key emerging motor technology is that of axial flux. The magnetic flux is parallel to the axis of rotation in an axial flux motor (compared to perpendicular in radial flux machines). Whilst almost the entire EV market is using a form of radial flux motor, axial flux motors present several benefits. These include increased power and torque density and a pancake form factor ideal for integration in various scenarios, the report said.

Despite the previous lack of adoption, the technology has evolved to the state where we have seen significant interest. For example, Daimler acquired key players YASA to use their motors in the upcoming AMG electric platform, and Renault has partnered with WHYLOT to use axial flux motors in their hybrids starting in 2025. The axial flux market in automotive EVs is very small today, but the research firm expects a huge increase in demand over the next ten years, with first applications in high-performance vehicles and certain hybrid applications.

IDTechEx also sees some promising applications for other alternatives to typical EV motors, such as in-wheel motors and switched reluctance motors. In-wheel motors can eliminate much of the drivetrain components that would normally take up space within the vehicle's cabin and provide benefits such as torque vectoring. Lordstown announced the use of Elaphe's in-wheel motor for its electric trucks, and other players like Protean are providing in-wheel motors to autonomous shuttles.

Switched reluctance motors are not a new technology but are making somewhat of a resurgence in certain segments with their design and control improvements. For example, advanced Electric Machines (AEM) provides commercial vehicles and develops a motor with Bentley. Switched reluctance machines are much simpler to manufacture than many others and utilise no rare earths; in fact, some like AEM and RETORQ motors move to aluminium windings to avoid copper, the research firm added.

Courtesy: IDTechEx. NB: Photo is representational.