Continental is working on the 'Digitalisation of the Industrialisation Process in the Automotive and Supplier Industries' (DIAZI) project by collaborating with a consortium of eight IT, process optimization companies, universities, and startups.

The project is managed by Continental's User Experience business area and funded by the German Federal Ministry for Economic Affairs and Climate Action.

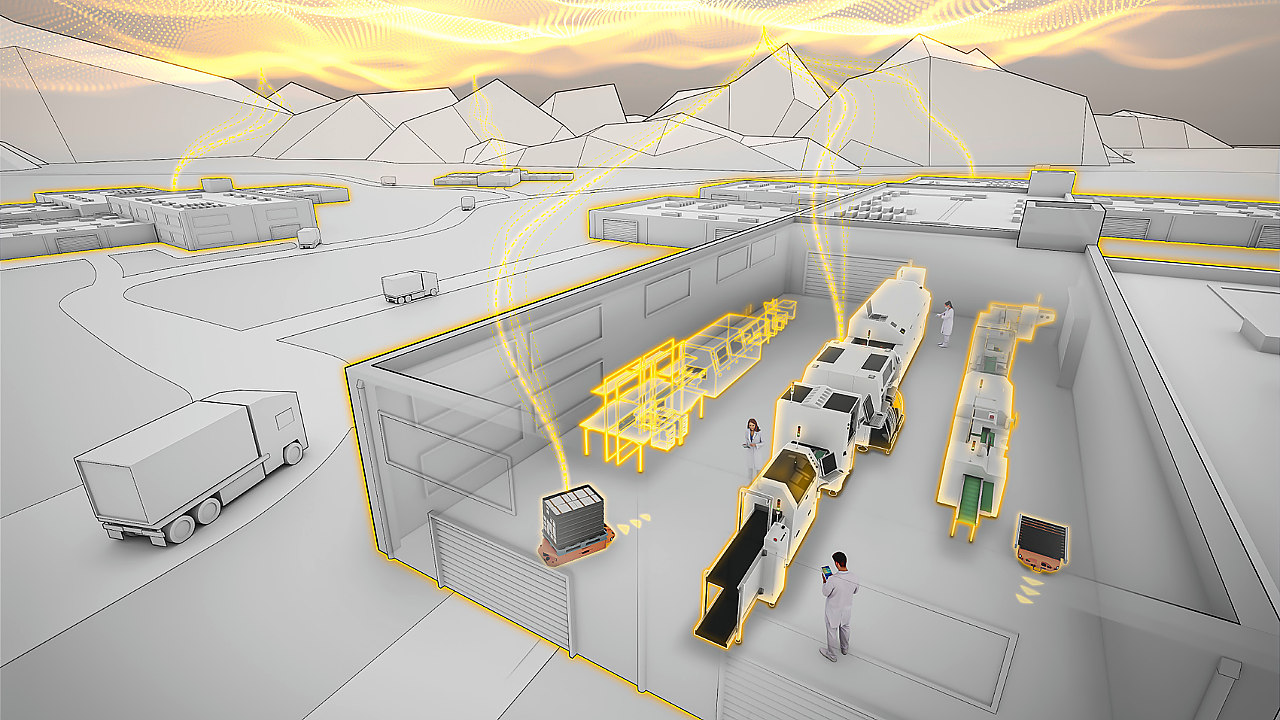

The primary objective of the DIAZI project is to transition production plants into the digital realm. This will enable the planning, simulation, and operation of new production lines in a digital environment, leading to increased efficiency, flexibility, and cost-effectiveness in modern automotive plants.

This transformation will help automotive plants keep pace with rapid development cycles, complex supply chains, and evolving customer requirements, ultimately contributing to more sustainable mobility.

Thomas Ebenhöch, head - operations for the User Experience business area, Continental Automotive, stated that DIAZI is a major step toward the digitalization of the automotive industry. “Continental is driving a new approach to effective and sustainable production processes in the automotive and supplier industries through digital simulation, artificial intelligence, and data management in the cloud. Our vision of the 'digital factory' is taking shape,” he added.

The DIAZI project promotes the concept of a 'digital factory,' a fully digitalized production environment where new production lines are digitally planned and production processes are simulated.

This approach allows for virtual startup and continuous optimization, powered by artificial intelligence and in-depth data analysis. It can connect various production plants and supplier sites for fast, scalable, and high-quality production.

The DIAZI project, funded by the German Federal Ministry for Economic Affairs and Climate Action and the European Reconstruction and Resilience facility, commenced on January 1, 2023, and is expected to run for around three years. Ernst Stöckl-Pukall, head - Digitalisation, Industry 4.0, Federal Ministry for Economic Affairs and Climate Action, said that there is significant potential in transforming the automotive sector into a highly digitalised industry.

Cooperation across company boundaries is a key component, and the findings and demonstrators from the project have the potential to drive the adoption of fully digitalised and AI-supported production processes in the entire industry, he added.

The initial phase of the project has focused on defining specific demonstration models across various areas of digitalisation, covering virtual line planning, data-based process optimisation, and application operation. Various experts and organisations have been involved in this phase.

Also Read

Continental Names Christopher Marsh As Head – Surface Solution, Pune Plant