As part of its initiatives to create fully networked factories, Volkswagen has announced that it is taking a further step in the direction by creating a local 5G standalone network at its main plant in Wolfsburg.

According to the vehicle maker, the campus network will initially cover the main production development centre and the pilot hall. The pilot project will test whether the 5G technology meets the demanding requirements of vehicle production, intending to develop this for industrial series production in the future.

The company said a dedicated 5G radio frequency will safeguard the secure and delay-free transmission of data. The Transparent Factory in Dresden has also put a so-called '5G island' into operation. In addition, VW undertakes setup and operation of the 5G infrastructure itself in a move designed to build up competitive expertise in using this vital technology of the future and ensure data security.

Real-time Data Transfer

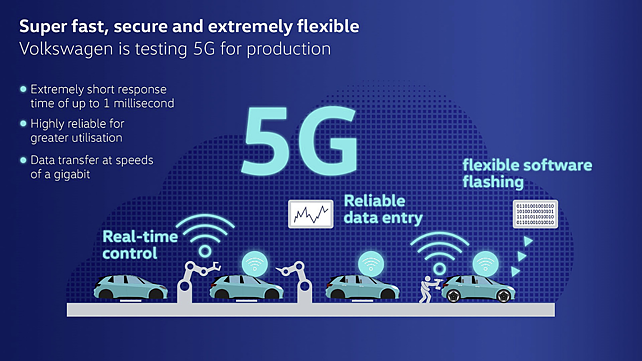

There are already around 5,000 robots at the VW plant in Wolfsburg and many other machines and systems. Secure, delay-free transmission of data will be required in the future to control and monitor these. Latency is significantly reduced with 5G networks versus other wireless communication technologies such as WLAN. The 5G technology provides short latency times of up to one millisecond, data transmission rates in the gigabit range and considerable reliability even with high utilisation. This real-time wireless communication will make many smart factory applications possible for the first time.

One scenario to be tested in the pilot phase under real-life laboratory conditions in Wolfsburg is the wireless upload of data to manufactured vehicles. With ever-higher levels of digitisation and fully connected vehicles, the production process requires large amounts of data to be transmitted to the cars. 5G makes it possible to perform this much more quickly, and at any time during production, the company said.

Transparent Factory In Dresden

A pilot factory for the Volkswagen brand that is testing innovative technologies in normal operation for the pilot-scale ID.3 series, a 5G island, has been put into operation at the Transparent factory in Dresden. In addition, networked control for a driverless transportation system is being developed further in collaboration with Porsche, Audi and the Dresden University of Technology. The sensors in the driverless transportation system transmit the environment data to cloud computing using 5G. This calculates the route to an ID.3 body and sends back the information in real-time. The project in Dresden is funded by the German Federal Ministry of Education and Research.

Christian Vollmer, Member of the Board of Management, Volkswagen Brand (responsible for Production and Logistics), said, “Our goal is to continuously optimise our production and make it even more efficient and flexible. We believe that 5G technology has great potential for innovation, from the use of intelligent robots and driverless transportation systems to networked control of plant and machinery in real time up to wireless software flashing of manufactured vehicles.”