Leading EV battery technology provider OneD Battery Sciences has introduced a new technology SINANODE, which can power the next generation of EV batteries.

To deploy SINANODE, the company also announced its pilot programmes, providing EV OEMs with their dedicated plant to deploy this technology, creating differentiated nano silicon configurations for its high-performance Li-ion batteries vision and 2024 EV production cycle ambitions.

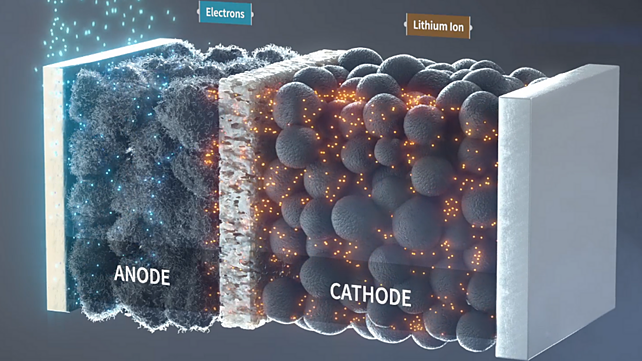

Interestingly the new technology can seamlessly integrate into the existing manufacturing processes to fuse silicon nanowires onto commercial graphite powders, a process that was a longtime challenge for the EV industry while building a battery with more silicon.

It results in tripling the energy density of the anode while halving its cost per kWh. The higher energy density increases battery range while nanowires shorten charging time. This enables the vehicle makers to design and produce electric vehicles that answer the booming market demand for better batteries.

Vincent Pluvinage, CEO, OneD Battery Sciences, said the EV demand will be driven by range, charge time, and cost, and the SINANODE technology addresses each of these purchase drivers in a significant way. As a result, the 2025 winners of the EV race will be powered by the only technology equipped to get the most silicon into the battery.

Over the last three years, leading graphite suppliers, cell makers, and EV makers in the US, Europe, and Asia, have tested SINANODE by applying the technology to commercial EV-grade graphite used in the anodes of EV batteries.

Some of the key findings and benefits include increased range and battery life since SINANODE fuses silicon nanowires to commercial graphite powders from multiple suppliers and tripled the anode specific capacity. Its anode material can then be blended with graphite to achieve high initial Coulombic Efficiency (to > 92%, a key metric used in matching anodes and cathodes) and a higher anode specific capacity over more than 1,000 full charge/discharge cycles than any state-of-the-art EV cells in production today.

The technology also helps contain the cost of EV anodes (measured in $ per kWh) by almost 50%, compared to the cost of most competitive anodes used in EV batteries today.

In addition, the seamless integration with increased performance of this technology can be deployed with multiple existing suppliers in multiple continents to leverage their enormous investments and the supply chain strategies of the leading participants in the fast-evolving EV industry. Rather than replacing existing suppliers, adding SINANODE replaces inefficient steps in the current processing of silicon additives with a scalable technology that increases performance and decreases the costs of the materials and cells used in EVs.