As the President of AIFI, Vikas Bajaj is responsible for strengthening the member base, driving strategic alliances and representing AIFI with various government bodies and other stakeholders. In his personal capacity, he is the Managing Director & CEO of Bajaj Motors and is also involved in the activities of Microtek Forgings.

Many industrial segments use forging – what are they? Which one dominates and why?

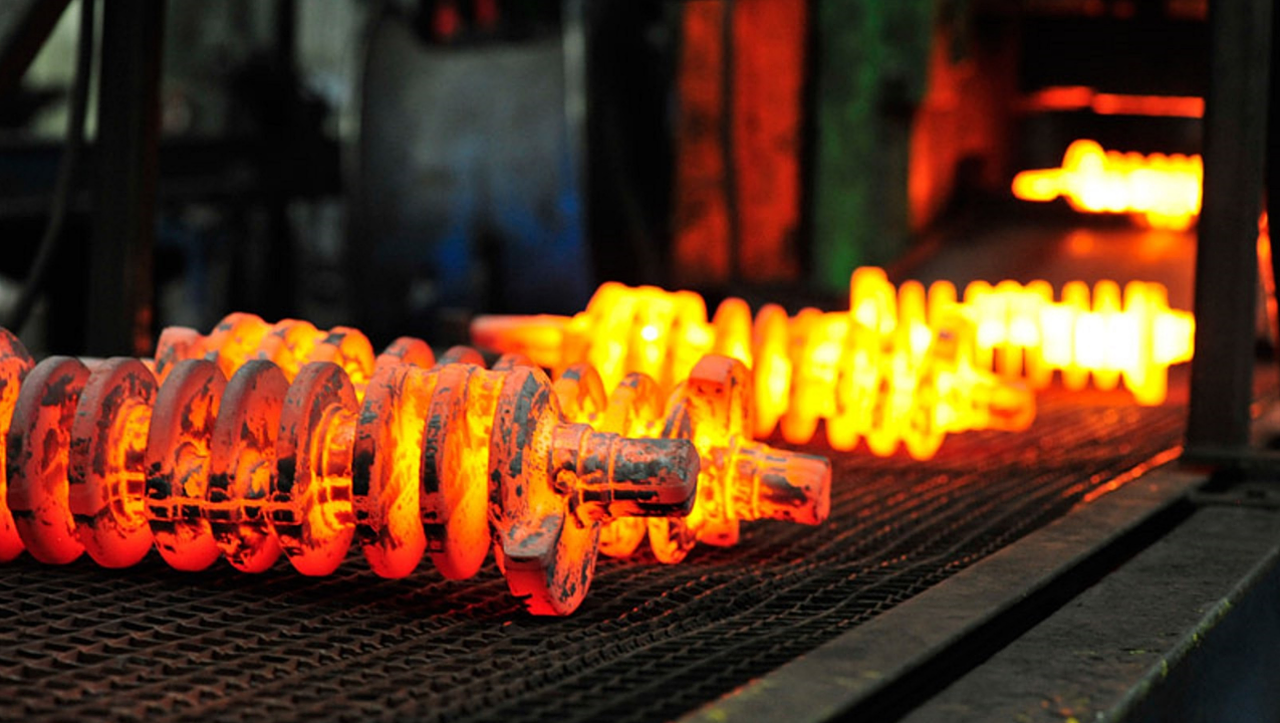

Forging is traditionally considered as the backbone of the manufacturing industry. It is a major input to the sectors that support the nation’s economic growth, such as automobile, industrial machinery, power, construction & mining equipment, railways, and general engineering. I believe that the auto sector would have a significant lead due to the product’s increased strength over castings. Most of the nuts and screws are also net shape forgings; thus, forgings can be imagined.

How are your members preparing for the second wave of COVID?

The situation remains the same as it was in the first wave; however, it has helped our members be much more equipped and hands-on with the work from home atmosphere. Our members, like many companies, are now able to operate the second wave of COVID seamlessly through the help of our online platforms, which makes work seamless.

Fortunately, the industry is not being forced to close because we provide a wide range of essential goods and services, and most members have an export order book. However, we are still dealing with migrant labour, and the second wave has resulted in a severe shortage of steel mainly because of no imports and the availability of oxygen for steel production.

Also, while we support the government’s decision to limit oxygen supply to industry and divert it to meet rising demand for medical oxygen amid a record number of coronavirus infection cases in the country, it has impacted the domestic forging industry. This is because the steel mills rely on oxygen supplies, and the forging industry is dependent on them for rolled steel.

Member companies are adhering to all health protocols during these difficult times. In addition, there was a lot of tech integration during the initial lockdown, which is now being extended and aiding employees in overcoming the challenges.

Trade wars between different nations seem to have given an edge for Indian manufacturing companies. To what extent it helped the forging industry?

Yes, the forging industry has an edge because many international OE’s have de-risked themselves from other manufacturing countries like China. Thus, many enquiries came into India. Certain experts predicted that several companies would wind up their operations from China and relocate to India. Many companies did wind up their production units from China, but they did not turn to India.

Instead, they moved to Vietnam, Thailand, Bangladesh, and Myanmar due to steel shortages and increases in steel prices in India, supply chain concerns, and the lack of export containers – making it difficult to pursue many export opportunities.

What are the average exports of forging from India during the past five years, and how has this changed with new opportunities?

The industry is increasingly addressing opportunities arising out of the growing trend among global automotive OEMs to outsource components from manufacturers in low-cost countries. As a result, the industry has been making significant contributions to the country’s growing exports. Average exports of forging from India during the past five years have grown by 40%.

What challenges are faced by the forging industry, other than COVID, and how has AIFI helped mitigate these issues?

Apart from COVID, the key challenges we experience include a lack of skilled manpower, insufficient power supply, increasing power prices, and a lack of modern equipment among small and tiny companies.

To address these concerns, we hold sessions with experts, who can guide members. In addition, AIFI’s interaction platform assists our members in exchanging ideas, notes, data, and innovative forging methods. We also hold discussions and surveys to identify issue areas and provide solutions such as automation and process optimisation that would mitigate the issues raised.

The cost of forging has increased, but the government has not announced any compensation; we anticipate a favourable decision in this regard.

What do you have to say about the increase in steel prices?

Recently, we have urged the government to ban steel and iron ore exports, as domestic steel prices shot up 25-30% in the last three months due to increased exports and squeezed supply in the local market. As the initial increase was impossible to sustain, the further hike in prices will be disastrous.

Increasing steel prices have put the forging industry at serious risk, particularly when recovering from COVID-inflicted business losses, exerting pressure on cash flow and cash reserves.

Currently, the industry is still going through a tough time and is not able to absorb losses. I believe that rising demand for steel, low steel production for the domestic market due to increased steel exports are the prime reasons for price hikes. If Indian steel prices are higher than international steel prices, that will lead to exports becoming uncompetitive. Export rates have risen sharply post-COVID, and they have almost doubled.

Steel export is one of the major reasons for the rate hike. Large mills prefer to export steel to neighbouring countries. Also, orders have been booked for Europe, the Middle East, etc. Thus, steel companies are able to increase prices at their will due to the gap in supply and demand.

What does AIFI expect from the government?

The government needs to invest more funds in major industries, including infrastructure, real estate, manufacturing, and tourism, to emerge from the COVID 19 pandemic and increase employment. In addition, there is a need to increase the existing incentives to increase exports. There is also a need to speed up refunding the GST to provide the industry with liquidity. Besides, the highest tax rate under the GST legislation must also be minimised by up to 18% to boost demand.

Also, being a core sector in India, we would be delighted if the government introduced forging courses at colleges. We also expect that power rates be uniform across India, soft loans are made available to SMEs for technology upgrades, steel prices be regulated, and a worldwide benchmark institute is established to enhance the existing talent pool in quality management and cost optimisation atomisation, etc.

What is your view on the vehicle scrappage policy?

The incentives and benefits, which will be received from the policy, will encourage more people to buy new vehicles. This policy might give employment opportunities in the forging as well as automobile sector.

What are the learning from the forging industry associations in the USA, Europe, Japan, China and others?

Every country has its own association, and AIFI has a very healthy and interactive relationship with all of them. IFC, Asia Forge, and Forgetech are exhibition platforms, where global players can participate, present learning papers, share new technologies, collaborate, exchange ideas, and understand global trends in the forging industries. When these exhibitions are held in other countries, the plant visits are very interesting and provide a great understanding of how plants run.