In the ever-evolving landscape of sustainable transportation, the fuel delivery system emerges as a critical yet often overlooked component, serving as the heartbeat of a vehicle's power generation process.

Fuel Delivery Systems

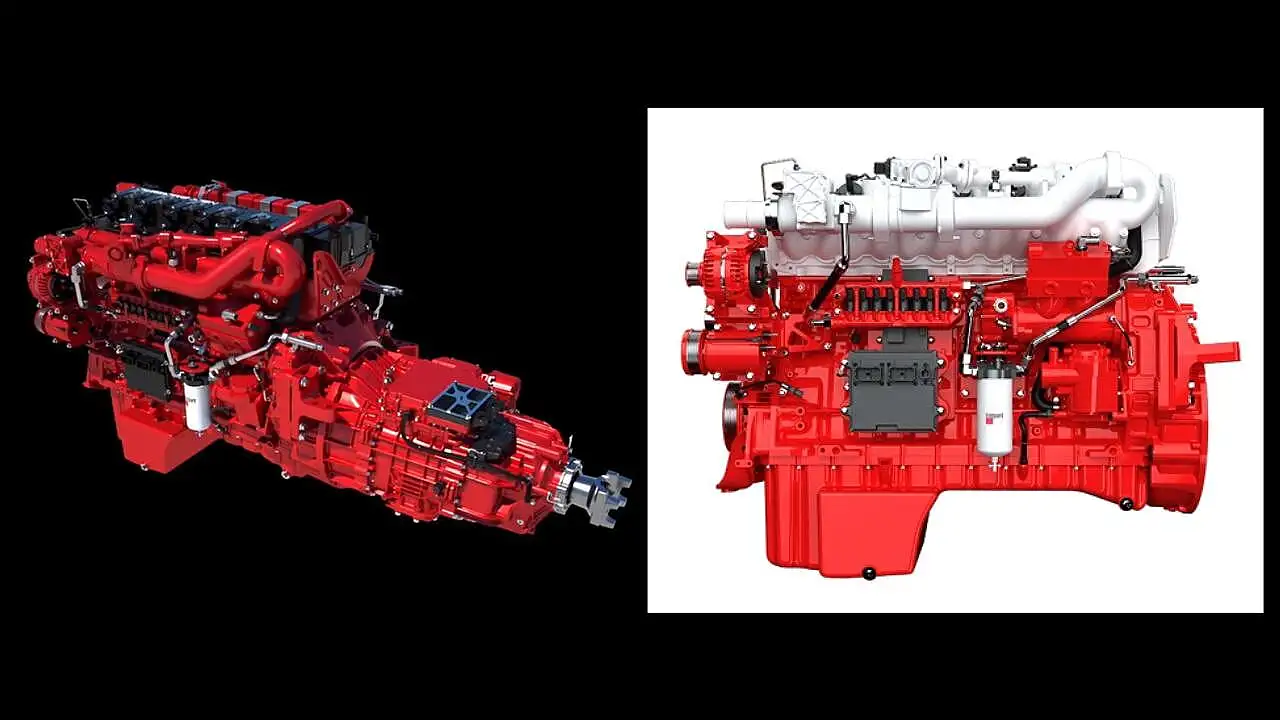

At the recently concluded Bharat Mobility Global Expo 2024, held in New Delhi, Cummins India displayed one of the Hydrogen ICE engines to demonstrate how the fuel-agnostic architecture utilises a common base engine, with the application of innovative technologies.

From Hydrogen vehicles standpoint, there are several options for fuel delivery systems. At the core of Cummins’ hydrogen-powered vehicles lies a specially designed storage tank crafted from carbon fibre. Capable of withstanding pressures of up to 700 bar, this cylindrical vessel ensures the safe storage of hydrogen, a fuel known for its high-energy content and low density.

How different is the fuel delivery system in natural gas vehicles? While Cummins’ natural gas engine operates at lower pressures compared to hydrogen, its fuel delivery system can store gas at pressures of up to 300 bar. The storage tank remains a pivotal component for natural gas vehicles.

Hydrogen vs Natural Gas Systems

The on-tank valve in Hydrogen is an electrically controlled, which regulates hydrogen flow to the engine and aids in the swift and secure refuelling process. Equipped with safety features, including a thermal pressure relief device (TPRD), it ensures the system's safety and integrity.

In the case of natural gas, the system has mechanically operated on-tank valves offering distinct characteristics compared to their hydrogen counterparts.

The high-pressure regulator in the Hydrogen engines conditions the hydrogen to suitable pressure levels for energy generation. Here, the high-pressure regulator plays a crucial role in enhancing both safety and efficiency.

The high-pressure regulator in natural gas vehicle performs a similar role as in hydrogen systems; the high-pressure regulator for natural gas reduces fuel supply pressure for optimal engine delivery.

Considerations

Sealing techniques, material selection, material coating, and testing are critical considerations in choosing fuel delivery systems. Hydrogen's smaller molecules pose unique challenges, requiring precise sealing mechanisms, materials resistant to embrittlement, and thorough testing to meet global standards.

As the transportation industry transitions towards sustainability, the fuel delivery system takes centre stage. From hydrogen internal combustion engines to natural gas vehicles, it embodies cutting-edge engineering, paving the way for a future where eco-friendly mobility is not just a concept but a tangible reality. According to Cummins it stands ready to collaborate with manufacturers and fleets on this transformative journey towards cleaner and more efficient fuel technologies.

Also Read:

Cummins, Tata Motors Ink New Partnership For Green Energy Tech