Nevertheless, serious challenges facing automakers and their suppliers this past year, four of the six major US and Japanese automakers improved their scores in the 21st annual North American (NA) Automotive OEM - Supplier Working Relations Index (WRI) Study.

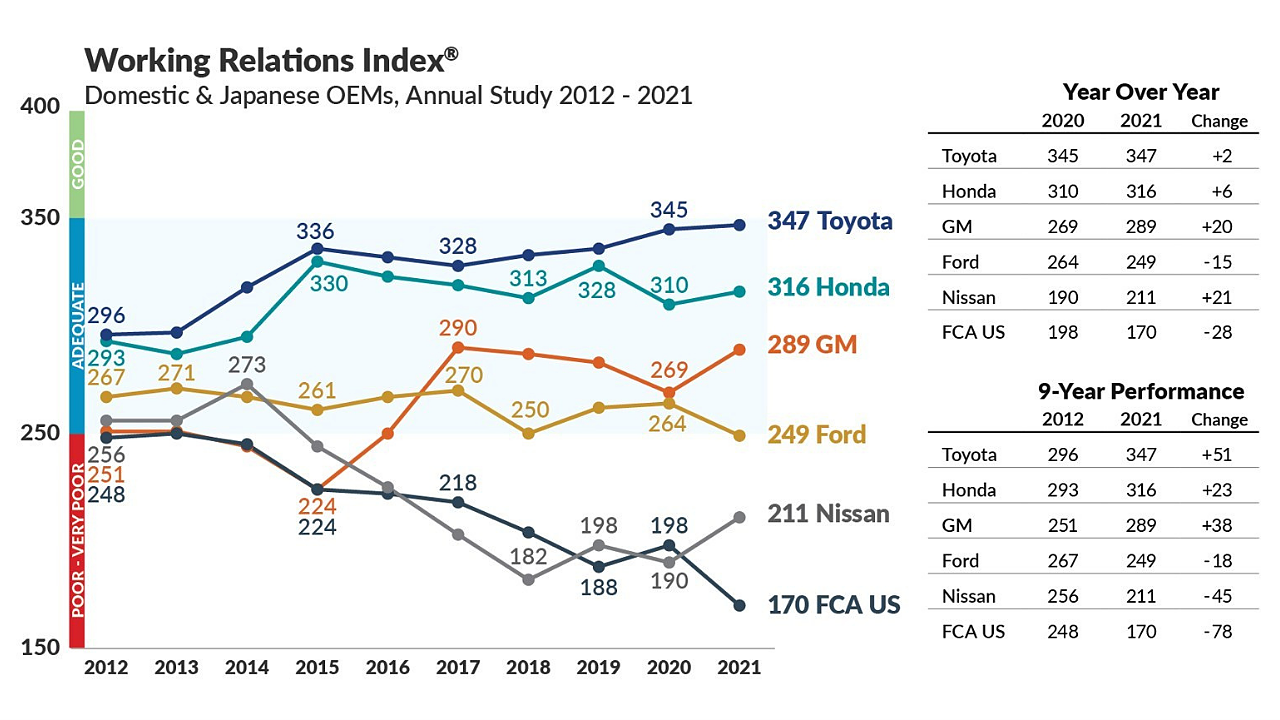

The study, conducted by Plante Moran, states that the top three scorers again this year on the WRI graph were Toyota at 347 and Honda at 316, who gained only two and six points respectively, and General Motors in third place. GM jumped 20 points to 289, further distancing itself from Ford in fourth place, which dropped 15 points to 249. Nissan scored only 211 but gained 21 points – enough to retake fifth place from FCA/Stellantis, which lost 28 points and is in a distant last place in the rankings at 170.

The annual study is conducted by Plante Moran and this year ran from mid-February to mid-April. Respondents represented 728 salespersons from 479 Tier-1 suppliers, representing about 50% of the six OEMs' annual buy. Demographically, the supplier-respondents represent 41 of the Top 50 NA suppliers and 64 of the Top 100 NA suppliers. The study is watched carefully by automakers because their supplier relations rating on the WRI is highly correlated to the benefits that the OEM receives from its suppliers, including better pricing, more investment in innovation and technology, more sharing of technology, and better supplier support, all of which contribute to the OEM's operating profit and competitive strength.

Dave Andrea, Principal in Plante Moran's Strategy and Automotive & Mobility Consulting Practice, said, 'Without a doubt, the industry went through a trial by fire this past year, but seeing the positive results for four of the six automakers was a surprise in many ways. Typically, a crisis is not the time to improve established relations, but the OEMs' efforts to enhance mutual trust, transparency, and communications moved relationships forward through the worst of COVID-19 and the stop and restart of their operations.'

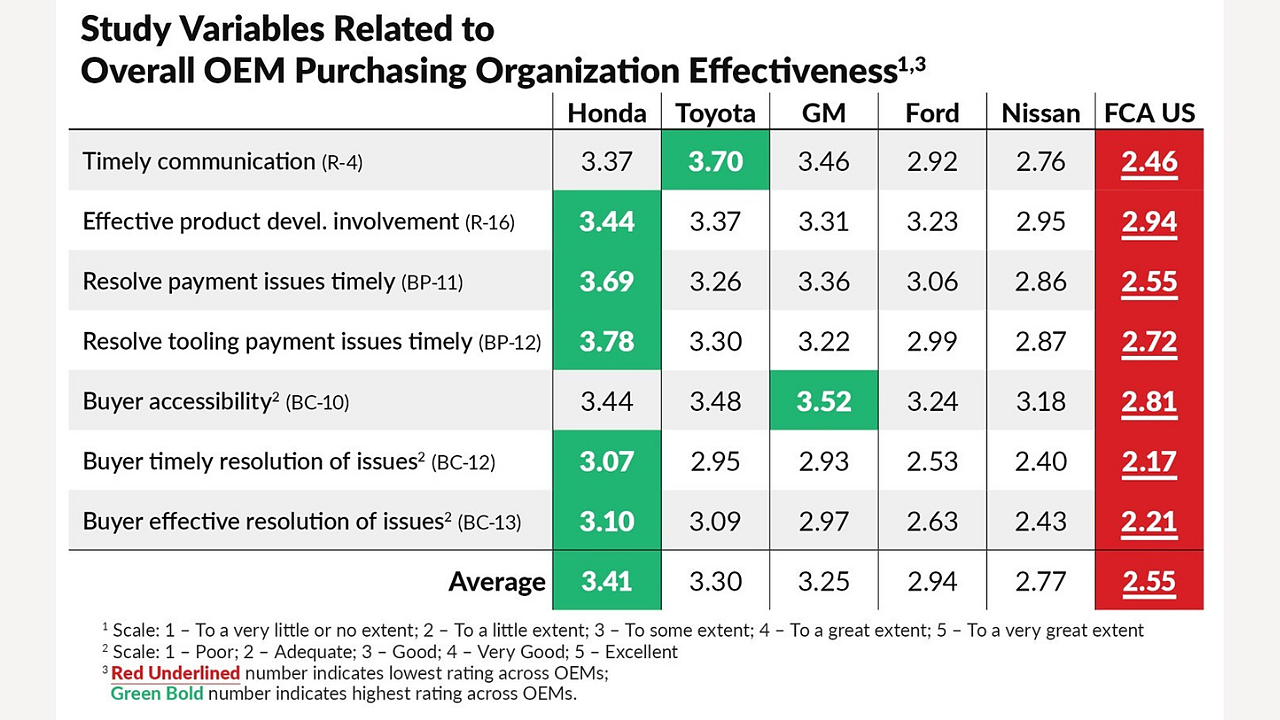

'The automakers will have to continue building on these fundamentals to survive near-term parts shortages like the scarcity of microchips and truly deepen relations to support the development of electric vehicles and related technologies in-house or out-sourced or through acquisitions or partnerships. These industry challenges put more pressure on purchasing organisations to respond and resolve issues more effectively,' he said. The WRI survey identifies specific supplier feedback on many attributes contributing to a purchasing organisation's throughput effectiveness. Looking across these attributes, Honda is rated the best in purchasing effectiveness overall, Toyota in second and the others following in the same order as the 2021 WRI rankings.

'We're often asked by automakers what's the key factor – the 'silver bullet' – that will improve their Index ranking,' said Andrea. 'The answer is: there isn't one simple thing. It's making many small, incremental improvements to the foundational elements over time – such as paying invoices and training knowledgeable buyers – and aligning top leadership and all functions to support value-add by the supply chain.'

A nine-year comparison of the OEMs' performance supports this premise. Although Toyota only gained two points this year, its corporate mantra of 'continuous improvement' has paid off with a 51-point gain since its low point in 2012, while GM improved by 38 points, and Honda, 23 points. But, over the same nine-year period, Ford dropped 18 points, Nissan was down 45 points, and FCA/Stellantis fell 78 points.

OEM-supplier trust and communication

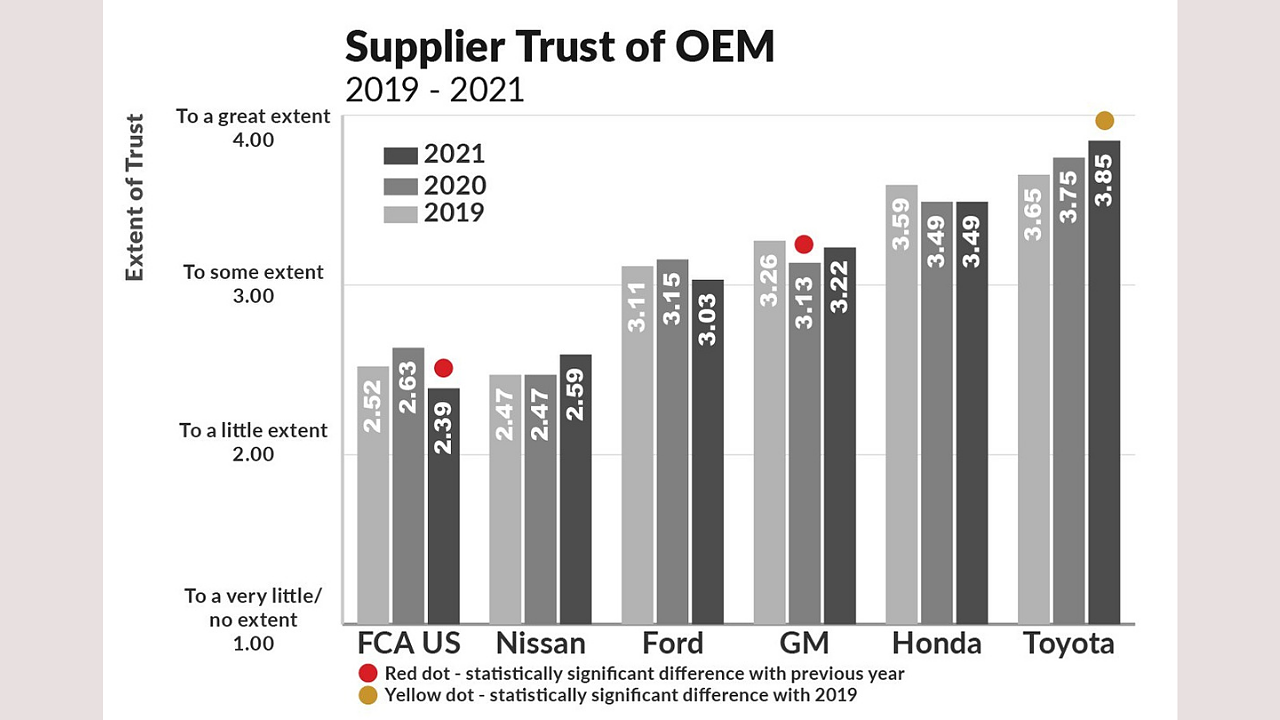

The Study has shown the cornerstone of good working relations to be trust and communication, particularly important factors in the current uncertain business environment with billions of dollars and thousands of jobs at stake. Figure 2 shows how suppliers have ranked the six automakers in terms of trust over the past three years. The three-year average of Supplier Trust of OEM shows Toyota first with significant improvement; Honda and GM relatively steady at second and third; Ford down slightly at fourth; Nissan gaining and in fifth place and FCA/Stellantis dropping significantly this year to last place.

More trust, more benefits

The level of perceived trust and communication of OEMs by suppliers when dealing with their customers is directly correlated to benefits the OEMs receive from them. These two factors also play a major role in which OEM is the beneficiary of suppliers' willingness to invest in new technology in product development activities. This year, GM took over first place from Toyota in supplier willingness to invest in technology, with Nissan is up significantly but still in the last place.

Purchasing

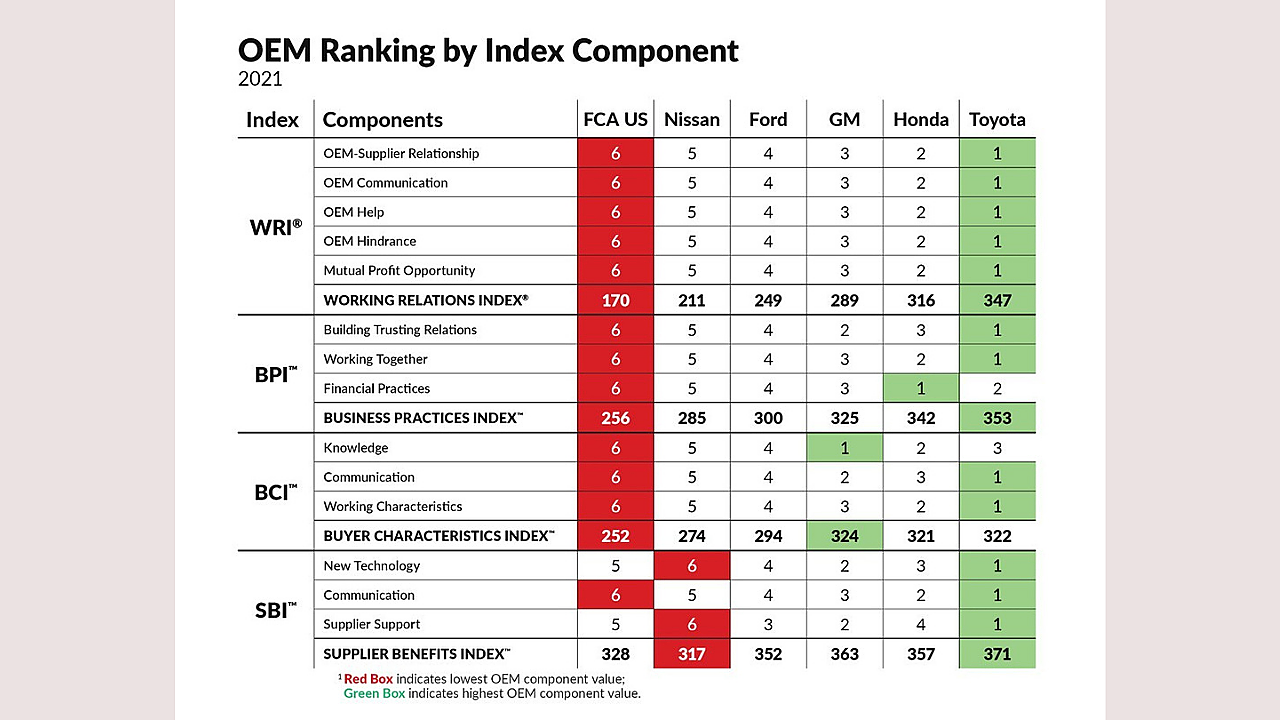

The rankings in the overall WRI provide high-level insight, but the study also delves deeply into OEMs' specific purchasing areas. By examining each specific area, management can determine where improvements are needed.

Toyota ranks best in seven of the eight specific purchasing areas with Honda best in Body-in-White. It is especially noteworthy that in the two most important areas going forward -- autonomous vehicles and EVs -- Toyota ranked highest in EV & Hybrid Powertrain and Electrical & Electronics.

Engineering performance impacts supplier relations

For a number of years, automakers have been trying to speed time to market, lower cost, and improve quality by having departments involved in product design, development, engineering and purchasing work more closely and streamline decision making.

The OEM's engineering organisation causing unnecessary costs is falling at five of the six OEMs with Toyota and Honda doing the best job, but Ford is challenged in this area.

Further, the study asks suppliers to rank the OEMs on the degree they feel they receive conflicting objectives between purchasing and engineering, leading to higher costs. This includes late or excessive engineering changes, whether the supplier is given enough flexibility to meet cost and quality objectives; and if the supplier is involved early enough in OEM product development -- and kept involved throughout the process. All of these are critical to reduce cost, improve quality, and speed time-to-market. Although still number one in this area, Toyota lost some ground, and Honda improved in 2021.

Courtesy: Plante Moran