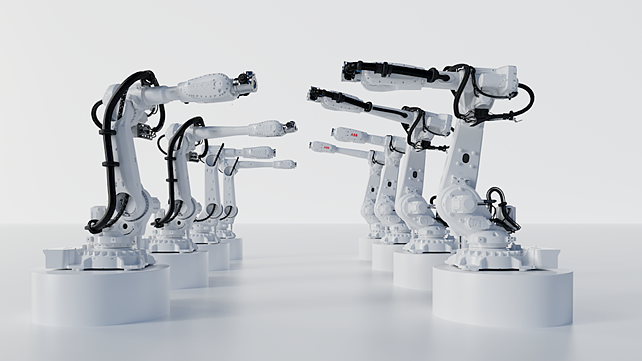

Addressing the unique requirements of complex manufacturing applications, including electric vehicle production with added speed and flexibility for material handling, the engineering service company, ABB, has launched two new robots - IRB 5710 and 5720.

Both robot families are powered by the company’s new OmniCore controller V250XT, featuring ABB’s TrueMove and QuickMove motion control technology.

This enables the IRB 5710 and IRB 5720 robots to offer class-leading speed, improving production capacity with lower manufacturing times. In addition, with their position repeatability (0.04-0.05mm), path repeatability (0.1-0.14mm), and path accuracy (1-1.2 mm), these robots are more accurate than others in their classes, enabling them to deliver the highest levels of manufacturing quality, the company claimed.

Further protection against damage and cable wear and tear is provided by its LeanID Integrated DressPack, which enables process cables to be routed inside the robot’s upper arm and along the wrist rather than externally. Moreover, both robot ranges have multiple mounting options, including floor, angled, inverted and semi-shelf for maximum production design flexibility.

Available in eight variants, the new robots present a choice of options for payloads from 70kg to 180kg and reaches from 2.3m to 3m, the company said.

The two robot families are suitable for a wide range of production tasks, including material handling and machine tending and assembly, and specific operations in EV manufacturing such as battery module picking and placing, high precision assembly, and parts handling.

These robots can also be used in plastic moulding, metal casting, cleaning, and spraying applications. More process applications such as welding, cutting, or dispensing will be released in 2023, a release from the company stated.

Joerg Reger, Managing Director of ABB Robotics’ automotive business line, said that the switch from internal combustion engine (ICE) vehicles to EVs especially is driving increased demand for fast, adaptable production lines.

“EV designs can often be highly complex, and components such as batteries and semiconductor modules can be very heavy or extremely fragile. These demands call for solutions that can offer maximum precision and repeatability to avoid errors in production,” he added.