Britain’s leading car salvage, dismantling, and recycling company, Synetiq, has said that it extracts over 5,200 tonne of aluminium during the vehicle recycling process each year. This is enough to create 346 million drinks cans. The company also redistributes the metal back into the supply chain as part of its integrated, circular recycling model.

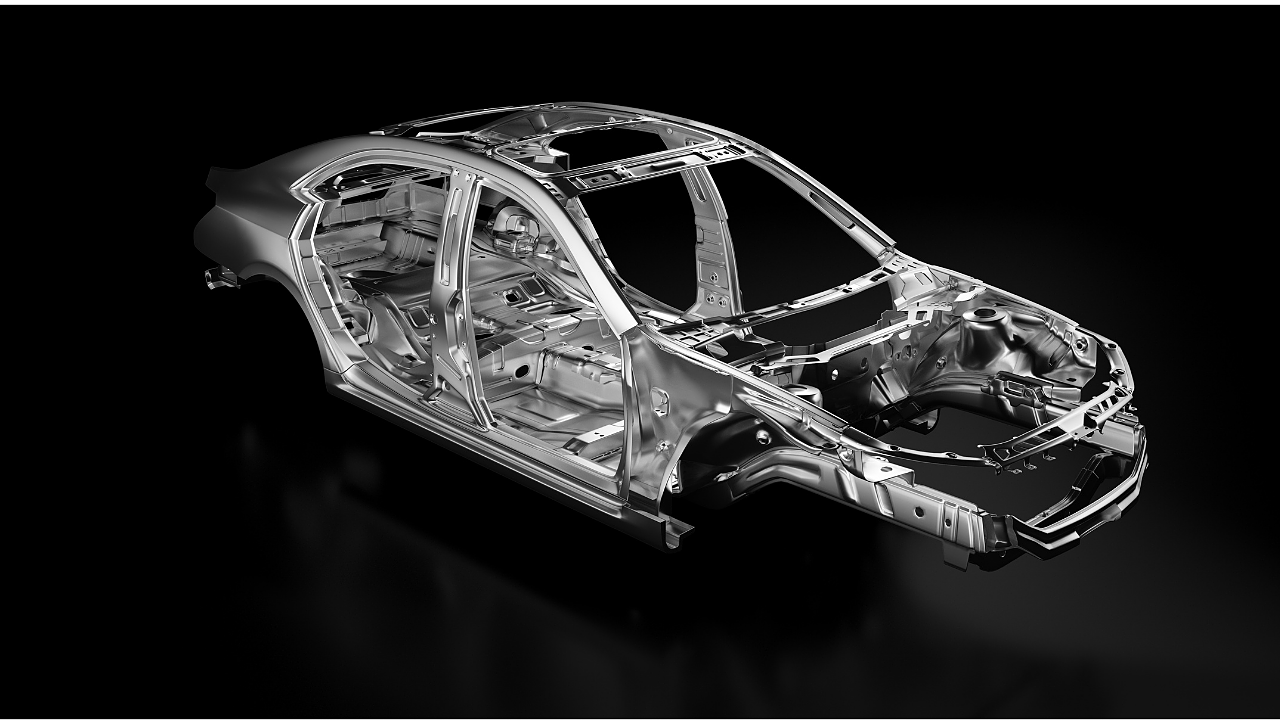

Aluminium is commonly used throughout modern vehicles, including body panels, wiring, wheels, engine and transmission. The challenge is to carefully separate during the recycling process.

Aluminium is a versatile material; its strong and lightweight properties make it perfect for a range of reuses, whether manufacturing beverage cans and cooking foil or aerospace and alloy wheel manufacturing.

Synetiq processes more than 70,000 vehicles each year, using the waste hierarchy of reducing, reusing, remanufacturing, and recycling to maximise operations sustainability. Vehicles that are not safe for repair, and do not contain reusable parts, are separated into raw materials for recycling.

Over the last two years, the business has helped clients avoid 5.5 million kgs of CO2 through the supply of green parts alone – the equivalent CO2 of powering 662 homes for one year.

Part of Synetiq’s initiative called ‘Our Road to Tomorrow’, to be the sustainable business in its sector, the initiative included a study into the actual CO2 footprint of its operations and the CO2 savings that can be achieved by using green parts in automotive repairs, while highlighting the environmental benefits of integrated salvage and recycling.

According to Ray Curry, Operations Director at Synetiq, aluminium recovery is a critical element of this process, as the material is 100% recyclable. It creates new CO2 savings every time it recycles it.

Using recycled aluminium reduces CO2 emissions by 92%, compared to raw material use, and saves 95% of the energy needed for primary production, according to a 2020 report by the European Recycling Industries’ Confederation (EuRIC AISBL – Metal Recycling Factsheet -2020).