Beginning with a small factory in Hanover in 1871, Continental has developed into one of the global players in the automotive industry, now operating in 58 countries and markets.

The German company is the oldest independent and also one of the largest tyre manufacturers in the world. During the last 150 years, it has set standards in the tyre industry with its innovative strength.

On October 8th, 1871, the “Continental-Caoutchouc- & Gutta-Percha-Compagnie” was incorporated. The product range initially included several rubber products, including toy balls, rubber mats, roller coverings, rubberised fabrics and solid tyres for carriages and bicycles.

Beginning with bicycles

When the bicycle began its worldwide career in 1892 with freewheel and coaster brake, Continental was the first German company to produce pneumatic bicycle tyres and thereafter, 'pneumatics' soon became a household word.

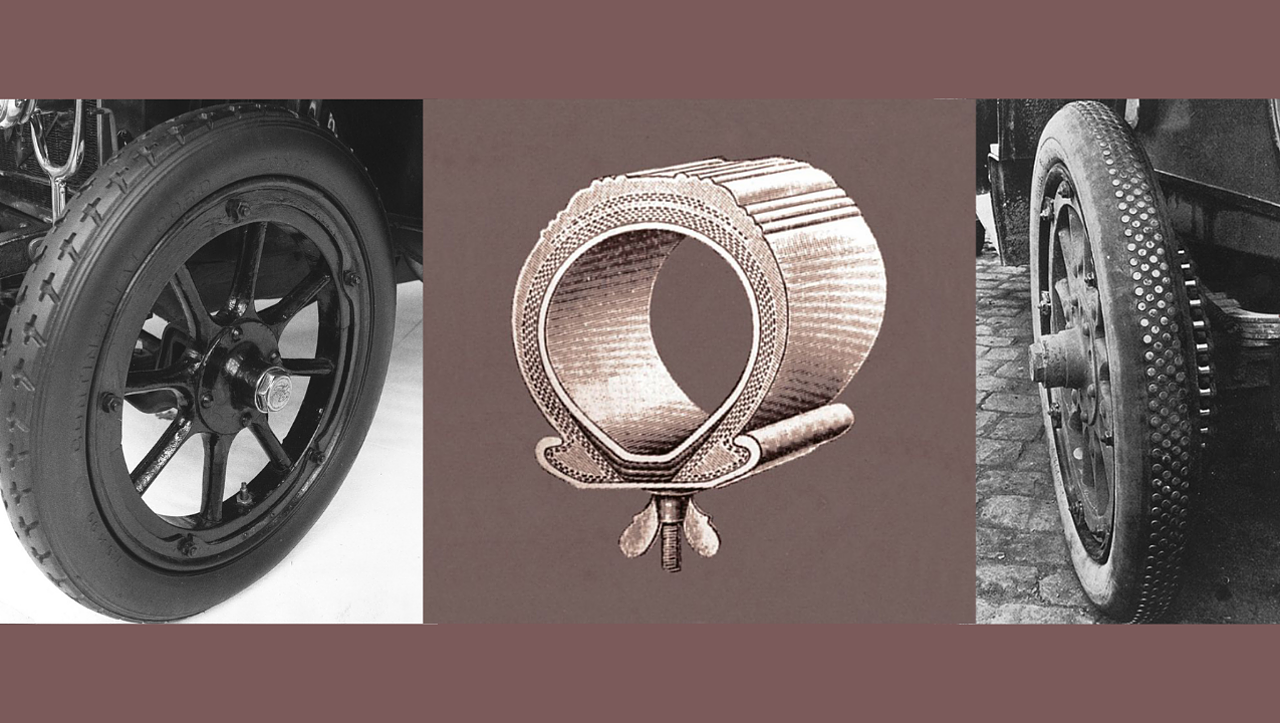

In 1898, the production of pneumatic tyres for cars also began. However, the first pneumatics were still treadless and had comparatively limited handling characteristics by today's standards, especially on wet or wintry roads. All tyre manufacturers were looking for solutions to the sliding susceptibility of their products – until Continental presented the world's first car tyre with a tread in 1904.

Fiftieth anniversary

To mark its 50th anniversary, the technology company launched large tyres for commercial vehicles. In 1928 the company, for the first time, manufactured tyres for agricultural tractors and traction machines. Eventually, the T2 agricultural tractor tyre became the first pneumatic agricultural tyre in Europe. In 1932 the German firm introduced ContiSuperElastic solid rubber tyre. Its success led to the abbreviation for this category that is customary in the industry today, which is 'CSE.'

Another milestone in the industrial history of the 20th century is the first tyre made of synthetic rubber, which rolled out of Continental's factory in 1936. Then, under the effects of the shortage economy during the war years, the tyre maker introduced the first research series to obtain rubber from Russian dandelions. Finally, in 2011 it undertook the project which saw 'Urban Taraxagum' bicycle tyre as the first one by Continental made in series production using rubber from dandelions.

Tubless tyres

In 1943 Continental filed a patent application for the tubeless tyre. An invention that significantly improved the rolling resistance became a common technological principle in the post-war period and still is today. Continental first enabled particularly safe driving in winter in 1934 with its 'all-terrain' model, its first dedicated tyre designed for snow and thus its first winter tyre.

Testing

In 1953 Continental crossed the snowy St. Gotthard Pass in Switzerland with its M+S tyres (mud and snow) under notarial supervision, successfully completing the first winter tyre test in history.

For regular testing of tyres and all conceivable conditions, the company maintains state-of-the-art testing facilities worldwide. The Contidrom near Hanover, the 'prototype' and reference of all Continental tyre test centres, was opened in 1967.

As early as 1968, the first electronically controlled driverless car took to the track at the Contidrom, to the astonishment of the public. It has further developed this technology and now uses it at its test site in Uvalde, Texas, USA, to subject its tires to endurance tests.

Digitalisation

To ensure that tyres are safer, more efficient, and sustainable, the company began sharpening its focus on digitalisation. In 1999, the tyre maker demonstrated that the data required for advanced driver assistance systems (ADAS) could help determine even more accurately and quickly if the tyre is used as a data source. And the intelligent tyre was born.

Meanwhile, the technology firm connected its tyres and sensors to the cloud and offered its customers completely new, smart, and digital solutions and services.

The road ahead

Now, the tyre manufacturer intends to gradually switch to 100% sustainably produced materials in its tyre products by 2050.

Today, Continental uses the direct connection of its tyres and sensors to the cloud to offer entirely new business models. Fed by a large number of data points, the company's fleet customers can check the condition of their tyres at any time using algorithms developed in-house. This means that tyre maintenance can be carried out on an as-needed basis, not as a preventive measure, and thus much more efficiently.

Fleet providers, therefore, benefit from minimised downtime due to repairs, increased safety, lower overall costs due to greater energy efficiency, and generally more efficient operation.

In 2020, Continental set new standards with its successful pilot project presentation for significantly accurate tread depth monitoring using algorithms and vehicle telemetry data.

In the future, the technology conglomerate aims to stand for innovative excellence in tyre technology with its premium portfolio in the passenger car, truck, and special tyre segments. In its new strategy programme presented in 2020, it describes its path into the new decade. The focus of the Vision 2030 strategy programme is the consistently customer-centric orientation of the organisation and all business activities. In addition, the tyre sector aims to continue to grow profitably and differentiate itself from its competitors in a rapidly changing market environment in the areas of sustainability and digital solutions.

Christian Kötz, Head of the Tires business area and member of the executive board of Continental, said, 'Time and time again, we push the boundaries of what is possible. Our goal is to produce our entire product portfolio exclusively from sustainable materials in a climate-neutral way by 2050 at the latest.'