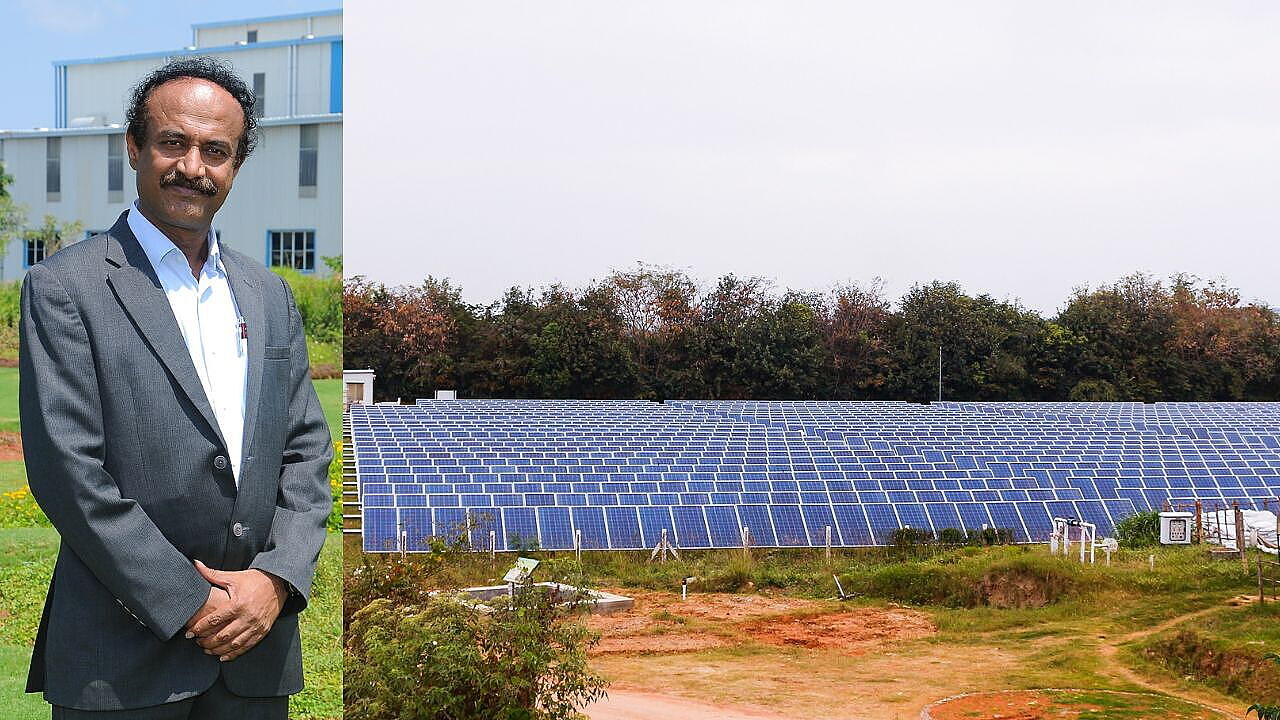

Raju Bhauso Ketkale is keen that Toyota Kirloskar Motor’s facility at Bidadi near Bengaluru becomes carbon neutral by 2026.

As Executive Vice President, Function Head — Manufacturing, he is particularly pleased that the Indian operations are now leading in “many areas” when compared to Toyota Motor Corporation’s 50 plus facilities worldwide.

“The common enemy is carbon and on the product side we really need to continue working on carbon neutrality and reduce the footprint. Plants have an opportunity to help out too, especially in areas like the paint shop,” Ketkale told Mobility Outlook in a recent interview.

As he explained, energy intensive operations clearly impact the environment and it is, therefore, imperative to keep these in check across the automotive ecosystem. “We need to take things forward and have a clear mission in this area,” he said.

Over the last two decades, TKM has been working on aspects relating to waste reduction, kaizen etc. As Ketkale added, the first 10 years were focused on reducing wastage while the last 10 have seen technology play a big role in plants and products, water conservation and so on.

“Today, TKM is ahead in critical areas such as solar where we also share this with our 29 suppliers in Karnataka as also some dealers. Extending support to the ecosystem plays a big role more than merely confining it to the company,” he said.

TKM is “driving many activities” at Bidadi as part of the goal to reach carbon neutrality over the next three years which will put India in a pride of place on the Toyota map. It will also mean that the operations here will be close to a decade ahead of what the parent company has set itself as its timeline for carbon neutrality. In the process, power costs will fall which is welcome news from the viewpoint of profits.

TKM’s efforts have also become a reference point for some of Toyota’s operations especially in areas like solar power. “This is an India success story and has happened over the last seven years,” said a visibly pleased Ketkale.

With Suzuki as its key global ally, there is every likelihood that the duo will pull out all the stops when it comes to sustainability. While Toyota is the bigger player worldwide, Suzuki is the clear leader in India where the partners are already working on new projects and need to ensure that they keep their eyes on the carbon neutrality mission.

“We are sharing initiatives with each other and TKM is learning from Suzuki processes,” said Ketkale without getting into too much detail. For now, his top priority is to spread the message across the company’s vendor and retail networks. “Service areas like dealerships can also adopt best practices and it is important for us to contribute to society,” he added.

Incidentally, the Bidadi plant is home to the Toyota Ecozone defined as an “experiential environmental learning centre” spread across 25 acres within the TKM premises. The website terms it a “unique concept” that includes 17 educational theme parks designed to create a sense of ecological consciousness among children and various stakeholders.

In its recent Integrated Report for 2022, Toyota Motor Corporation has stated that it is taking on the challenge of creating a green factory on various fronts in order to achieve carbon neutrality by 2035. According to the company, this will present an opportunity to fundamentally innovate manufacturing which is an important component of the cleanup effort.

For instance, painting and casting are the most carbon-intensive automobile manufacturing processes. Based on new ideas, “we are taking on technological development focused on decarbonising the above two processes”.

As the Integrated Report explains, conventional air-spray technologies are designed to deposit paint over broad areas. Moreover, with the air blown toward the target surface rebounding off it and scattering paint particles, only approximately 70% of the paint being sprayed successfully adheres to the target surface while the remaining 30% goes waste.

To eliminate such waste, airless painting machines take advantage of the world’s first technology that uses static electricity to cause fine paint particles to adhere to the target surface. “This technology enables us to achieve a coating adhesion efficiency of more than 95%,” the company has stated.

Furthermore, having combined this technology with the innovative concept of a rotating paint ejection head, has made it possible to create even finer paint particles with minimal variation in size, thereby achieving even higher painting quality.

“In addition to curbing CO2 emissions from our manufacturing operations via the introduction of airless painting machines, we are also able to reduce the size of paint recovery equipment as the volume of waste paint is considerably smaller. Thus, airless painting machines will help us achieve a significant reduction in the volume of CO2 emissions,” quotes the Integrated Report.

Also, in an effort to upgrade the press moulding process for body panels, the Japanese automaker is striving to make use of in-mould coating technology in which paint is applied to body panel parts as they are shaped within the metal press molds. The integration of press moulding and painting into one process is “an epoch-making idea that can eliminate” the conventional painting process.

Other new ideas include replacing paint with adhesive film, effectively eliminating the painting process. Adhesive films can be customised to make them special, and they can also be replaced for fun. “Drawing on this idea, we intend to take on a new business in which we renovate used vehicles, make them look fantastic, and offer them to users,” says Toyota.

Also Read:

Toyota Hyryder Gets CNG Option For INR 13.23 Lakh

Manasi Tata Takes Over As Vice Chairperson Of Toyota Kirloskar

Toyota Exhibits Alternate Fuel Options At 25-hour Race In Thailand