As part of its initiative to cut development time by about a quarter, increase the speed of new software releases, and significantly accelerate manufacturing processes in production, Wolfsburg-headquartered Volkswagen Group is realigning its Technical Development (TD) division.

Functioning from Wolfsburg, the TD will transform the group’s largest engineering unit with 11,500 employees into a pace-setter for the brand’s transformation into a technology company. The main emphasis is on a complete redesign of the development process, making it interdisciplinary, focused squarely on software, customer requirements and SSP, Volkswagen’s electric platform of the future, and centred on functions rather than individual components. Going forward, TD will become a key pillar for the transformation of development for the group.

Containing Development Process

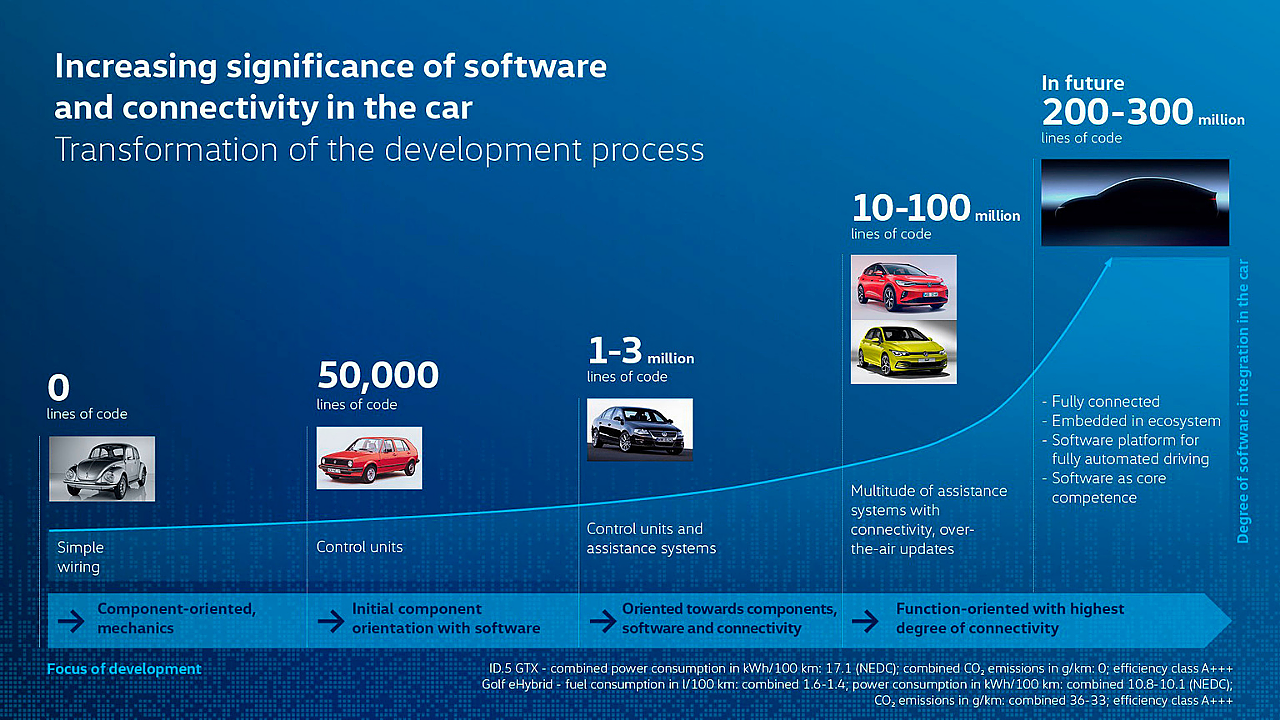

In the 1990s, vehicle development centred primarily on components. As functions and electronics were added in the early 2000s, connectivity began to play an increasingly important role. Now and in the future, the vehicle must be viewed as one system in the customer’s entire ecosystem and communicate seamlessly with all systems outside the vehicle. To this end, the experts from different specialist units clarify requirements and interdependencies early and ensure that systems and components are configured and designed appropriately so that all these functions can mesh seamlessly. In tandem with stepping up its focus on agile working methods, the group is thus reducing development times by 25%. In the future, it will make the group complete vehicle projects in 40 months instead of 54 months as before. In addition, TD contributes significantly to process-optimised manufacturing by working closely with production, targeting a possible production time of around ten hours per vehicle.

Honing Skills

By realigning TD towards connected development processes focusing on systems and functions, the group is making targeted investments in employee training to ready its workforce for the digital age. Several hundred employees have already undergone training for new fields of work in TD, and thousands more will do the same in the years to come. By 2030, about 4,000 employees will be re-skilled for significant new job profiles, while 6,000 to 8,000 more will be up-skilled, receiving extensive training.

Training opportunities range from shorter course units designed to broaden specific expertise to large-scale retraining. Currently, the longest training programmes last up to 180 days and will give employees the chance to work in new areas of activity. For instance, a skilled metalworker could become an automotive engineering commissioning specialist. In this way, the group is laying the foundations for attractive jobs and safeguarding jobs at its Wolfsburg location for the long term.

Foundations For Future Mobility

By accelerating the development process, focusing systematically on customer requirements and training staff for specific jobs, TD is setting the stage for future mobility and creating the conditions for developing a value-driven, all-electric, fully connected vehicle with Trinity that is seamlessly integrated into the digital ecosystem.

To this end, the group is working on the platform it will use in the future, known as SSP (Scalable Systems Platform). A robust and scalable platform for the electric age, this will be deployed for the first time in 2026 in Volkswagen’s Trinity project and will eventually merge the current MEB and PPE platforms. This will make the SSP the bedrock for all brands and models – in other words, the basis for more than 40 million Group vehicles – and allow Volkswagen to cement its positioning as a platform champion. Like MEB, SSP will also be open to third-party providers. At the same time, it will enable the vehicle to be fully integrated with its ecosystem, thus creating the conditions for high driving automation (Level 4) and new usage-based business models.

Digital Lifecycle Management (DLCM) will keep Volkswagen vehicles up-to-date even after delivery so that in the future, customers will have a vehicle that is always in step with the times. Volkswagen is making this progress affordable for many people as a volume manufacturer – technologies such as over-the-air updates (OTA) and functions on demand (FoD) are already living up to this claim.

By rolling out the ACCELERATE strategy, the Volkswagen brand will systematically prepare for the profound changes in the automotive industry in good time. The brand has earmarked around €18 billion for investment in the future trends of e- mobility, hybridisation and digitalisation up to 2026.

As part of its global electric offensive, the group will increase the share of its all-electric deliveries in Europe to over 70%. In the United States and China, the brand targets an EV market share of over 50% in the same period. Volkswagen will bring out at least one new BEV model every year to achieve this. The goal is the full electrification of the model portfolio.

The group intends to be net carbon neutral by 2050 at the latest. At the same time, the company is also accelerating the other significant issues of the future: Integration of software in the vehicles and the digital customer experience will become essential core competencies. In implementing data-based business models, Volkswagen seeks to attract new groups of customers and tap additional sources of income. In addition, the group will enable autonomous driving for many people by 2030.