More than 98% of manufacturing leaders expressed concerns about data-related issues within their organisations, reveals Hexagon, a global leader in digital reality solutions, combining sensor, software and autonomous technologies.

The global survey, conducted by Forrester Consulting, shows persistent data challenges hinder the implementation of advanced manufacturing technologies like digital twins, automation, and AI. Despite considering real-time collaboration and automation, manufacturers are facing obstacles that impede innovation and productivity.

Key Findings:

Data Quality and Availability Issues: Almost all manufacturers (98%) reported at least one data-related issue, affecting the adoption of advanced technologies.

Automation Lag: Nearly 40% of manufacturers are labelled as automation laggards, risking falling behind competitors prioritising data-driven productivity and automation.

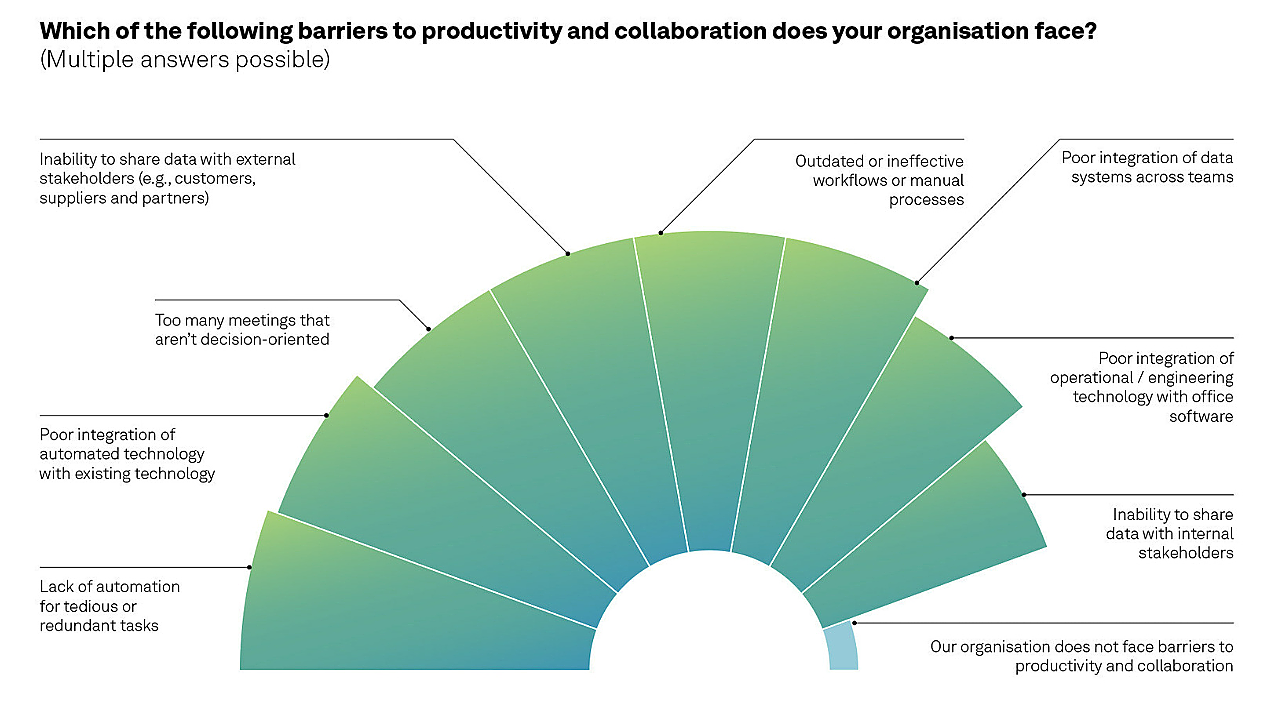

Collaboration Challenges: Data challenges contribute to 97% of manufacturers facing collaboration and productivity issues, impacting innovation and responsiveness to customer needs.

Concerns about Lack of Synergy: Business leaders are concerned about the lack of synergy between design and manufacturing teams, with 71% expressing worries about the collaboration gap.

Josh Weiss, President of Hexagon's Manufacturing Intelligence Division, Comments, said, 'It's ironic that manufacturing, the pioneer of automation, is struggling to transform. Achieving digitalisation in manufacturing is a real, complex, and human challenge. Those empowering their organisations with data now can drive efficient value creation, get products to market faster, and adapt to market conditions.'

Digitalisation Leaders vs Laggards

- 58% of leaders report increased staff productivity and innovation, compared to 35% of laggards.

- 39% of leaders effectively address talent shortages, compared to 26% of laggards.

Global Trends

- Asian manufacturers are more confident in applying their data, utilising simulation, virtual manufacturing, and predictive maintenance.

- 58% of Asian companies plan to invest in AI-powered automation over the next three years.

Conclusion: With only 2% claiming to be problem-free with their data practices, manufacturers must address data challenges urgently to meet business goals. The research provides valuable insights into the industry, highlighting trends and challenges, and emphasises the need for cultural and technical changes for successful digitalisation.

Courtesy: Hexagon. Featured Photo courtesy: Cooper Corporation.

Also Read:

ACMA's 'Transforming Mobility 2024' Summit Charts The Future of EV Component Manufacturing in India